Rotation burning type burning device

A technology of incineration device and incinerator, which is applied in the direction of combustion method, combustion type, incinerator, etc., and can solve problems such as inability to obtain efficient incineration treatment and environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

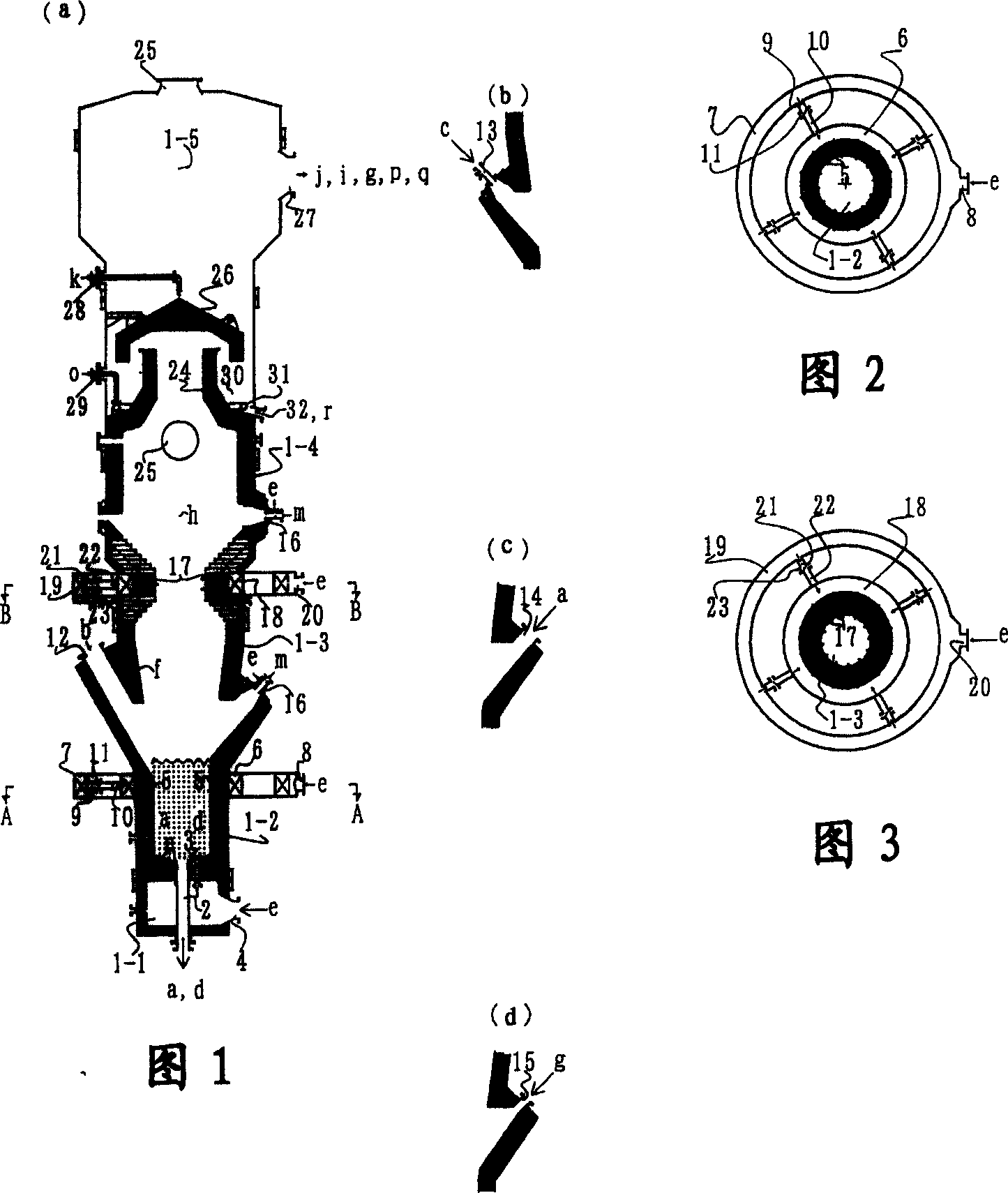

[0030] Hereinafter, embodiments of the present invention will be described in detail based on the accompanying drawings. Fig. 1 is a cross-sectional view (a) conceptually showing the incineration device of the present invention, which is divided into the following parts: a wind box 1-1, which is a hot air storage part for flowing a heat medium a such as silica sand, and a filling heat medium a. The fluidized layer chamber 1-2 where the medium a flows, the first layer of rotating combustion chamber 1-3, the second layer of rotating combustion chamber 1-4, and the circulating water wetted wall gas cooling chamber 1-5.

[0031] Above-mentioned bellows 1-1 is provided with cylindrical heat medium take-out outlet 2 passing through the bottom along the central axis, and hot blast air supply pipe 4 positioned at the side of bellows 1-1. Outside the furnace, an air heat exchanger (Fig. Omit) The pressurized air e for heat exchange is delivered to the bellows 1-1.

[0032] The fluidiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com