Preparation method of lignin-based carbon nano enzyme with enzyme-like catalytic activity

A lignin-based, catalytically active technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high raw material costs, hidden dangers of experimental safety, cumbersome synthesis steps, etc., and achieve synthetic methods Simple, wide source of raw materials, strong water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] This embodiment is a preparation method of a lignin-based carbon nanozyme with enzyme-like catalytic activity, which is specifically completed according to the following steps:

[0018] 1. The preparation process of lignin-based carbon nanozyme: After adding 0.1g sodium lignosulfonate and 0.1g potassium chloride to 20mL ultrapure water, put the solution on a rapid mixer and mix evenly, then transfer the mixture into a stainless steel autoclave lined with polytetrafluoroethylene. Put the reaction kettle into an electric constant temperature blast drying oven, set the reaction time to 12h, and set the temperature to 180°C; after the reaction, take the reaction kettle out of the oven and cool it to room temperature;

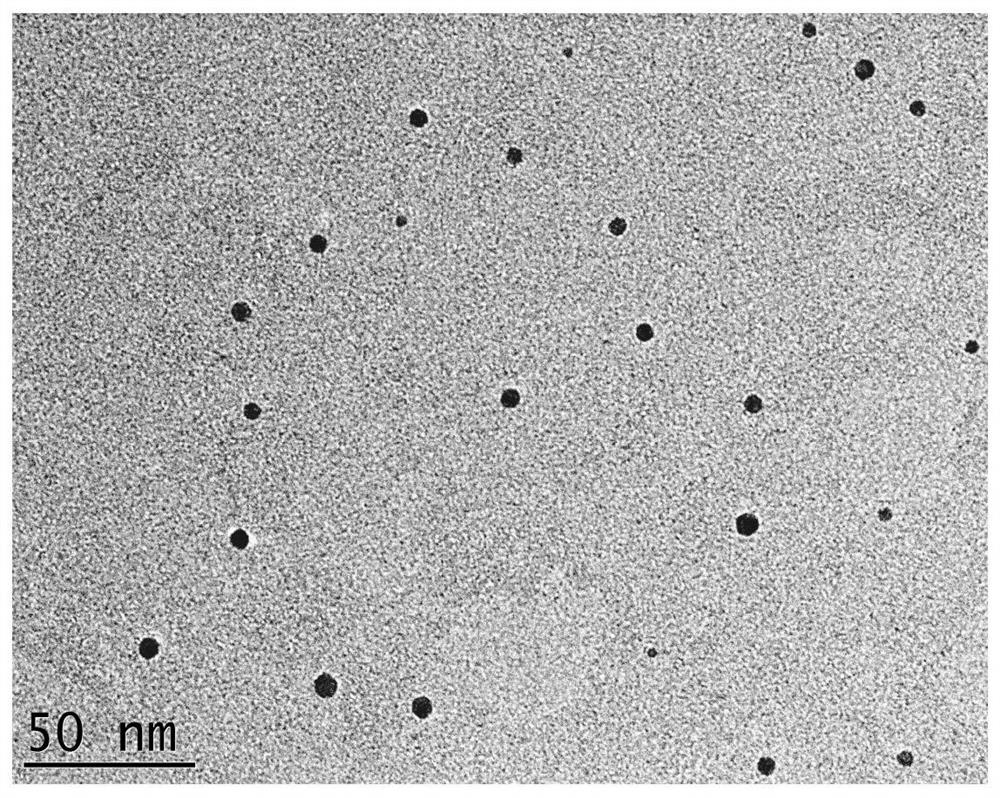

[0019] 2. The purification process of lignin-based carbon nanozyme: put the mixture in the cooled reaction kettle in a centrifuge, set the rotation speed to 6000rpm, and the time is 10min. After centrifugation, pass the obtained supernatant through a 0.22μm m...

Embodiment 2

[0021] This embodiment is a detection process of enzyme-like catalytic activity of lignin-based carbon nanozyme, which is specifically completed according to the following steps:

