Patents

Literature

38 results about "Biogasoline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biogasoline is gasoline produced from biomass such as algae. Like traditionally produced gasoline, it contains between 6 (hexane) and 12 (dodecane) carbon atoms per molecule and can be used in internal-combustion engines. Biogasoline is chemically different from biobutanol and bioethanol, as these are alcohols, not hydrocarbons.

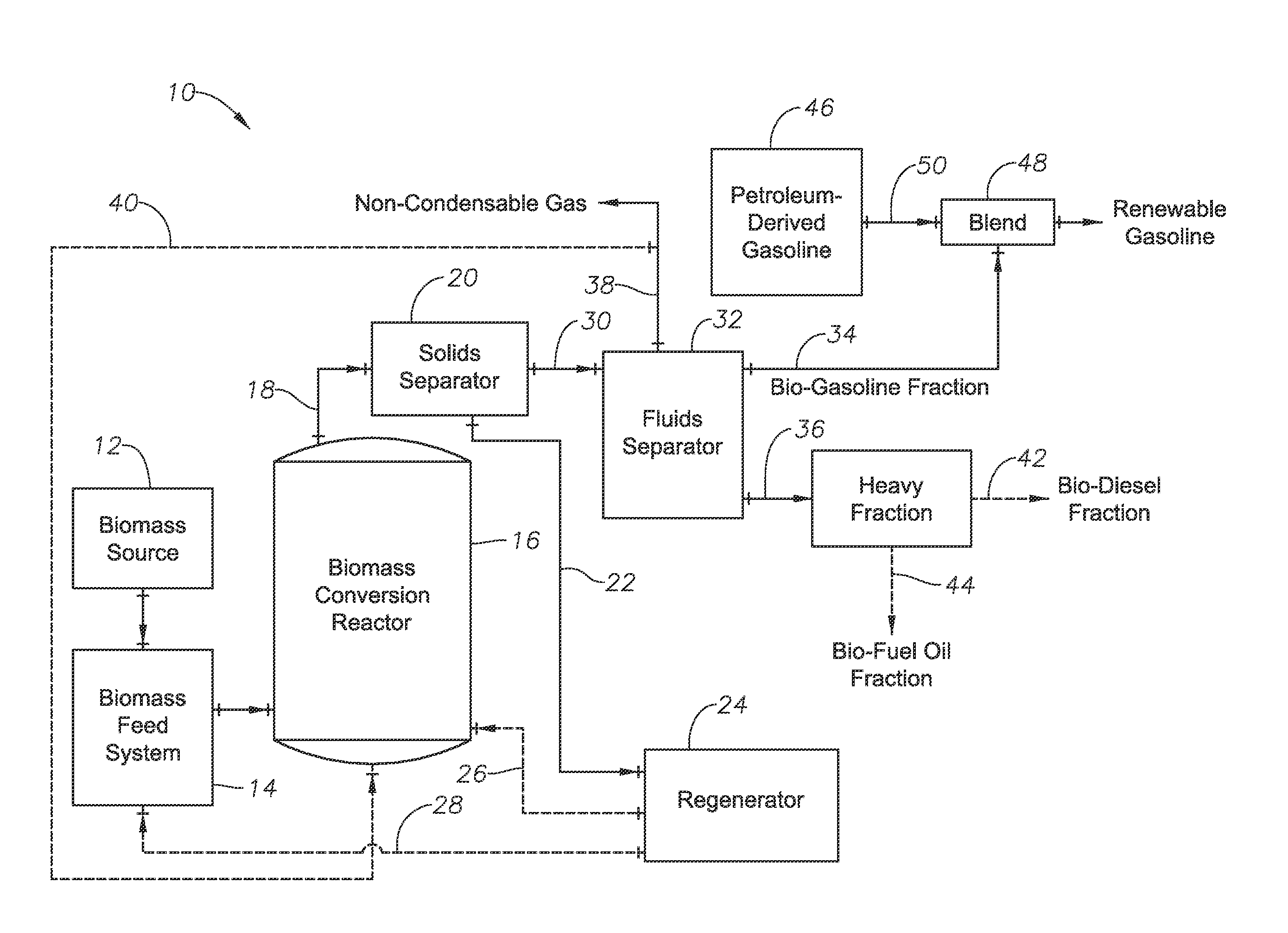

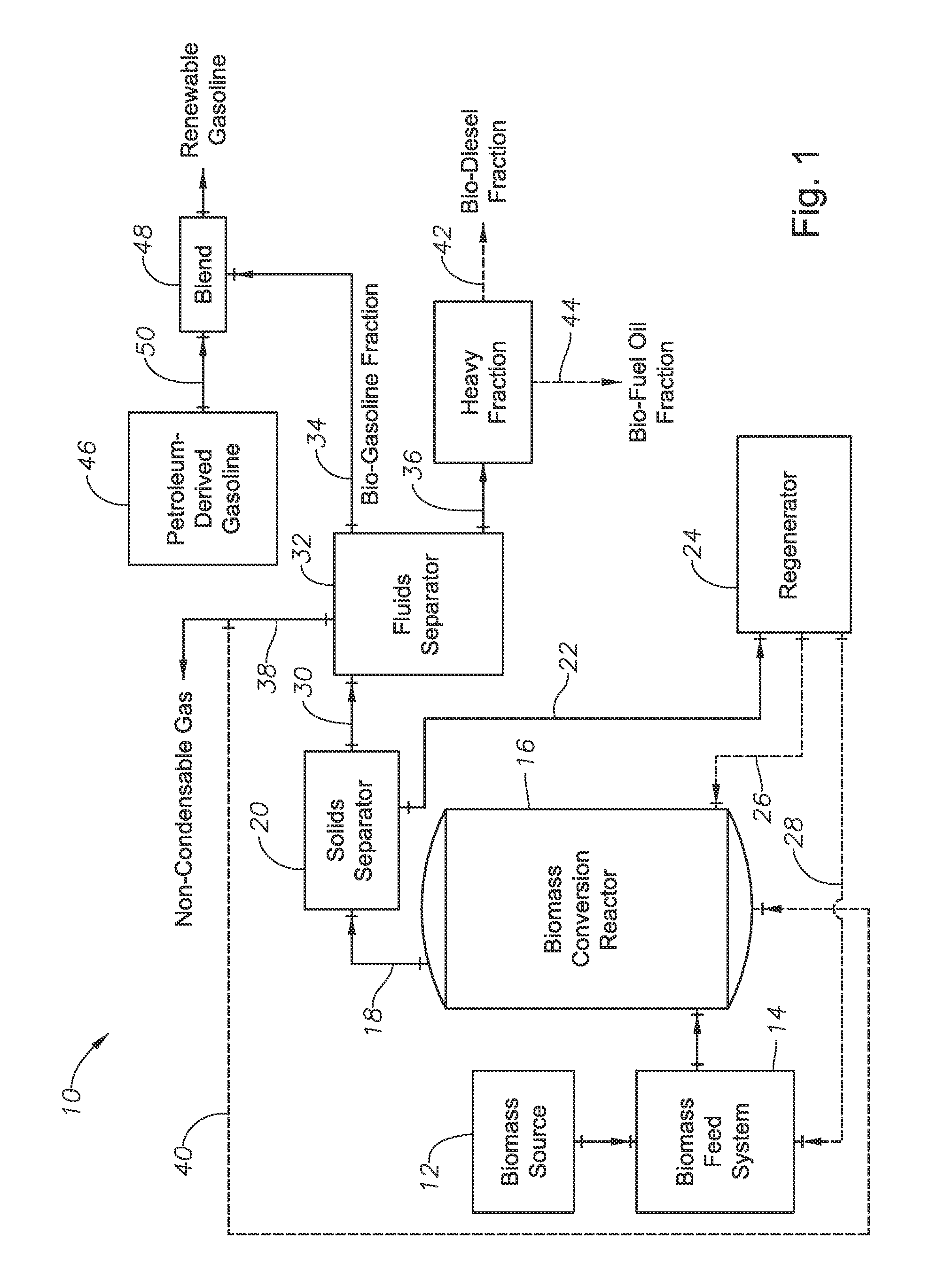

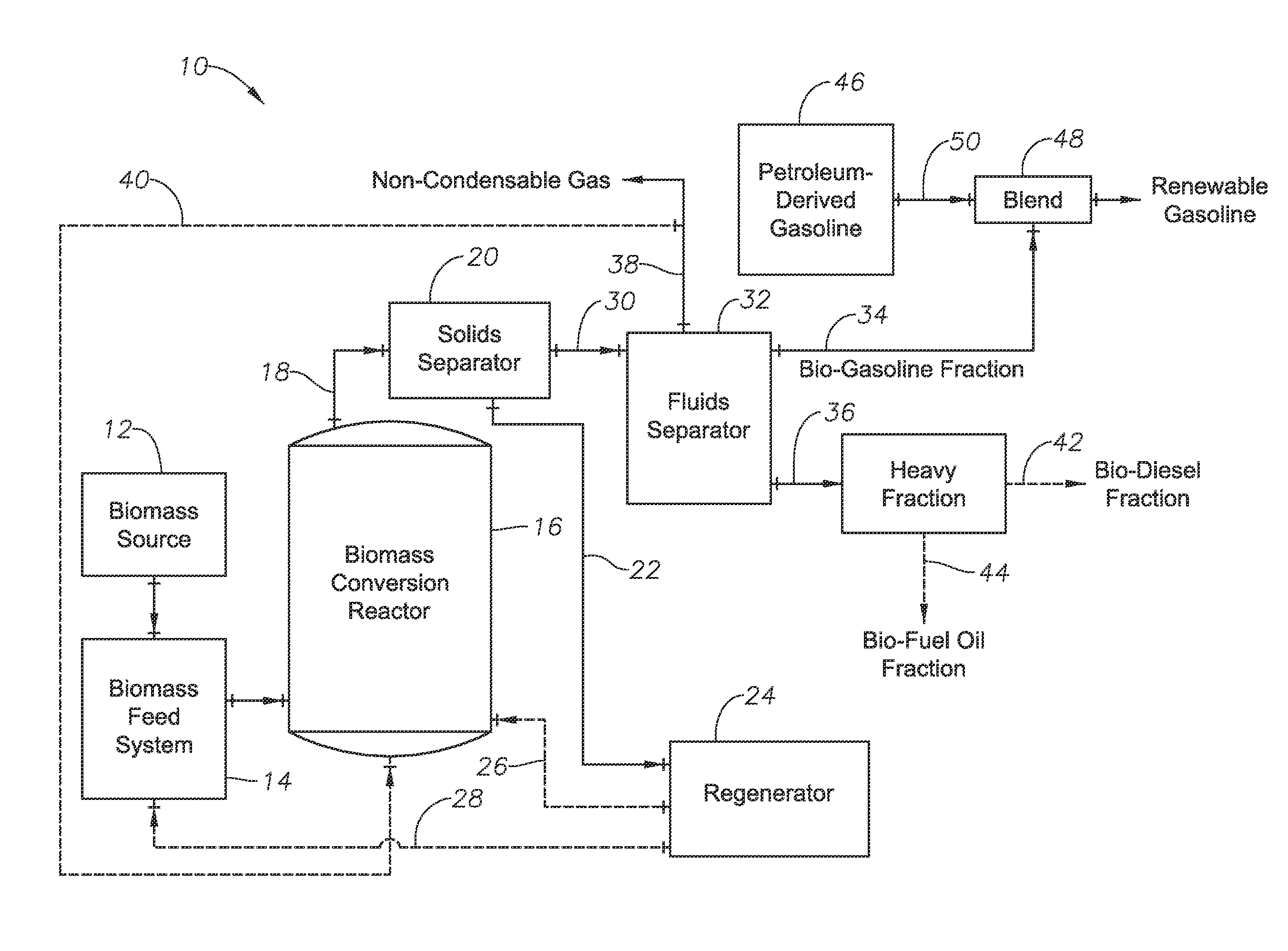

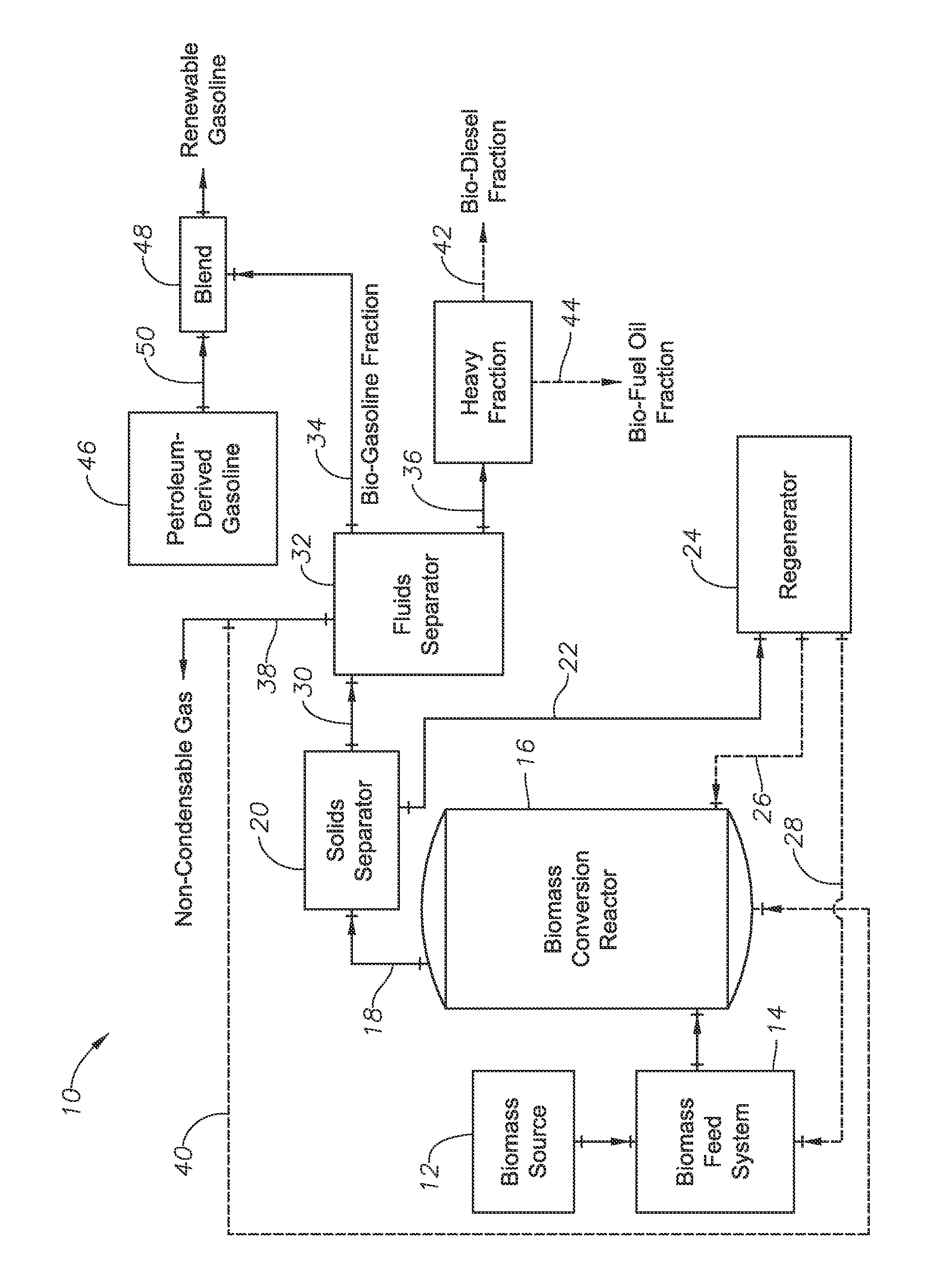

