Minitype solid rocket engine structure based on 3D printing technology

A solid rocket and 3D printing technology, applied in the direction of rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of small nozzle size, difficult installation, poor aerodynamic characteristics, etc., to achieve stable aerodynamic parameters, short process cycle, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] This embodiment is a miniature solid rocket motor structure based on 3D printing technology.

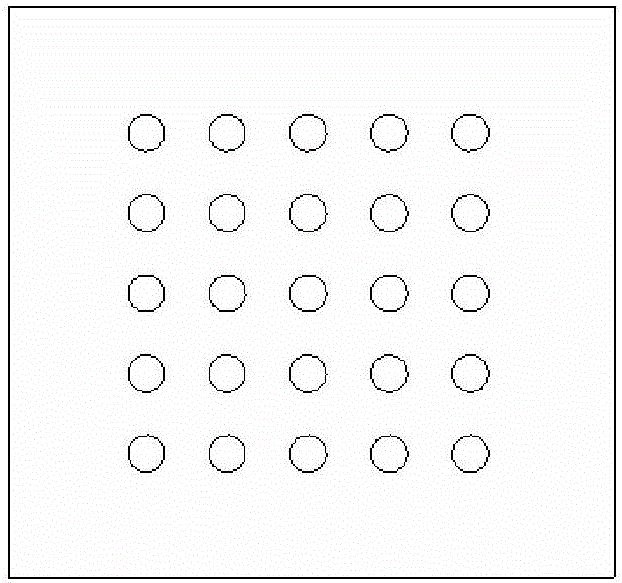

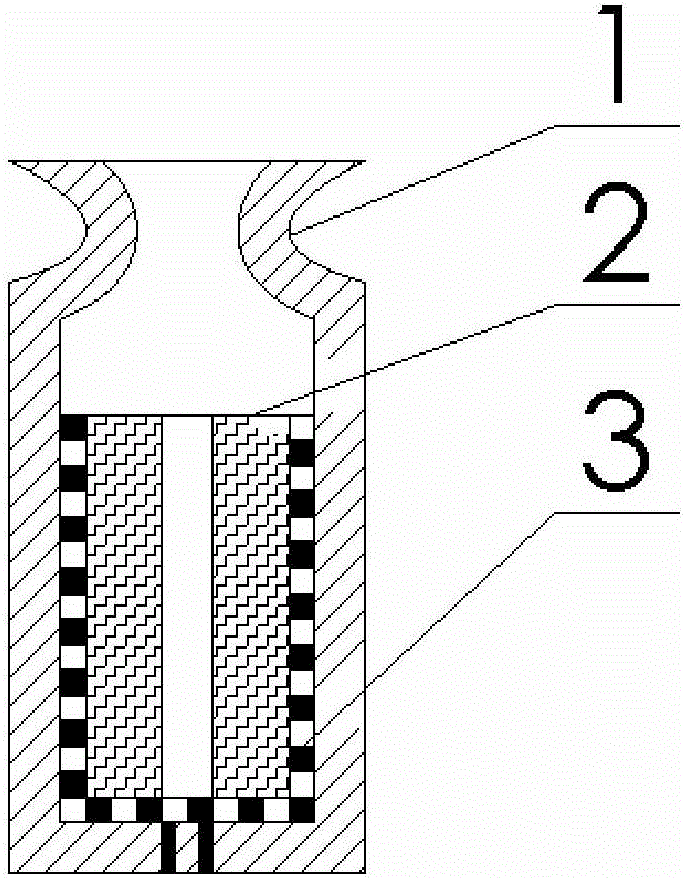

[0029] Different from the traditional micro-engine front head, combustion chamber, nozzle and powder column, which are processed separately and then assembled, all the parts in this embodiment are printed together, which is an airtight entity. According to the different materials used, the structure of the miniature solid rocket motor designed in this embodiment consists of three parts: the casing 1, the metal igniter 3 and the grain 2. The casing 1 includes a combustion chamber, a nozzle, and a front head, all of which are made of silicon material; the nozzle has a converging section and an expanding section; the metal igniter 3 is made of a copper conductor metal material; the powder column 2 is any solid The propellant; the casing 1, the metal igniter 3 and the powder column 2 form an integral structure.

[0030] The working principle of the miniature solid rocket motor: t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com