Hand pushing type layered cutting recycling machine for asphalt concrete pavement

A kind of technology of asphalt concrete and recycling machine, which is applied in the direction of road, road, road repair, etc. It can solve the problems that the lower layer cannot be milled in place at one time, can not be adjusted to any depth, and the milling rotor has limited milling depth. The effect of adjustment, simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

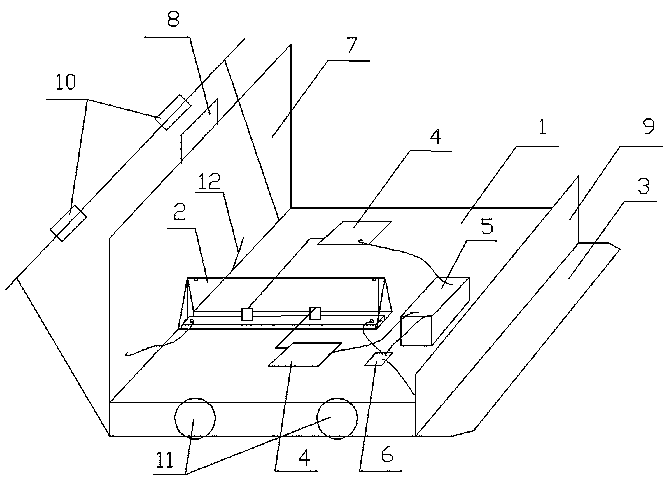

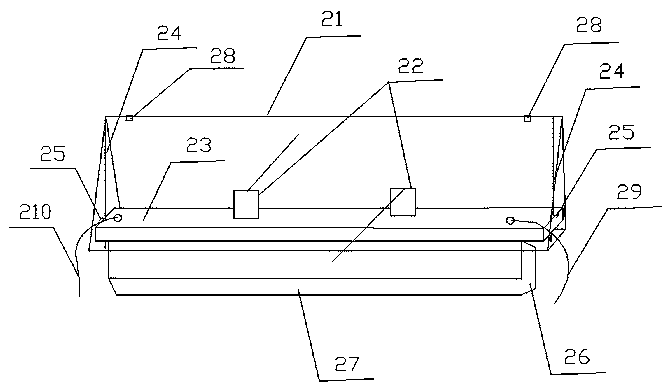

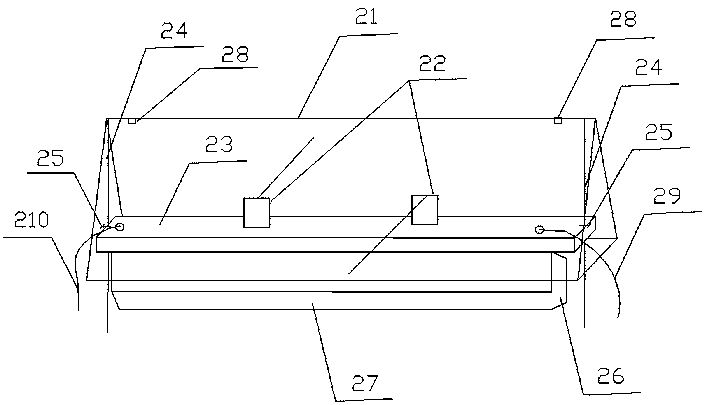

[0029] Specific implementation methods: such as figure 1 As shown, the profile of the hand-push type old asphalt concrete pavement layered cutting and recycling machine is just like a dolly, and the power switch is turned on by the liquid crystal display 8, and then the heating key of the kerf temperature display key 82 is pressed, if it is For the upper layer, only one heating tube needs to be heated. If it is the middle surface layer, two heating tubes can be heated. If it is the lower layer, three heating tubes can be heated. Stop heating when the temperature is close to the construction temperature of each surface layer. , let go of the foot support 12, you can walk forward through the four wheels 11, push the machine to the place where the longitudinal seam needs to be cut, unscrew the latch 25 on the combined structure 2 of the slitting knife, and make the slitting knife along the hanging The rod 24 falls to the road surface, and then presses the force display key 83 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com