Production of renewable bio-gasoline

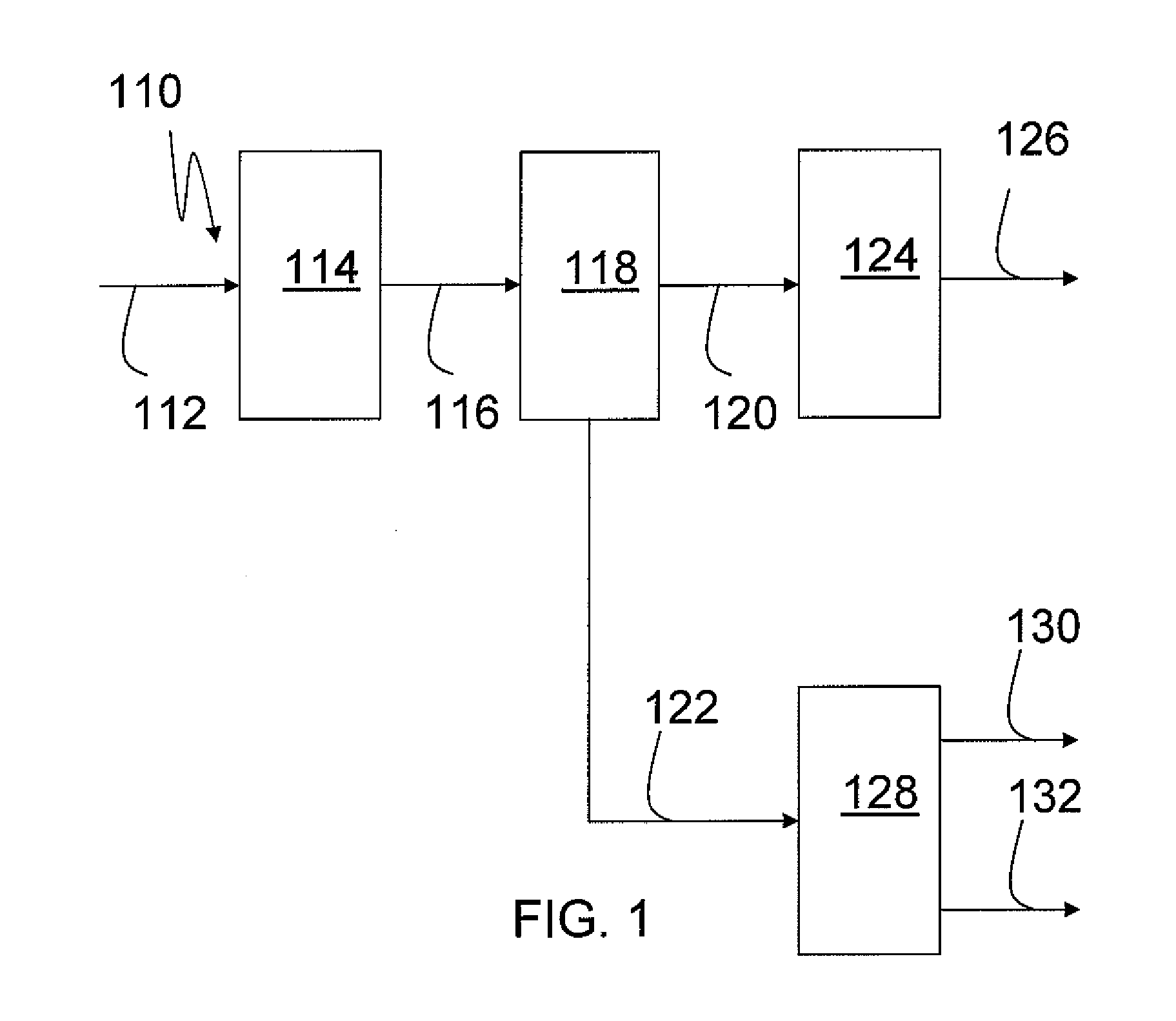

A process and system for separating bio-gasoline, bio-diesel and bio-fuel oil fractions from a bio-oil, and for producing a renewable gasoline including at least in part the bio-gasoline fraction, is provided. The process comprises separating bio-oil into a bio-gasoline fraction and a heavy fraction based on their boiling points. At least a portion of the bio-gasoline fraction is directly blended with a petroleum-derived gasoline, without any prior hydrotreatment, to thereby provide a renewable gasoline composition.

