Biogasoline

A technology of bio-gasoline and bio-oil, applied in the direction of biological raw materials, processing hydrocarbon oil, petroleum industry, etc., can solve global forest destruction and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

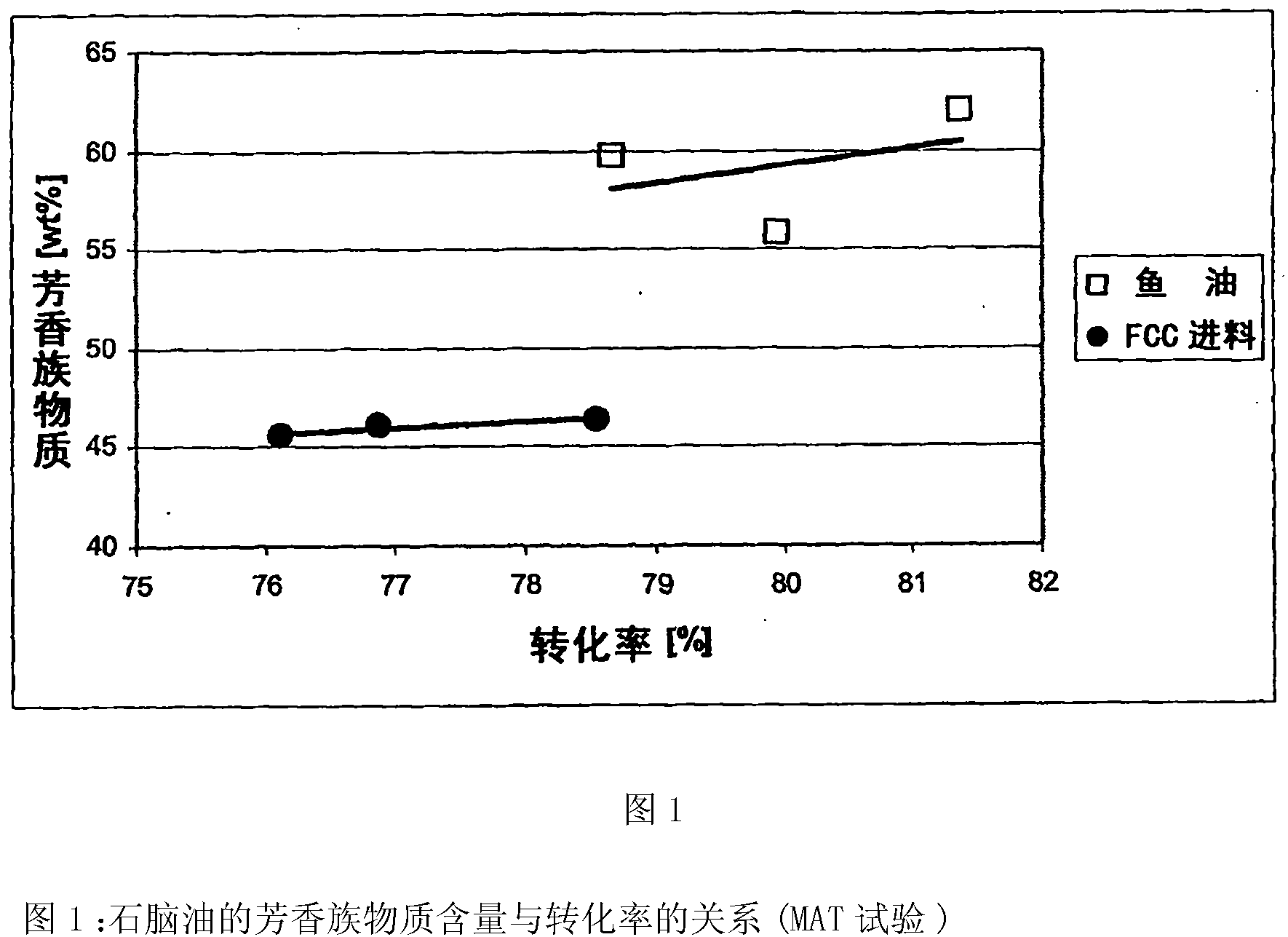

[0068] Example 1: Catalytic cracking of fish oil in MAT

[0069] Demonstration of cracking of fish oil in a micro-reactivity test (MAT) reactor. The MAT test is a method well known in the catalytic cracking art.

[0070] fish oil from norway Scanbio obtained, is equivalent to so-called crude fish oil, ie fish oil that has not been refined. Some properties of this fish oil are shown in Table 1:

[0071] Table 1: Properties of Crude Fish Oil

[0072] Density, kg / l

[0073] In the MAT trial, two different feeds were tested and compared

[0074] · FCC feed without added fish oil (atmospheric residue)

[0075] · Fish oil without added FCC feed

[0076] The FCC feed used in this test was a North Sea atmospheric residue with the following properties

[0077] Table 2: Properties of Atmospheric Residues

[0078] Density 09275kg / l

[0079] Conradson residual carbon content 3.0wt%

[0080] Sulfur 0.404wt%

[0081] Ni 1.6ppm

[0082] V 2.0ppm

[0083] Na 0.6ppm

[0...