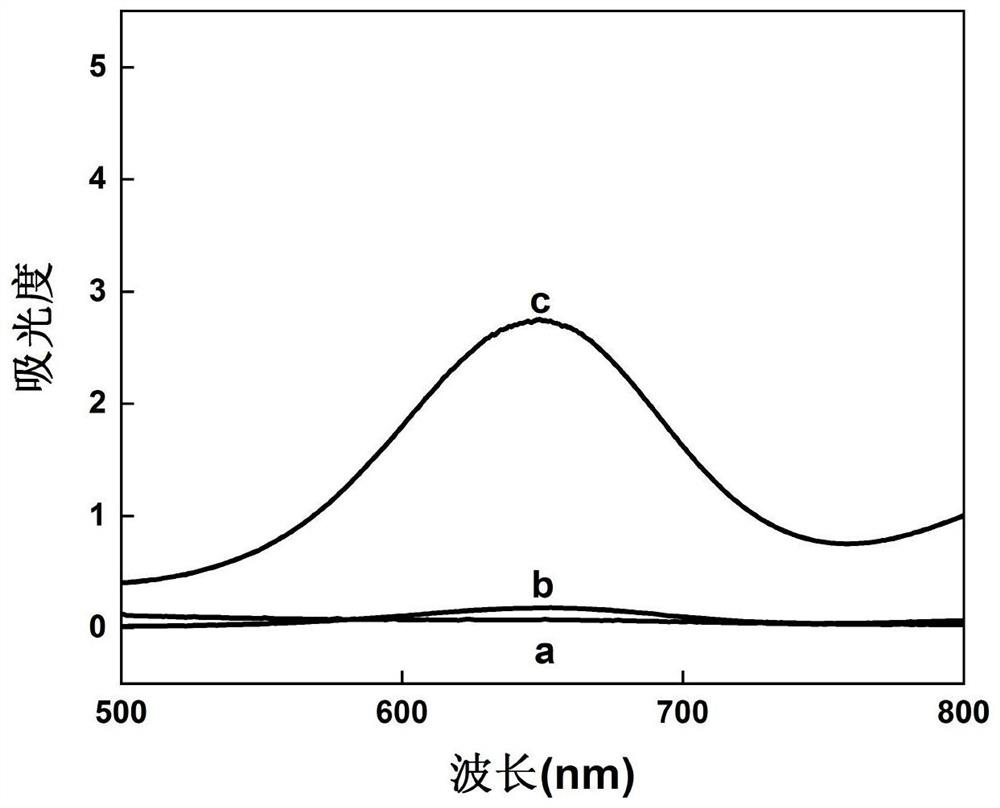

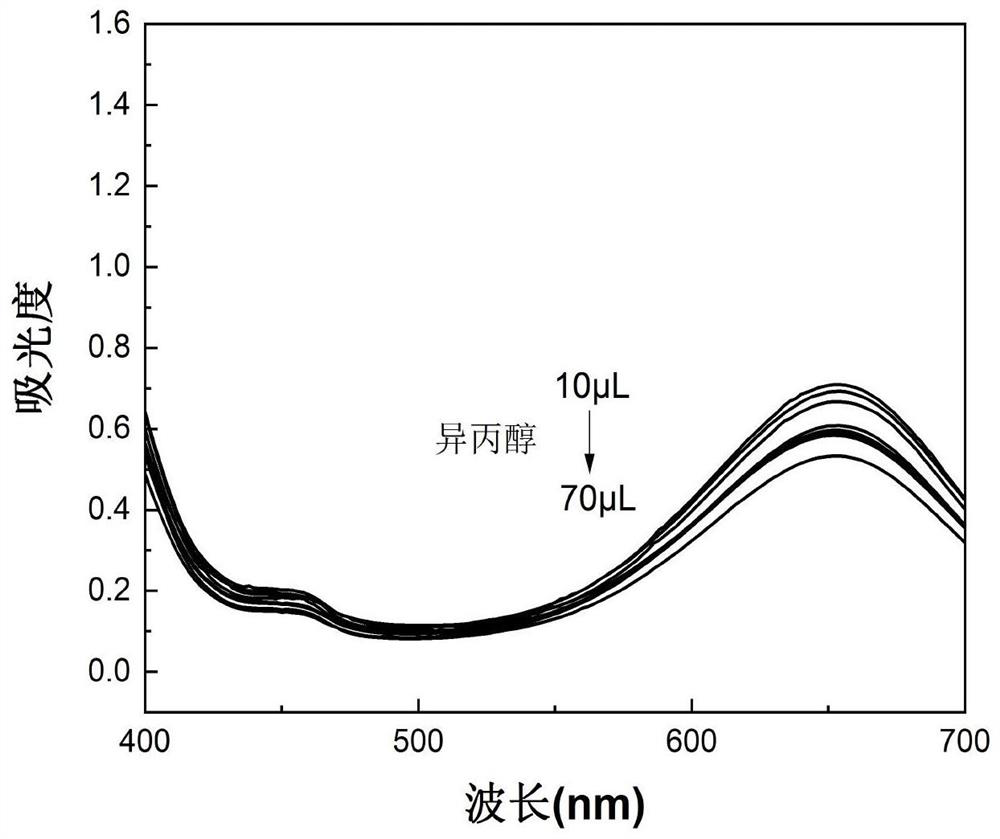

[0022]Set up a system of 50 μL 3 mg / mL lignin-based carbon nanozyme aqueous solution, 50 μL 5 mmol / L hydrogen peroxide solution, and 50 μL 10 mmol / L 3`3`5`5`-tetramethylbenzidine solution and use pH=4 acetic acid -Sodium acetate buffer (0.1mol / L) to dilute the system by 2mL; set up the following two control groups at the same time: 50μL of 5mmol / L hydrogen peroxide was mixed with acetic acid-sodium acetate buffer (0.1mol / L) of pH=4 Solution, 50μL 10mmol / L 3`3`5`5`-tetramethylbenzidine solution diluted to 2mL system and 50μL 3mg / mL lignin-based carbon nanozyme aqueous solution, 50μL 10mmol / L 3`3`5`5`-tetramethylbenzidine solution diluted to 2mL system. After incubating the above three groups of solutions in the dark at room temperature for 10 minutes, the absorbance spectra of the solutions were rec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com