Owner:MARD INC

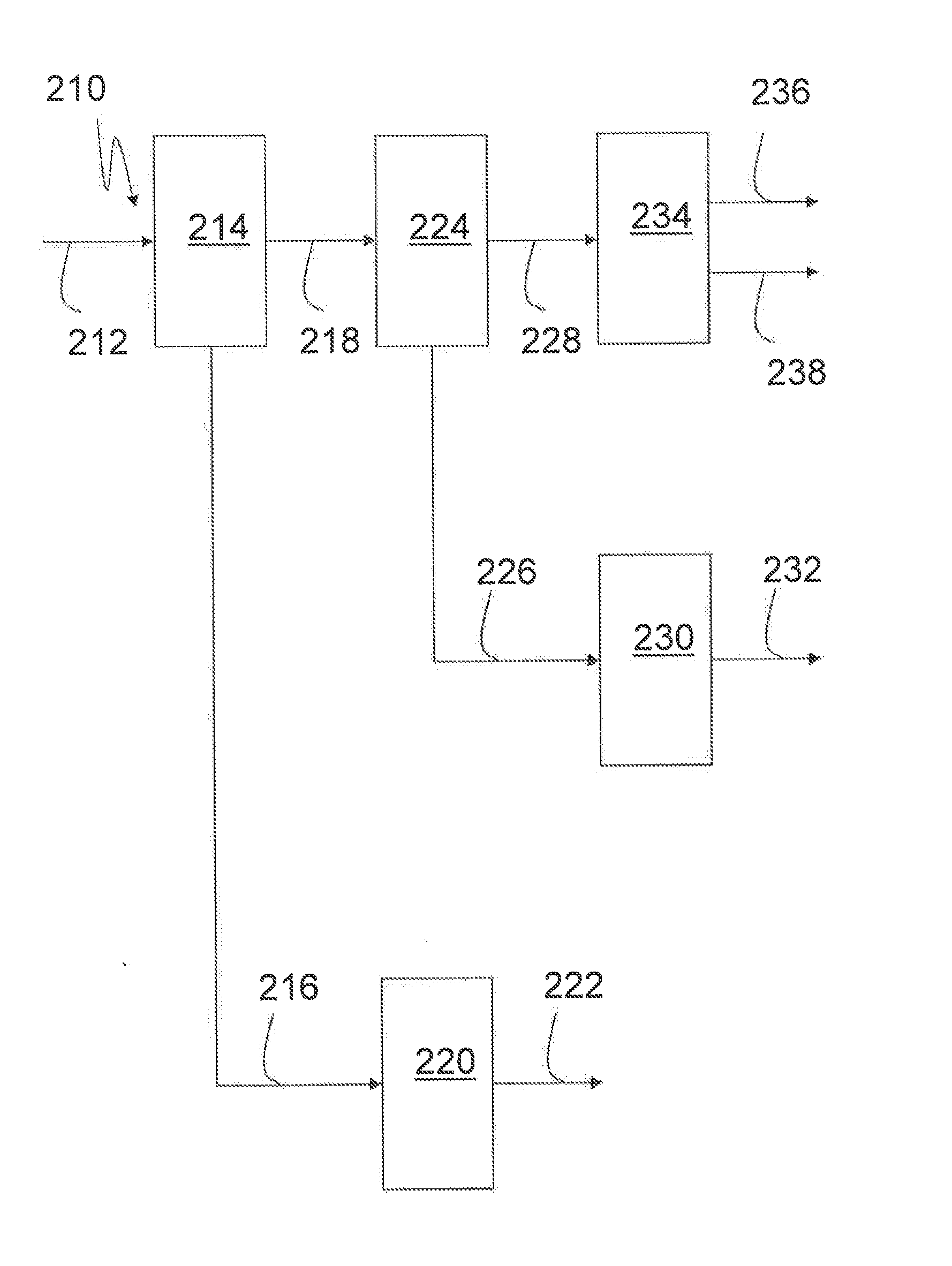

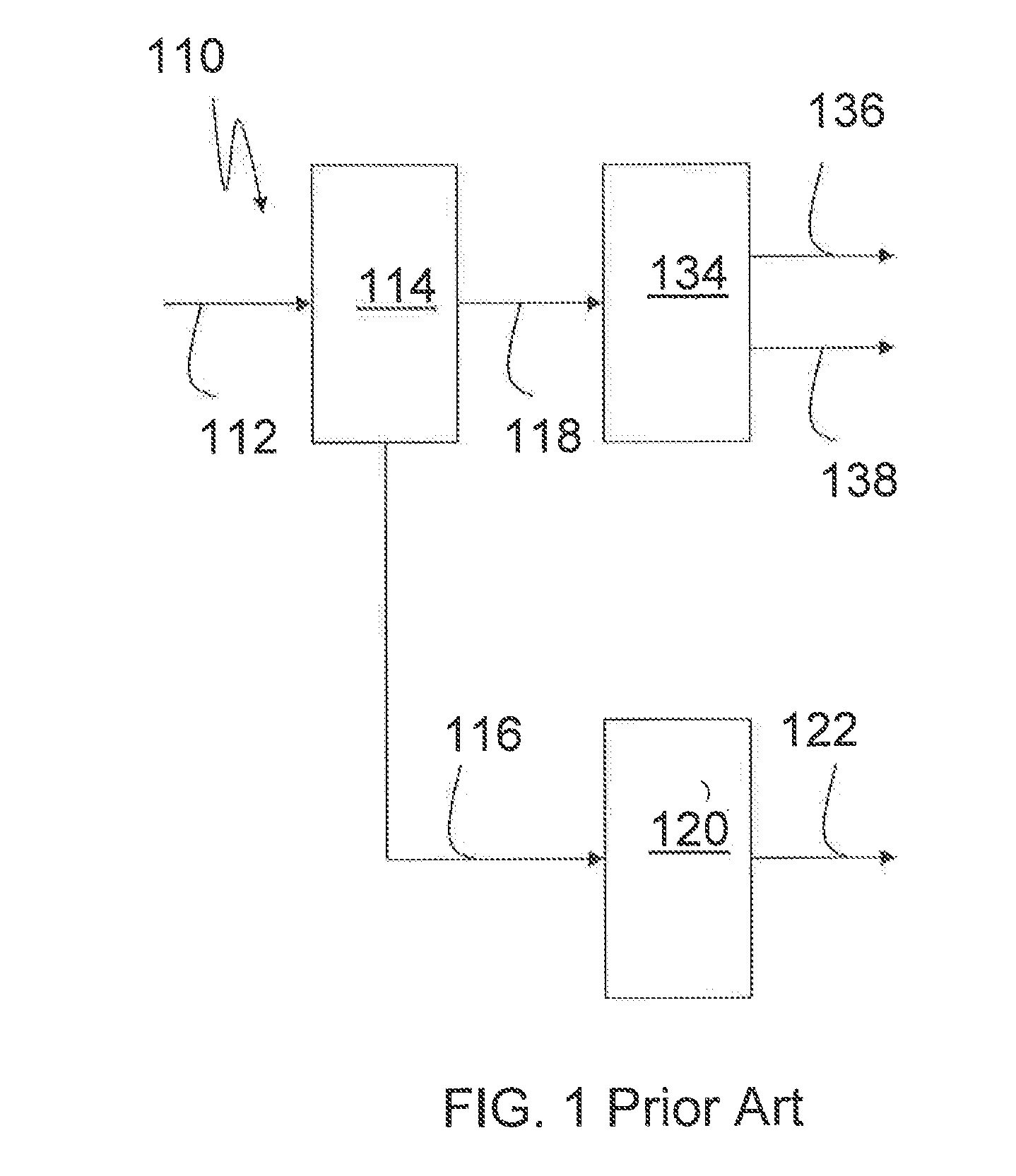

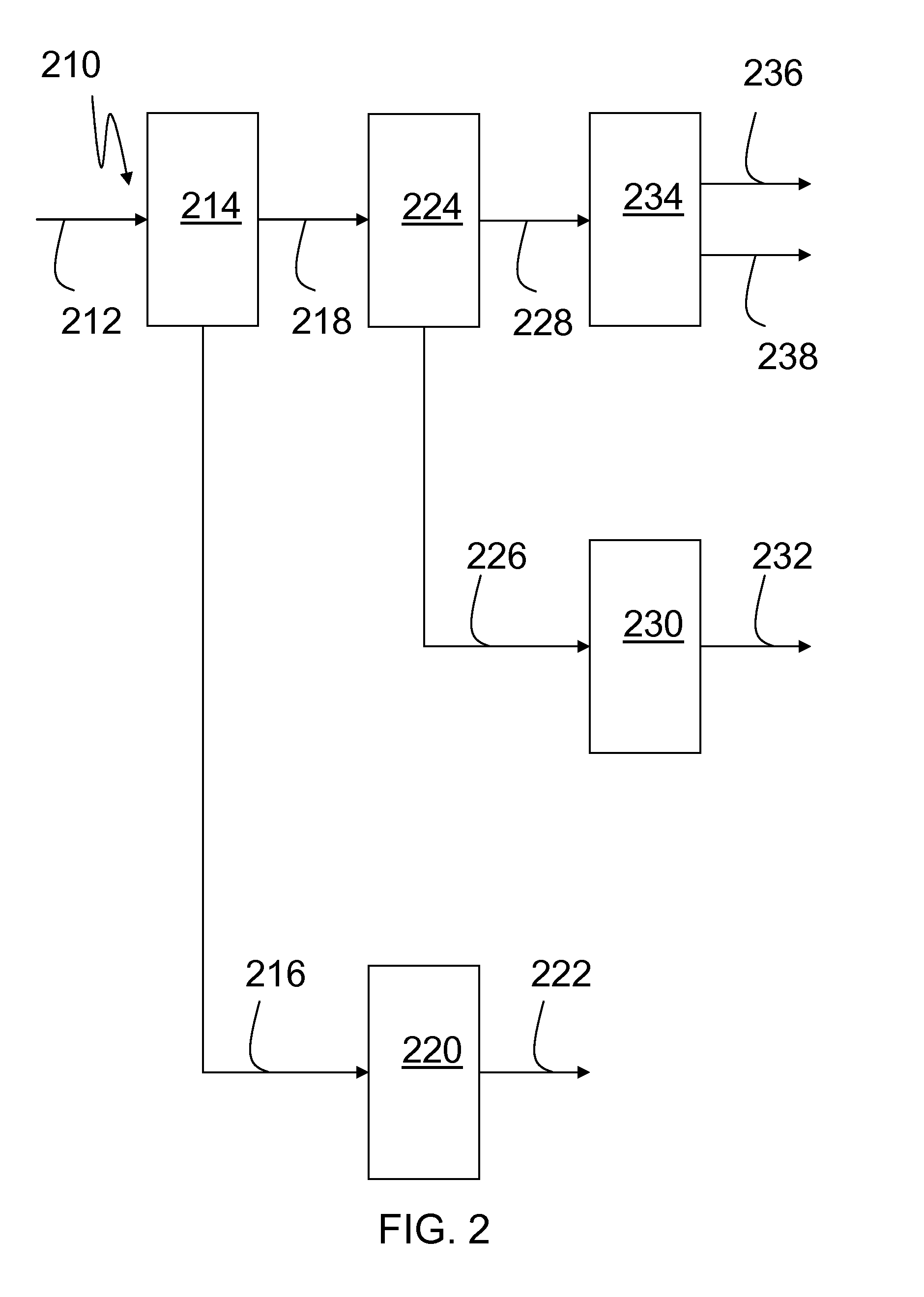

Process, Plant, and Biofuel For Integrated Biofuel Production

InactiveUS20110126448A1Bioreactor/fermenter combinationsBiological substance pretreatmentsCelluloseBiodiesel

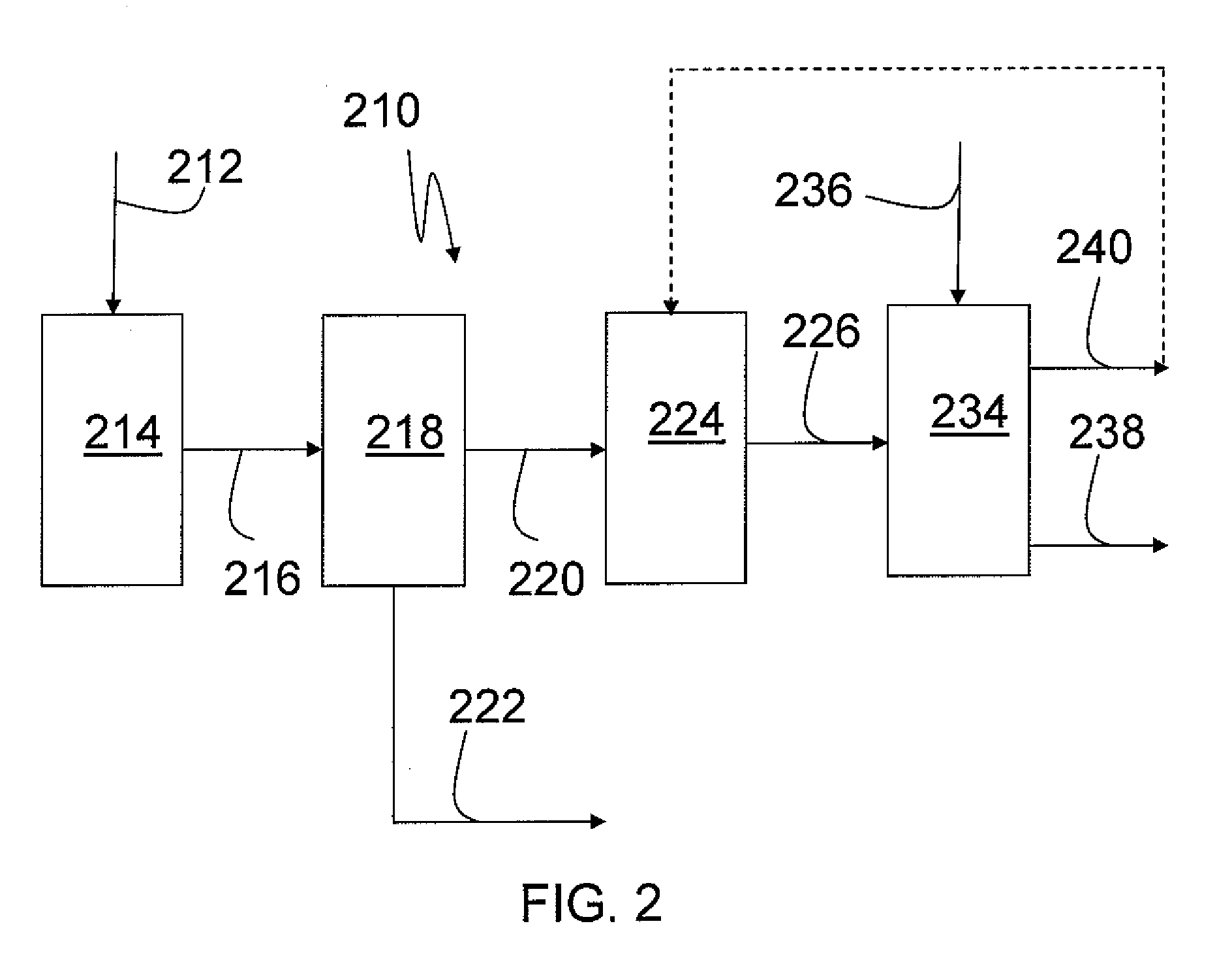

This invention relates to a process, a plant, and a biofuel for integrated biofuel production, such as with biogasoline, biodiesel, and / or sugar product. The integrated process includes the step of removing hexose from a feedstock to form a lignocellulosic material. The process also includes the step of converting the hexose to a biogasoline and / or a biodiesel material, and the step of depolymerizing lignocellulosic material to form pentose and a residue. The process also includes the step of converting the pentose to a biogasoline and / or a biodiesel material.

