Rotary engine

A rotary engine, engine technology, applied in rotary piston engines, engine components, combustion engines, etc., can solve the problems of low heat loss, high fuel consumption rate, impossible to achieve complete combustion, and minimize noise and pressure leakage , The effect of minimizing vehicle exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, a rotary engine according to a preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings.

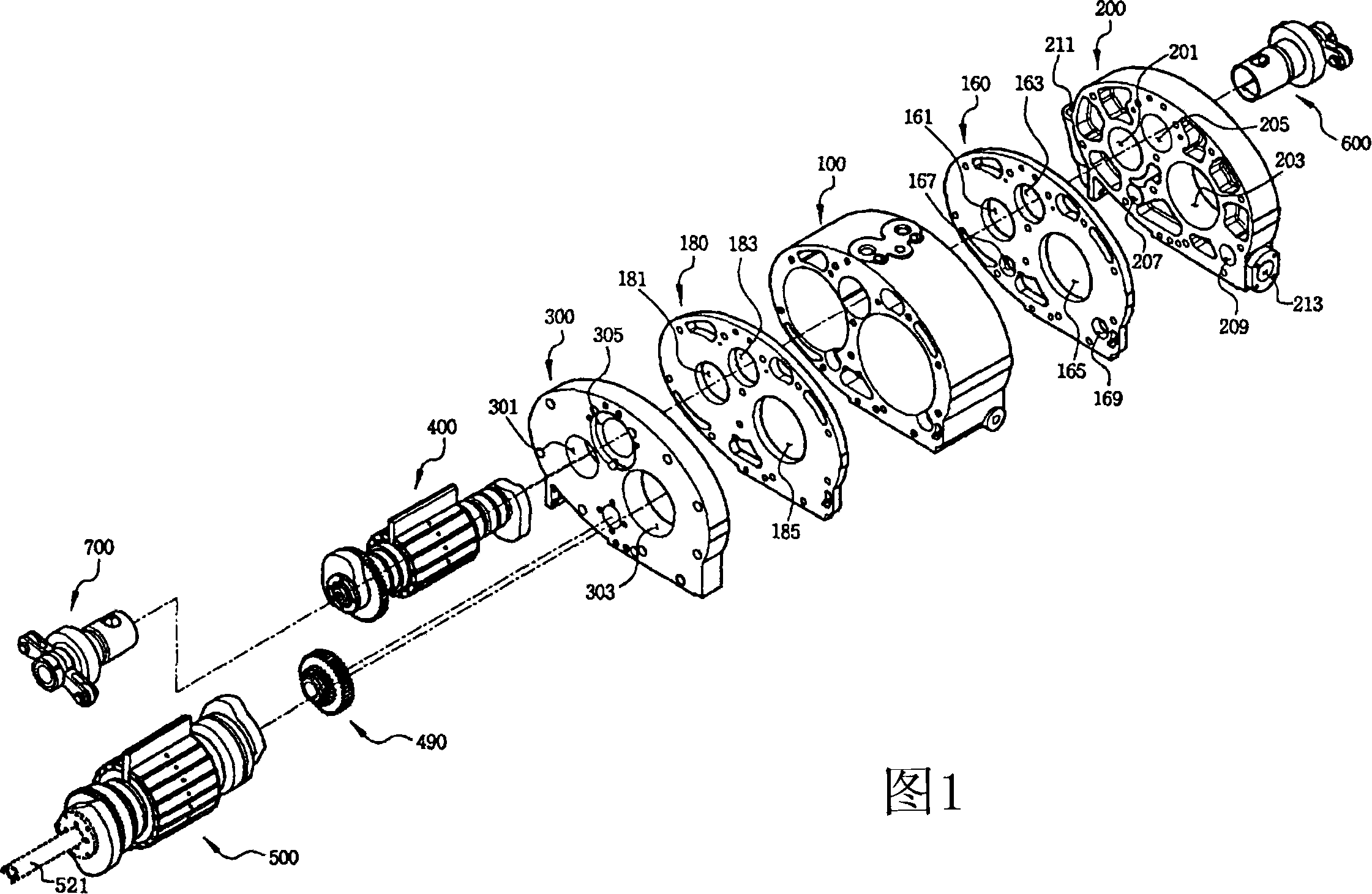

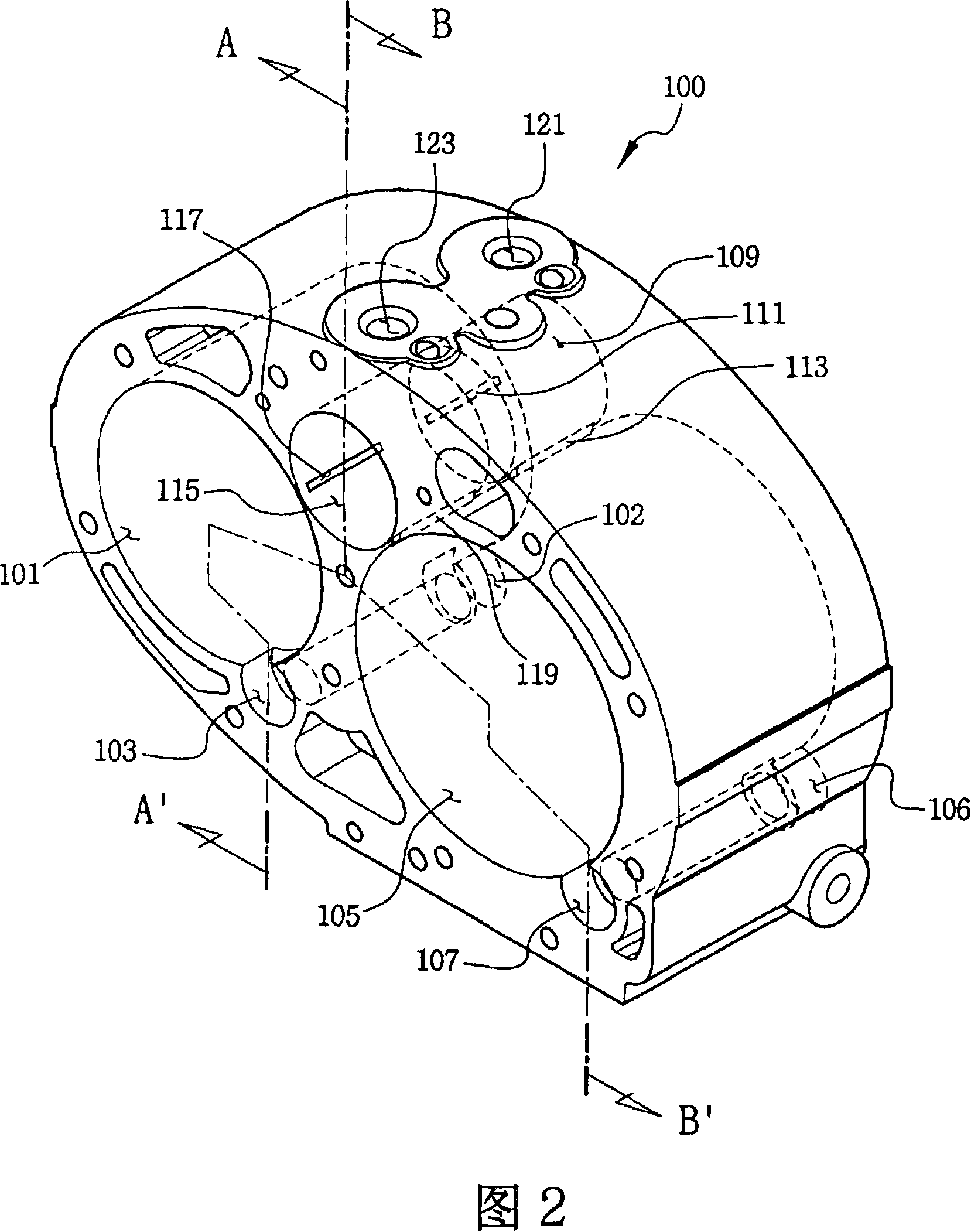

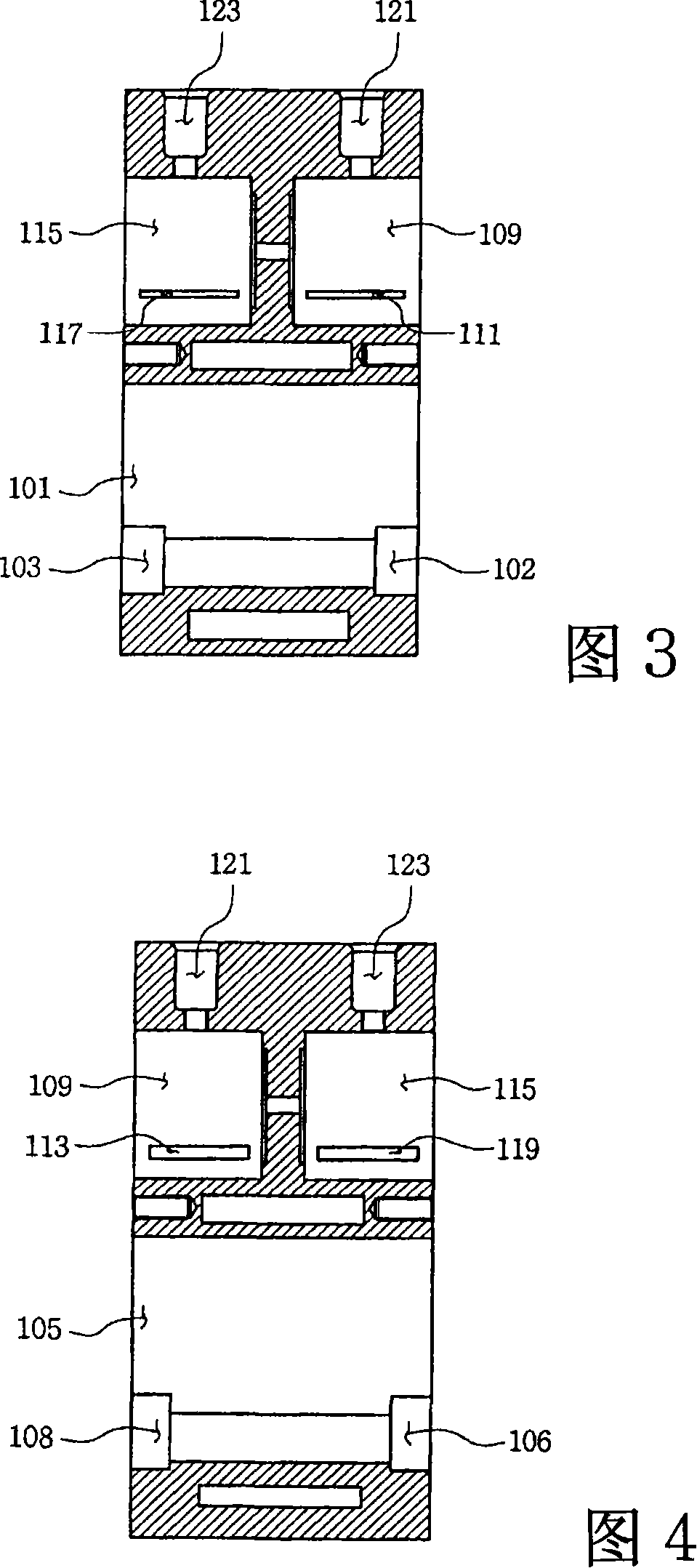

[0030]FIG. 1 is an exploded perspective view of a rotary engine according to an embodiment of the present invention. Fig. 2 is a perspective view of the engine body 100 of the rotary engine according to the present invention. Fig. 3 is a sectional view taken along line A-A' in Fig. 2 . Fig. 4 is a sectional view taken along line B-B' in Fig. 2 . FIG. 5 is a perspective view showing a compression rotor 400 of a rotary engine according to the present invention. FIG. 6 is a perspective view showing an output rotor 500 of the rotary engine according to the present invention. FIG. 7 is a perspective view showing a valve 600 of a rotary engine according to the present invention. Fig. 8 is a front view showing a valve 600 of the rotary engine according to the present invention. FIG. 9 is a partially cutaway pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com