Embodiment 2

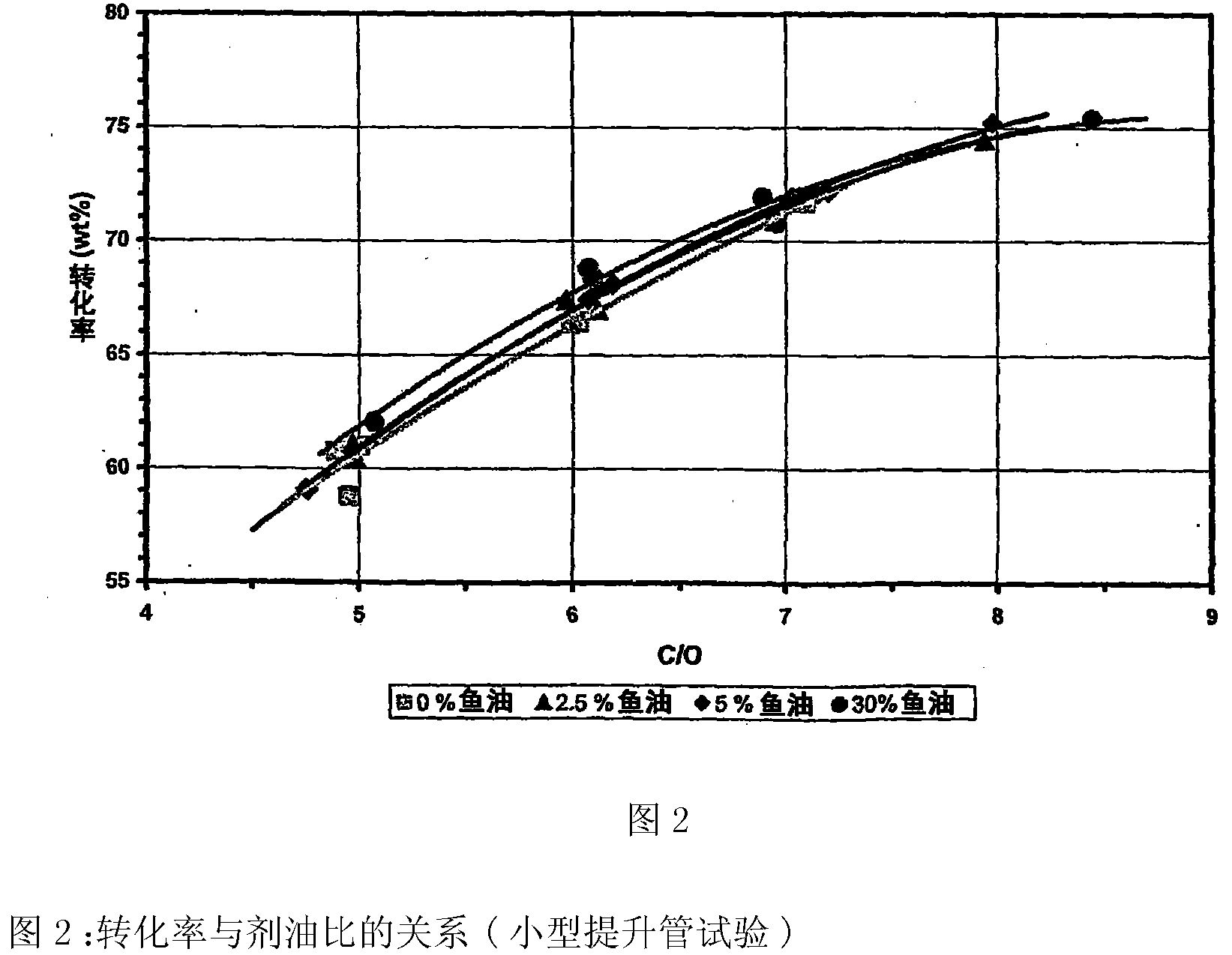

[0095] Example 2 Catalytic cracking of fish oil and atmospheric residue mixture in small riser

[0096] In a continuously operating FCC mini riser, different mixtures of the two feeds described in Example 1 (fish oil and North Sea atmospheric residue) were tested.

[0097] The FCC catalyst used in these tests was an equilibrium catalyst (ECAT) from an FCC unit processing North Sea atmospheric residue.

[0098] figure 2 The conversion is shown as a function of the agent-to-oil ratio for different mixtures consisting of fish oil and FCC feed. As shown in the figure, mixing fish oil into the FCC feed had no significant effect on conversion.

[0099] The interpolated yields tested are shown in Table 5 for comparison at the same conversion (72.5%).

[0100] Table 5: Yields (wt%) of different products and product fractions

[0101]

[0102] As done in Table 4, the results were used to estimate the yield structure when 5.1% fish oil was mixed into the FCC feed. These results...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com