Owner:BP BIOFUELS UK

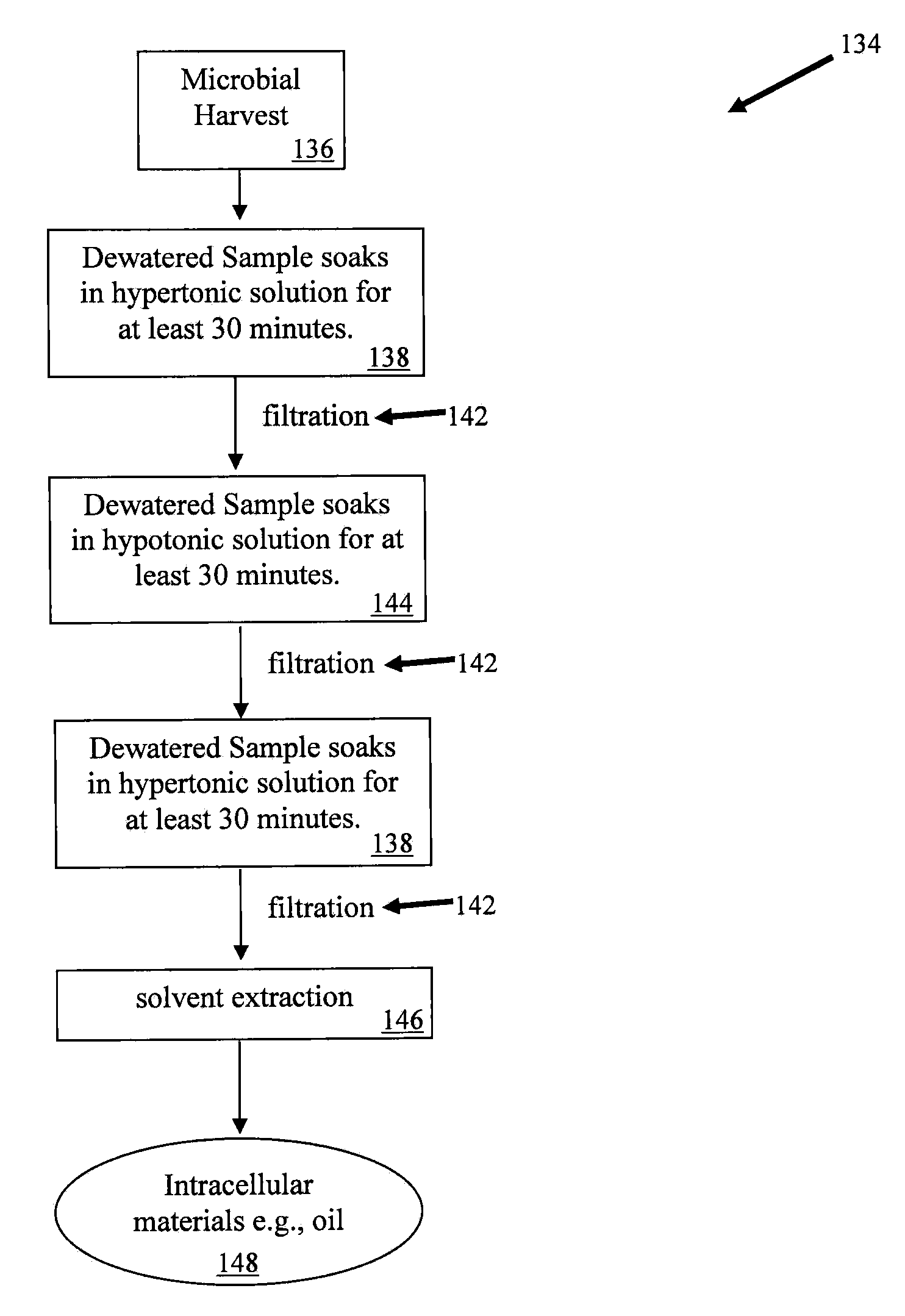

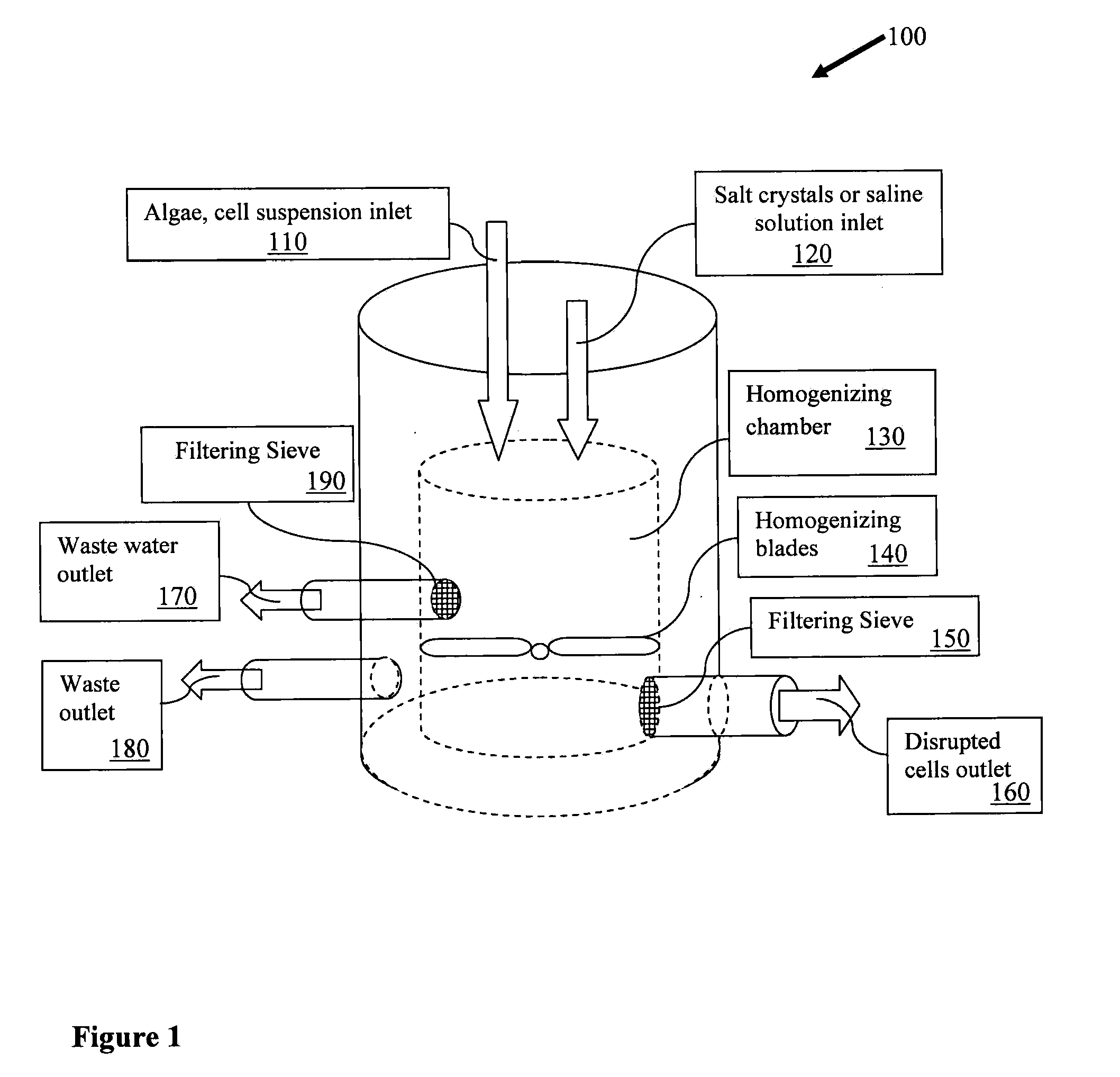

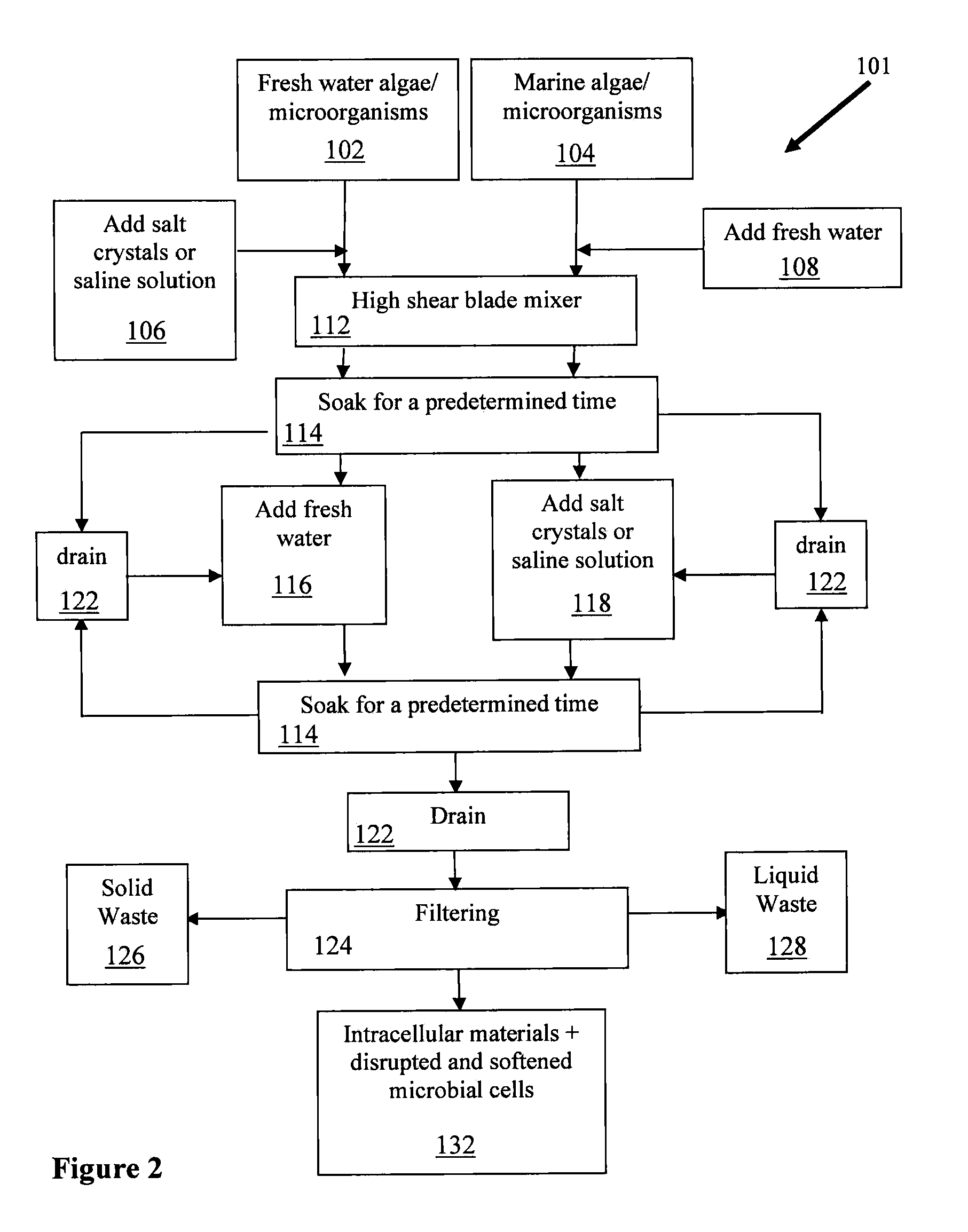

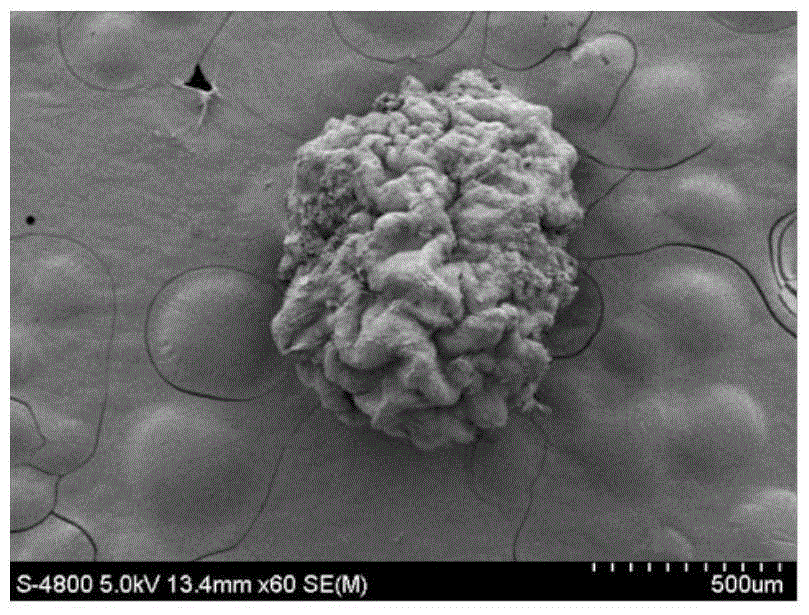

Apparatus and method for enhanced disruption and extraction of intracellular materials from microbial cells

Provided are surprisingly beneficial osmotic stress shock methods for facilitating disruption and / or extraction of microorganisms, comprising a synergistic combination of at least one hypotonic shock and at least two hypertonic shocks, wherein the last shock is a hypertonic shock. Preferred aspects of the invention relate to facilitating disruption of a broad spectrum of microorganisms (e.g., algae, bacteria, yeast, fungus, etc.). In particular aspects the microbial cells are subjected to: a hypertonic / hypotonic / hypertonic tertiary shock; a hypotonic / hypertonic / hypertonic tertiary shock; or a hypotonic / hypertonic / hypotonic / hypertonic quaternary shock. Particular aspects further comprise disrupting and / or extracting of the shocked microbial cells, and isolating a cellular constituent or bioproduct (e.g., biofuel, biocrude, bioenergy, biogas, biodiesel, bioethanol, biogasoline, pharmaceuticals, nutraceuticals, food, vitamins, feedstock, dyes, colorants, sulfur, fertilizer, bioplastic) therefrom. In particular preferred aspects, facilitation of algae disruption and / or extraction is provided and in certain embodiments, isolation of at least one of lipid, oil, and triacylglycerol is enhanced.

Owner:DHAMWICHUKORN SRISUDA

Process, plant and biofuel for integrated biofuel production

InactiveUS20100146842A1Bioreactor/fermenter combinationsBiological substance pretreatmentsCelluloseBiodiesel

This invention relates to a process, a plant, and a biofuel for integrated biofuel production, such as with biogasoline, biodiesel, and / or sugar product. The integrated process includes the step of removing hexose from a feedstock to form a lignocellulosic material. The process also includes the step of converting the hexose to a biogasoline and / or a biodiesel material, and the step of depolymerizing lignocellulosic material to form pentose and a residue. The process also includes the step of converting the pentose to a biogasoline and / or a biodiesel material.

Owner:BP BIOFUELS UK

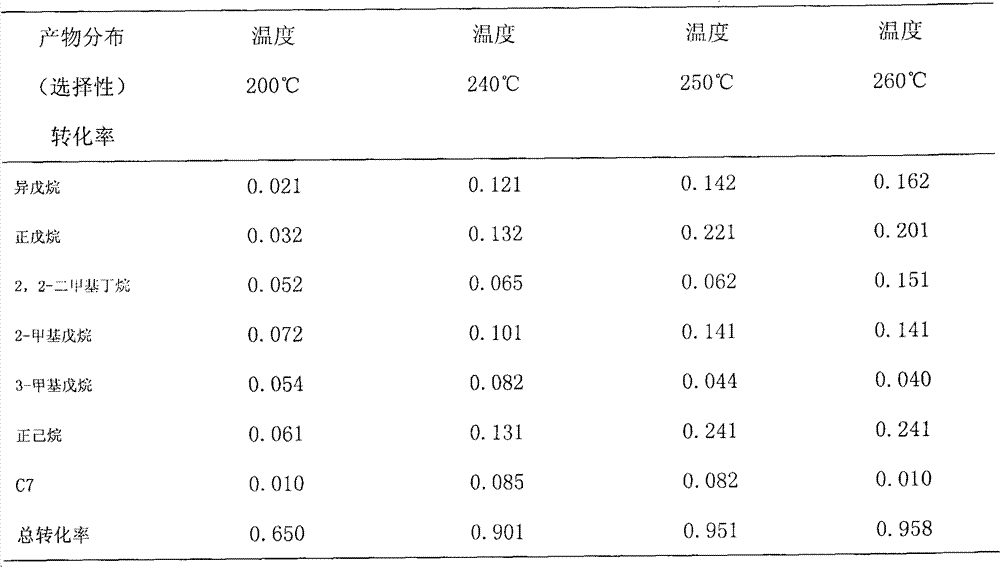

Method of catalyzing sorbitol to synthesize bio-petrol

ActiveCN101550350AIncrease contentIncrease total octaneMolecular sieve catalystsLiquid hydrocarbon mixture productionAlkaneSlurry

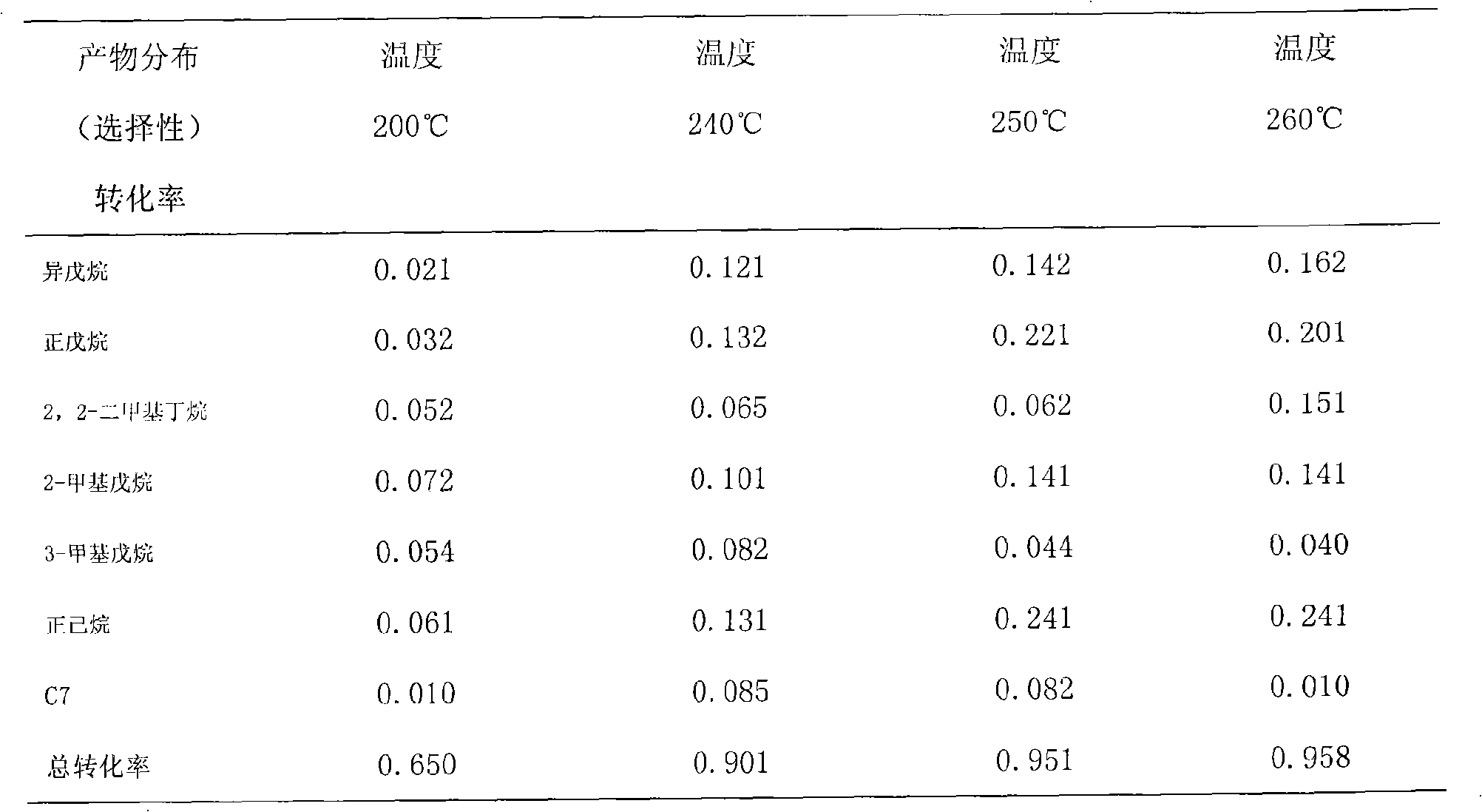

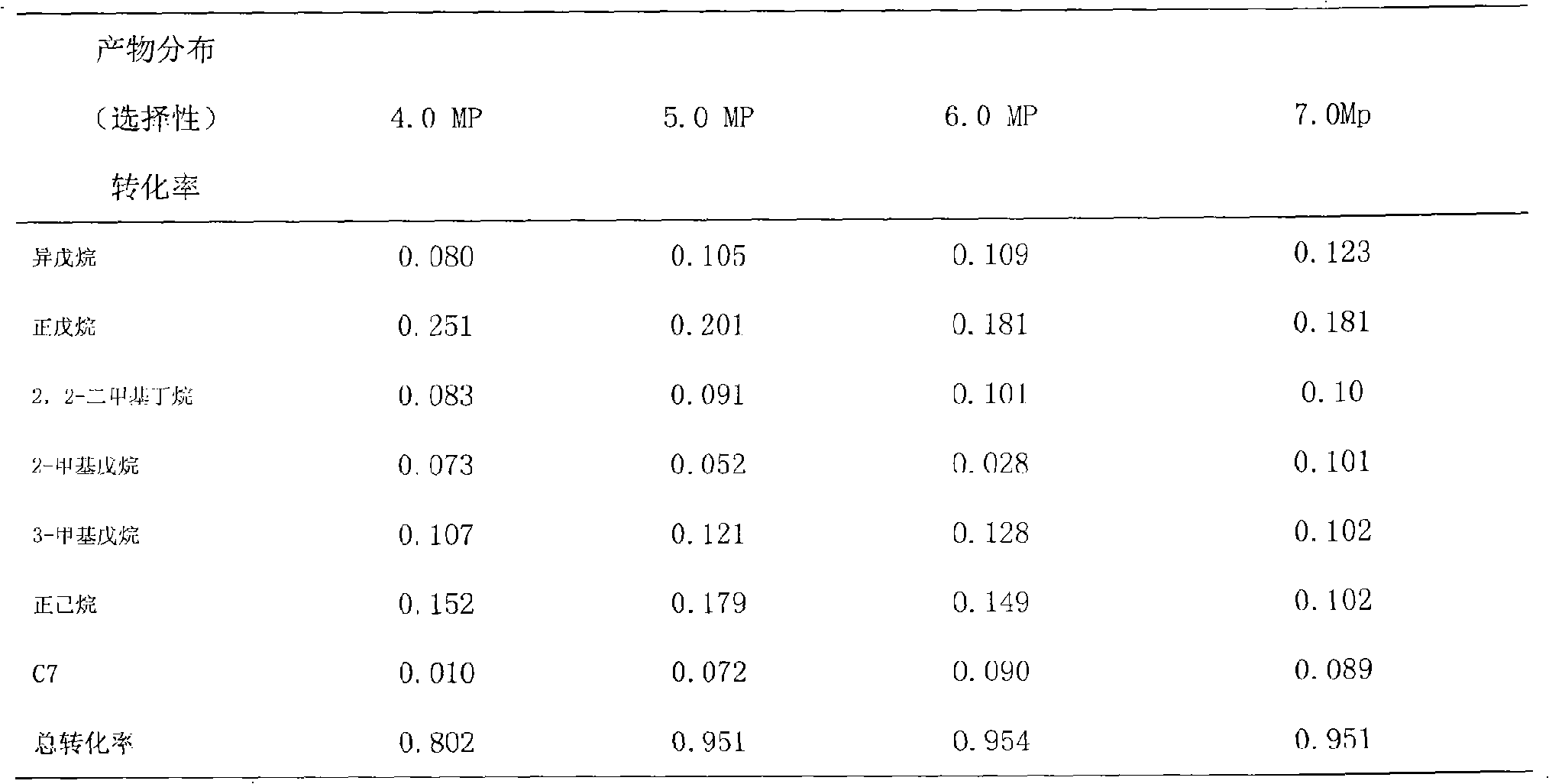

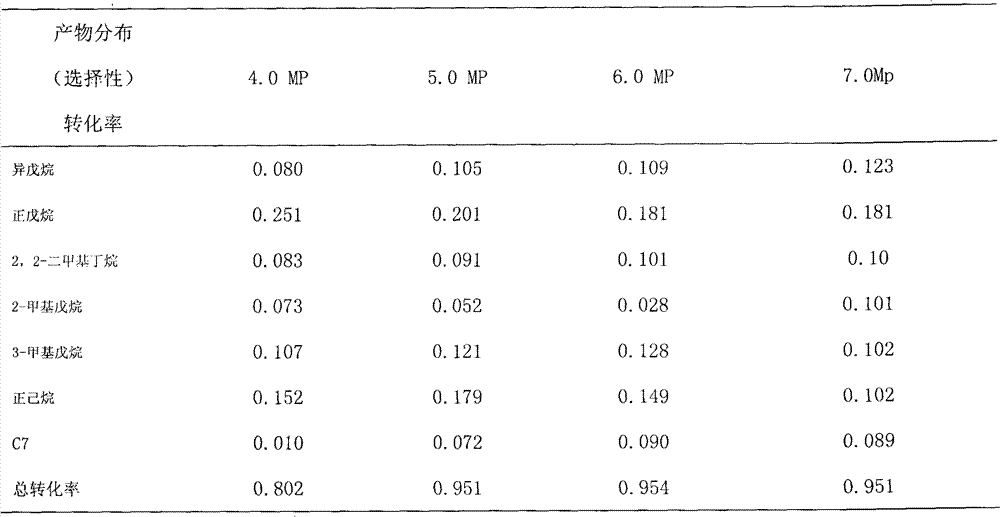

The present invention provide a method of catalyzing sorbitol to synthesize bio-petrol with higher total octane value. Using sorbitol as raw stuff, employing reaction apparatus with minisize high-pressure slurry bed as core, employing load type Pt as catalyst, active component of the load type Pt catalyst is Pt; vectors are HZSM-5 molecular sieve of 20-200 meshes; capacity of the Pt is 0.5-2.0% mass of the vector; mixing the deacidized catalyst and sorbitol solution and added into the slurry bed of the reaction apparatus; accessing hydrogen gas and starting the reaction. The invention employs the load type catalyst Pt to obtain a more than 80% conversion rate and C<5+>, and content of isoalkane in products is higher, consequently increasing the total octane value of products, and the obtained bio-petrol is more suitable for motor petrol.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Activated sludge and microalgae coupled granular system for waste water treatment and establishment and operation method thereof

ActiveCN105174476AIncrease biomassImprove purification effectBiological water/sewage treatmentActivated sludgeBiodiesel

The invention discloses an activated sludge and microalgae coupled granular system for waste water treatment and an establishment and operation method thereof. The activated sludge and microalgae coupled granular system is established for purifying sewage and recycling energy. The system comprises microalgae and a granule sludge carrier thereof. The settling time at the culture stage is controlled to range from 1 min to 100 min, and the drainage ratio of a reactor at the culture stage is controlled to range from 10% to 90%. Shear force formed through aeration or stirring is controlled to range from 0.1 cm / s to 2 cm / s, settling time at the actual waste water treatment stage is controlled to range from 0.5 min to 30 min, the drainage ratio at the actual waste water treatment stage is controlled to range from 10% to 90%, and shear force formed through aeration or stirring is controlled to range from 0.1 cm / s to 3 cm / s. The system can treat various kinds of waste water, and remaining sludge can serve as raw materials for preparation of biodiesel and biogasoline, hydrogen production by fermentation and methane production by fermentation, and preparation of bio-organic fertilizer, biochar and the like.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

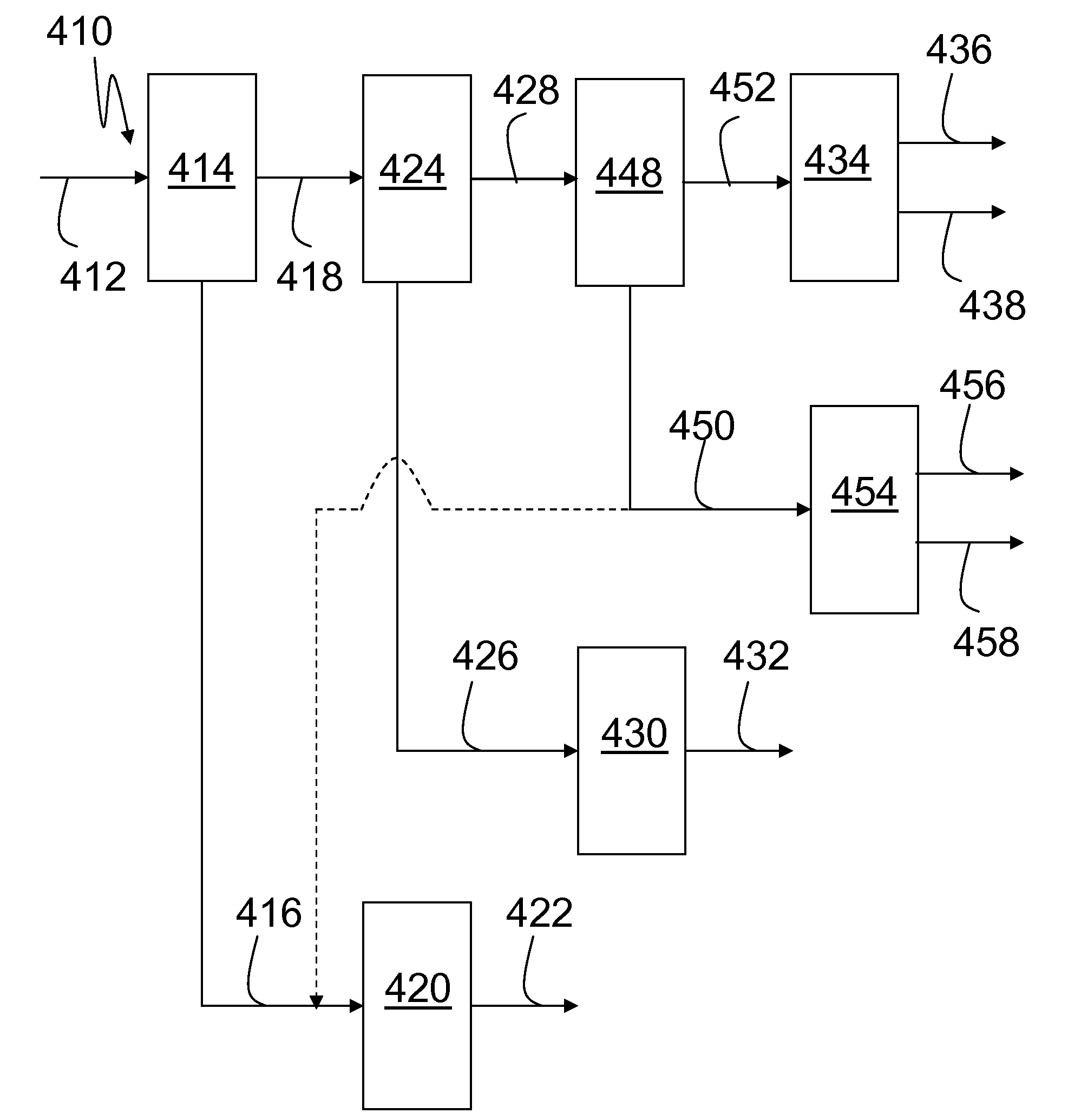

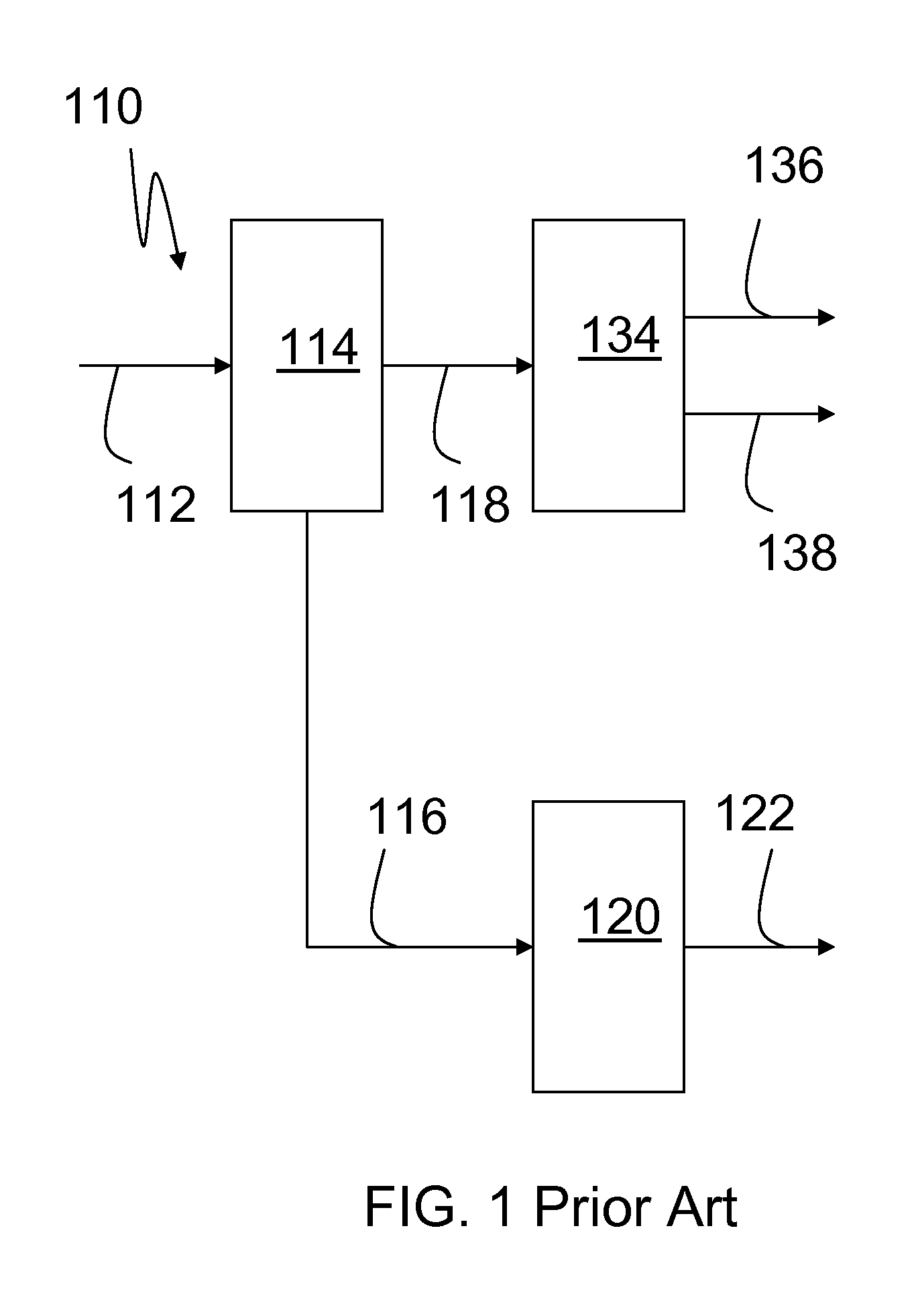

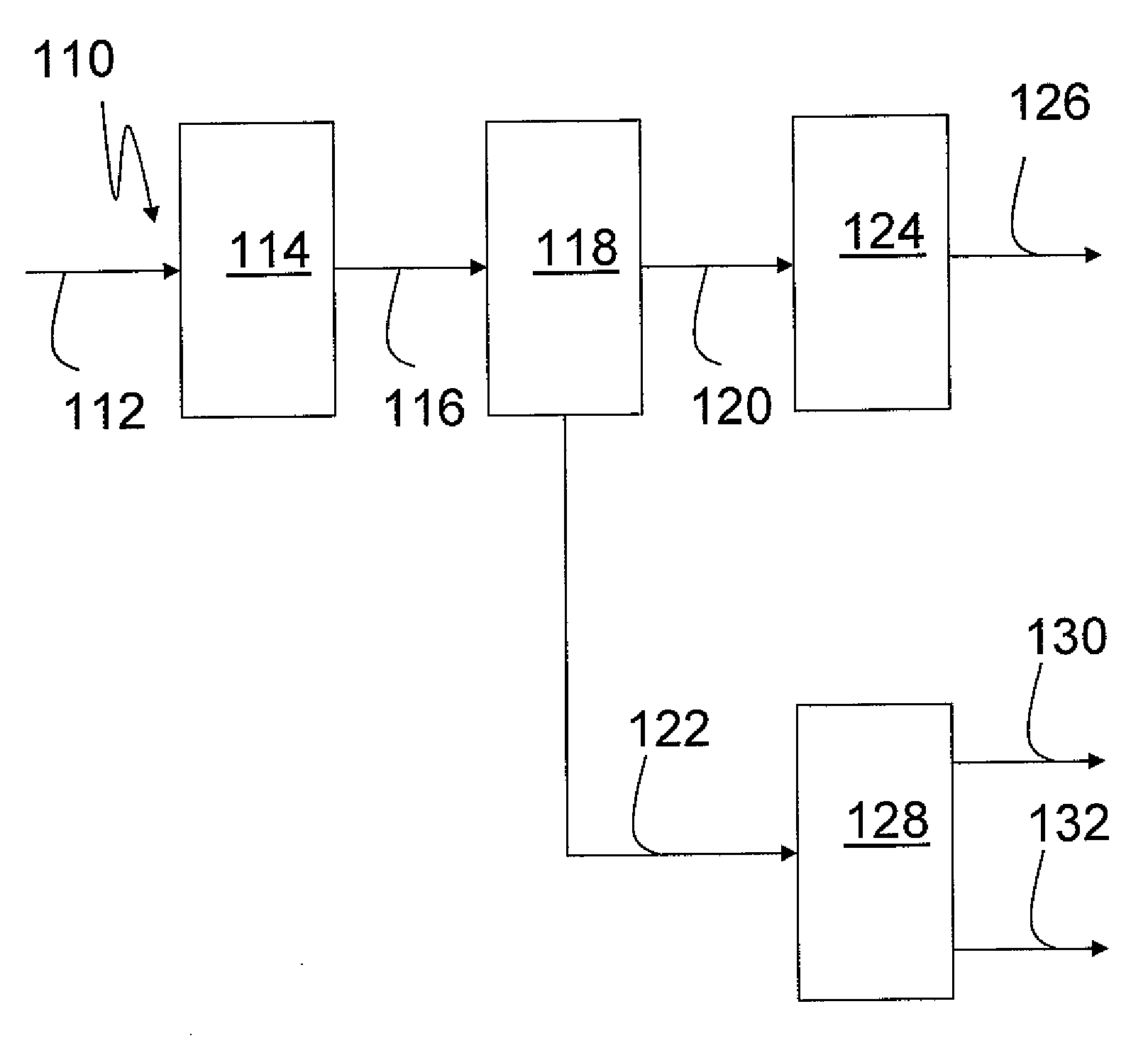

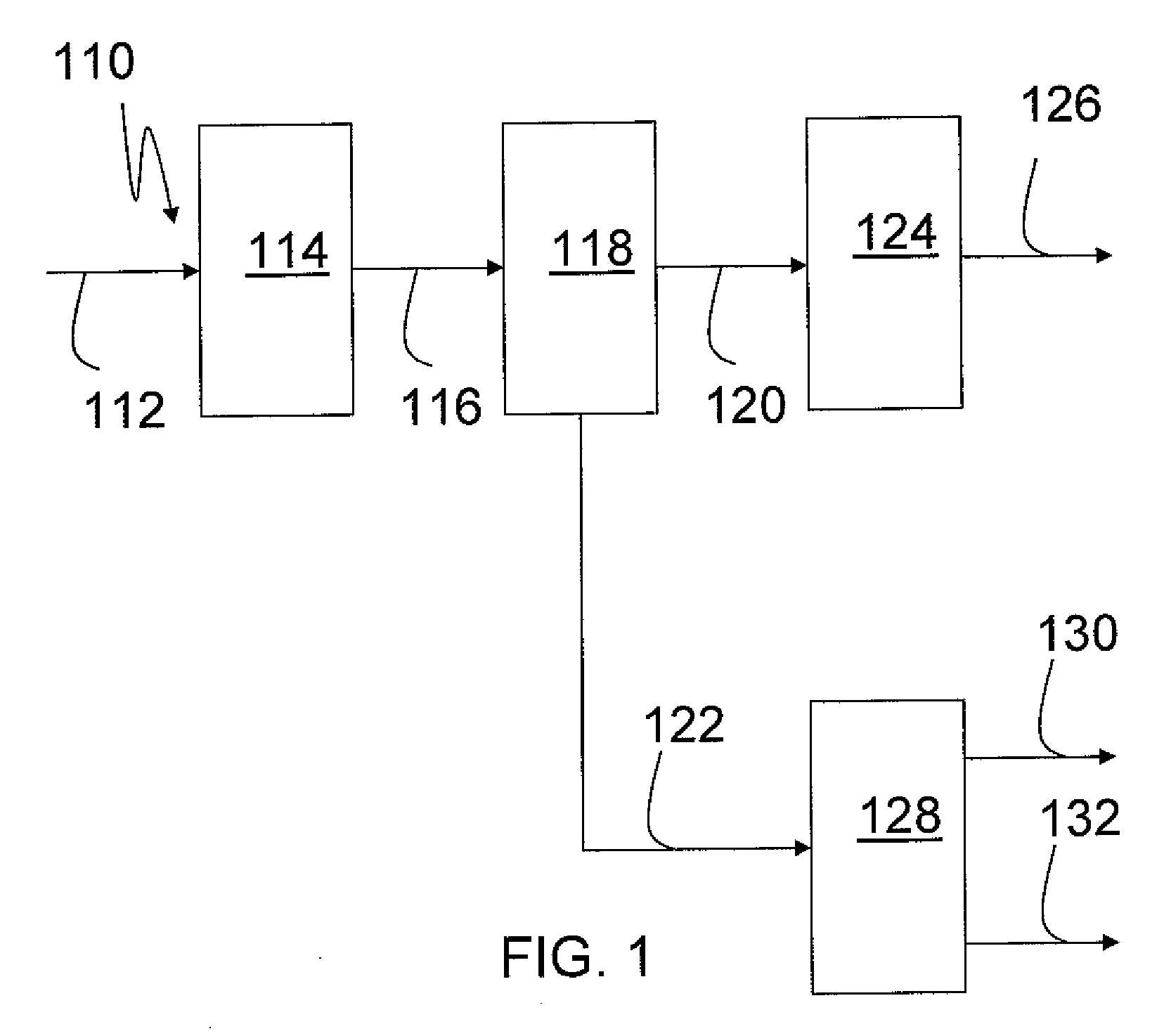

Production of renewable bio-gasoline

A process and system for separating bio-gasoline, bio-diesel and bio-fuel oil fractions from a bio-oil, and for producing a renewable gasoline including at least in part the bio-gasoline fraction, is provided. The process comprises separating bio-oil into a bio-gasoline fraction and a heavy fraction based on their boiling points. At least a portion of the bio-gasoline fraction is directly blended with a petroleum-derived gasoline, without any prior hydrotreatment, to thereby provide a renewable gasoline composition.

Owner:MARD INC

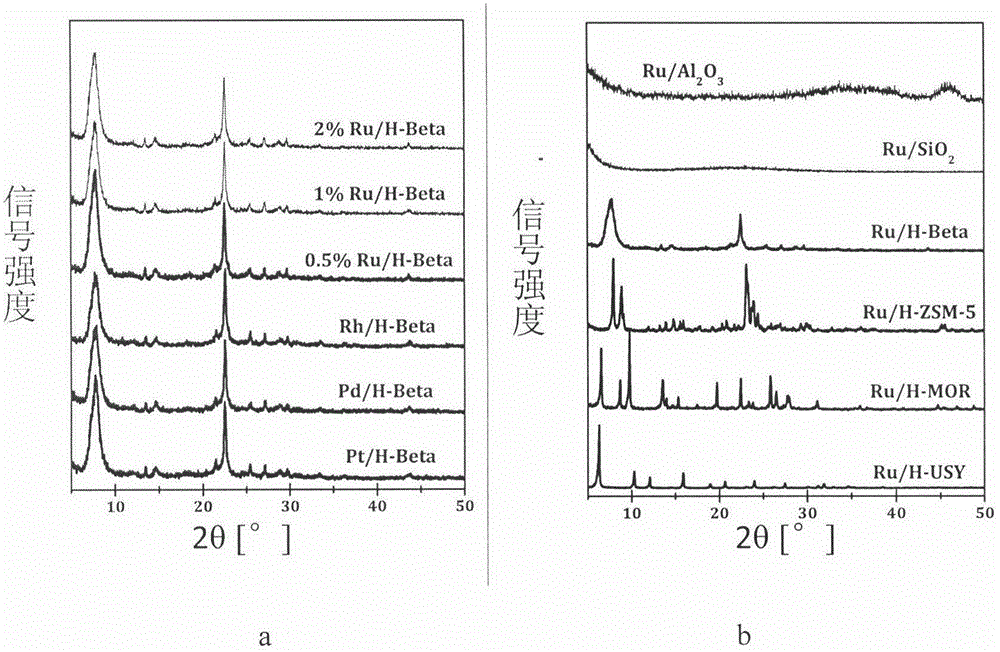

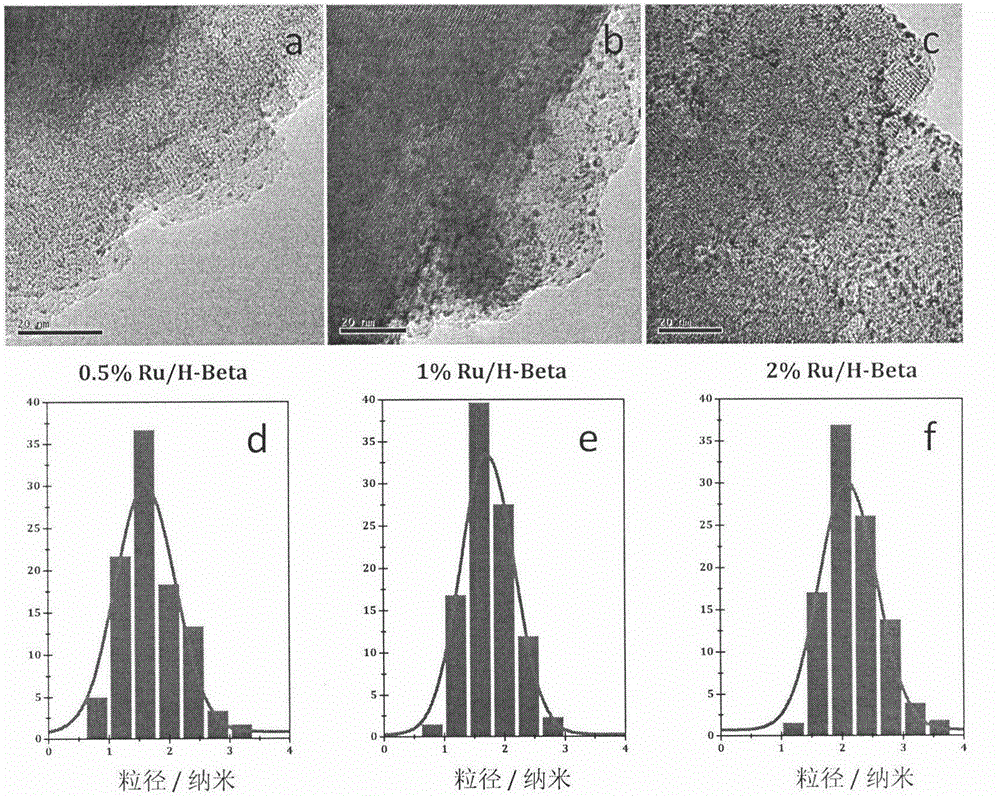

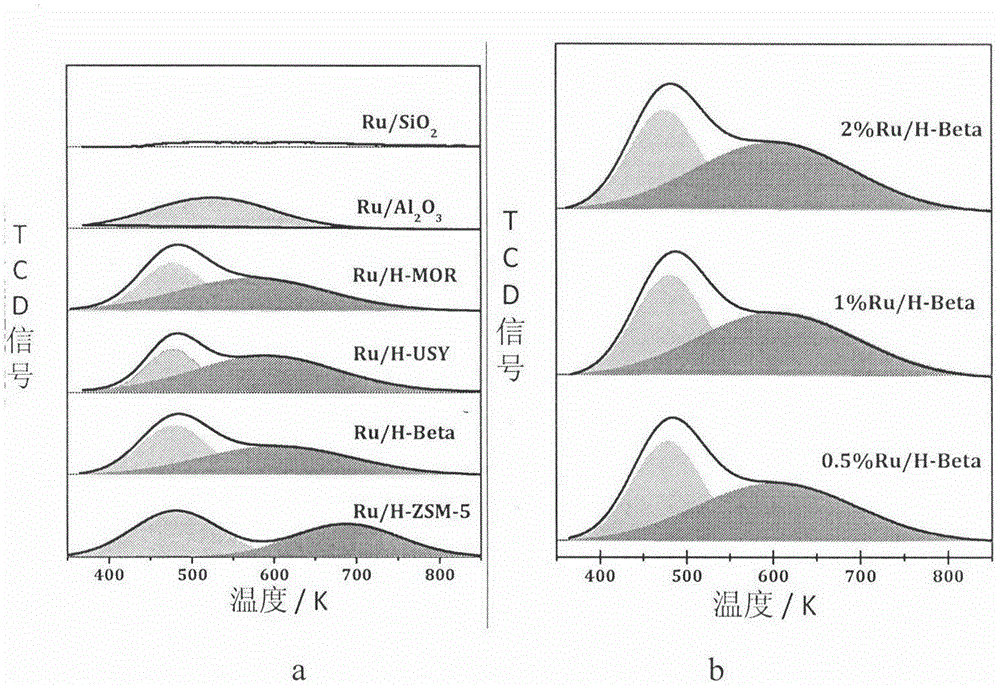

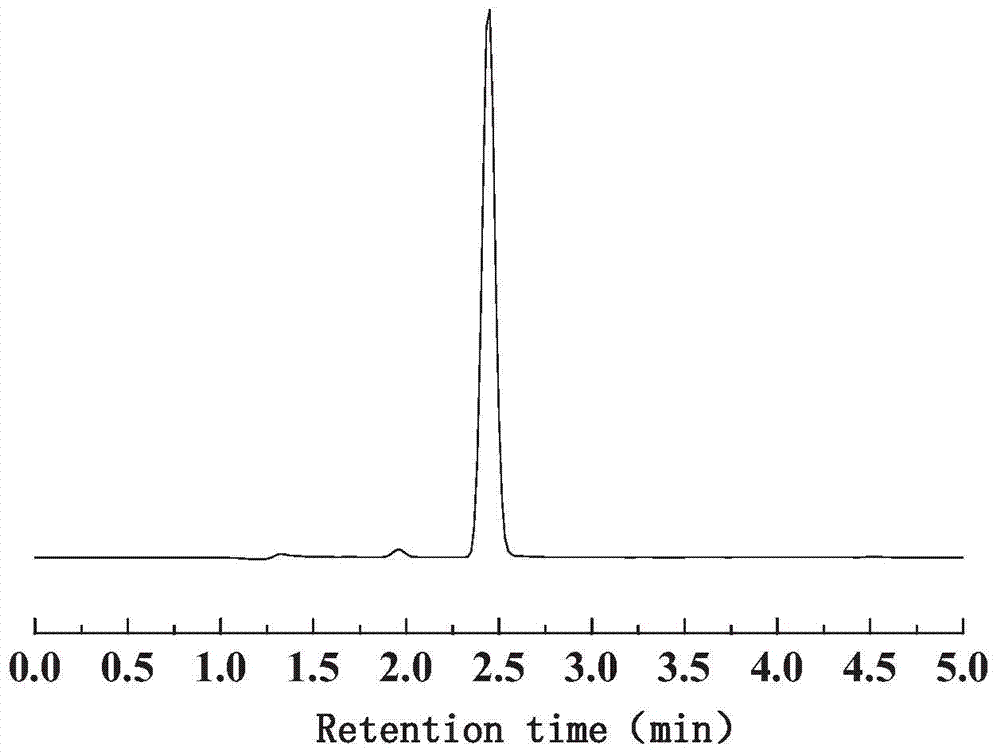

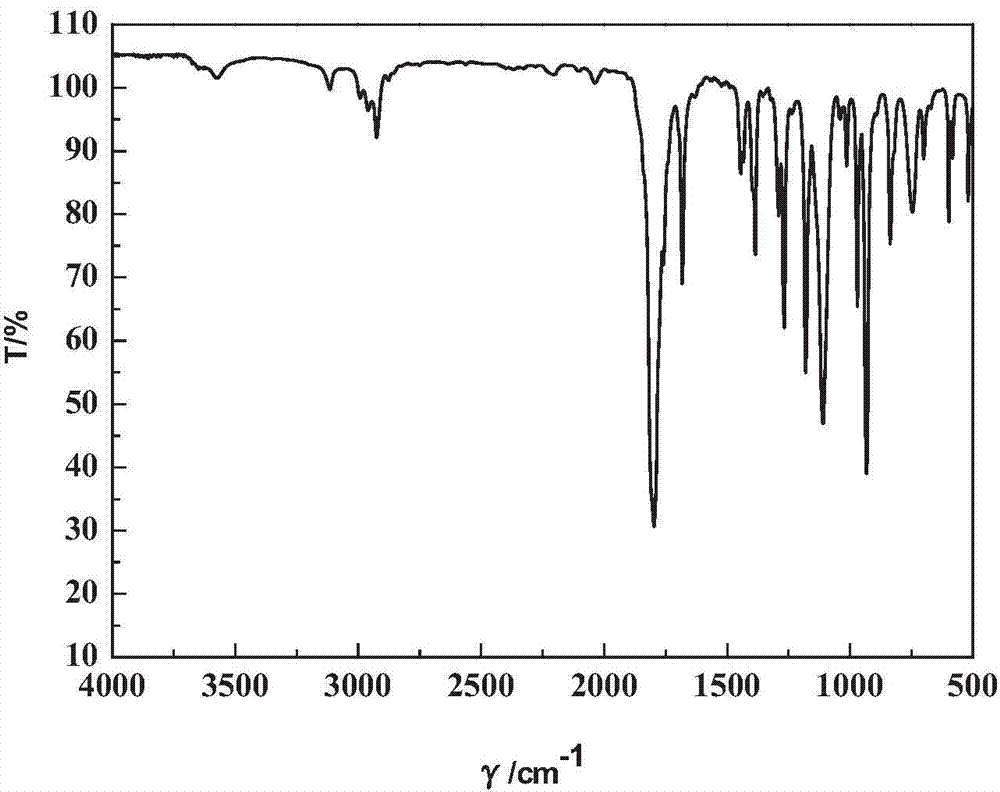

Low-temperature aqueous-phase catalyst for lignin phenol derivative hydrodeoxygenation and preparation method thereof

InactiveCN104624225AHigh selectivityGood choiceMolecular sieve catalystsHydrocarbon from oxygen organic compoundsAlkanePhenol derivative

The invention relates to a low-temperature aqueous-phase catalyst for lignin phenol derivative hydrodeoxygenation and a preparation method thereof. The catalyst comprises a zeolite molecular sieve HBeta serving as a carrier and a load Ru, wherein the molar ratio of silicon to aluminum is 10-50, and the loading amount of Ru is 0.1 to 2%. The preparation method comprises the following steps: mixing measured aqueous solution of RuCl3 with a zeolite suspension, evaporating water and drying, and then reducing the obtained solid with hydrogen / argon mixed gas. A cyclic hydrocarbon (the conversion rate is greater than 98% and the selectivity is greater than 95%) is prepared at high selectivity under the relatively mild (100-150 DEG C and 1-4MPa) condition, so that the defects that the reaction conditions are harsh and the energy efficiency is low in the refining process of biomass pyrolysis oil can be overcome. The bifunctional catalyst provided by the invention has the advantages of simplicity and easiness in operation in the preparation process, stable physical and chemical properties, and direct application. At low temperatures, the catalyst shows excellent hydrodeoxygenation activity and extremely high selectivity of saturated hydrocarbons, has a simple and environment-friendly reaction process, and can be widely used in the refining of bio-gasoline.

Owner:NANKAI UNIV

Process, Plant And Biofuel From Lignocellulosic Feedstock

InactiveUS20100146844A1Bioreactor/fermenter combinationsBiological substance pretreatmentsCelluloseBiodiesel

This invention relates to a process and a plant for biofuel production, such as with biogasoline and / or biodiesel. The process includes the step of depolymerizing lignocellulosic material to form pentose and a remainder. The process also includes the step of converting the pentose to a biofuel material and using the remainder for generation of power or further downstream conversion.

Owner:BP BIOFUELS UK

Environmental protection energy-saving micro-emulsified biological petrol and diesel blended fuel containing seawater, animal-vegetable oils and alcohols, and additive

Owner:ENTERPRISE ENVIRONMENT PROTECTION TECH HONG KONG

Biogasoline

InactiveCN101720349AHighly toxicWill not lose activityCatalytic crackingLiquid carbonaceous fuelsNaphthaGasoline

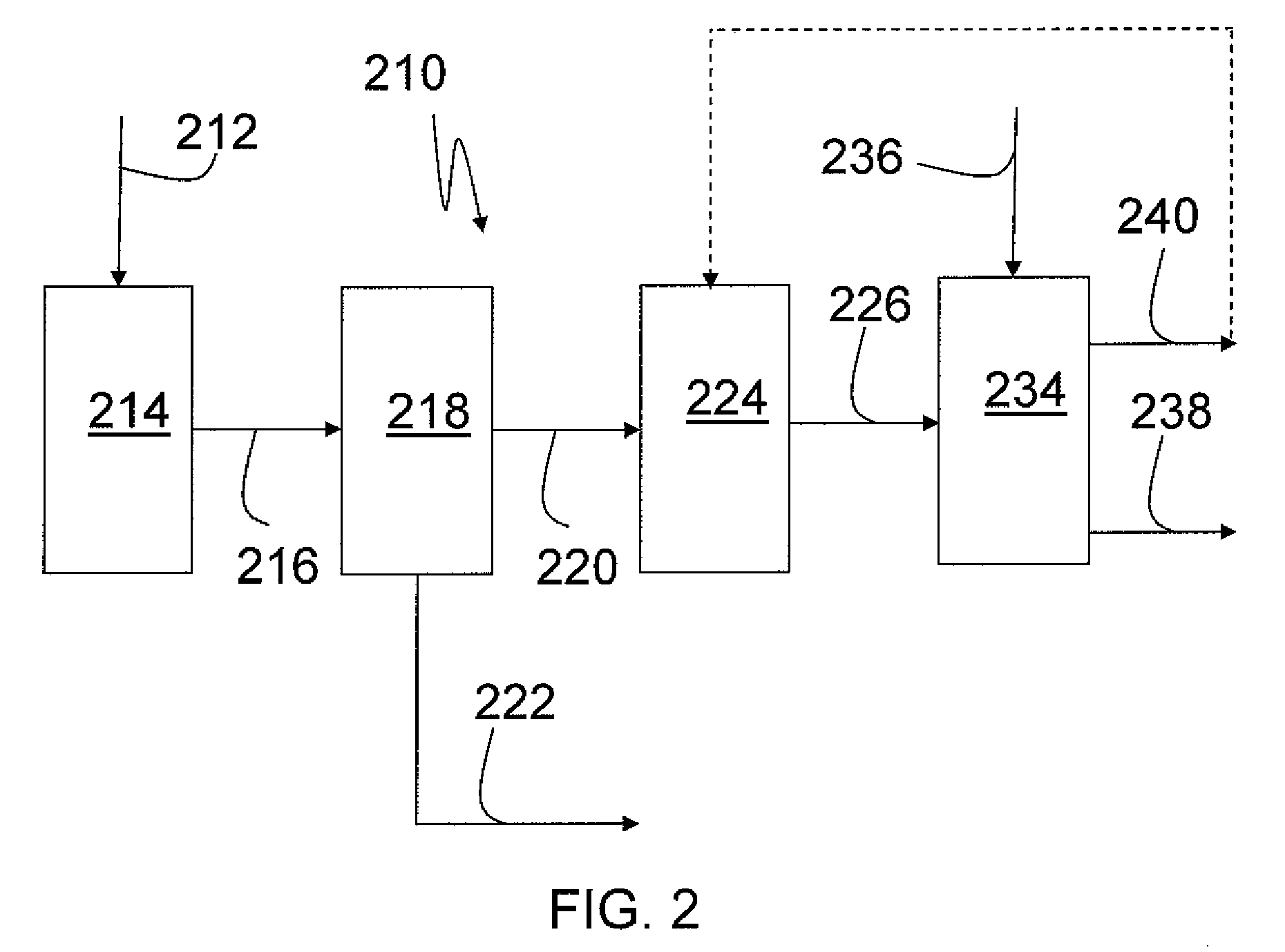

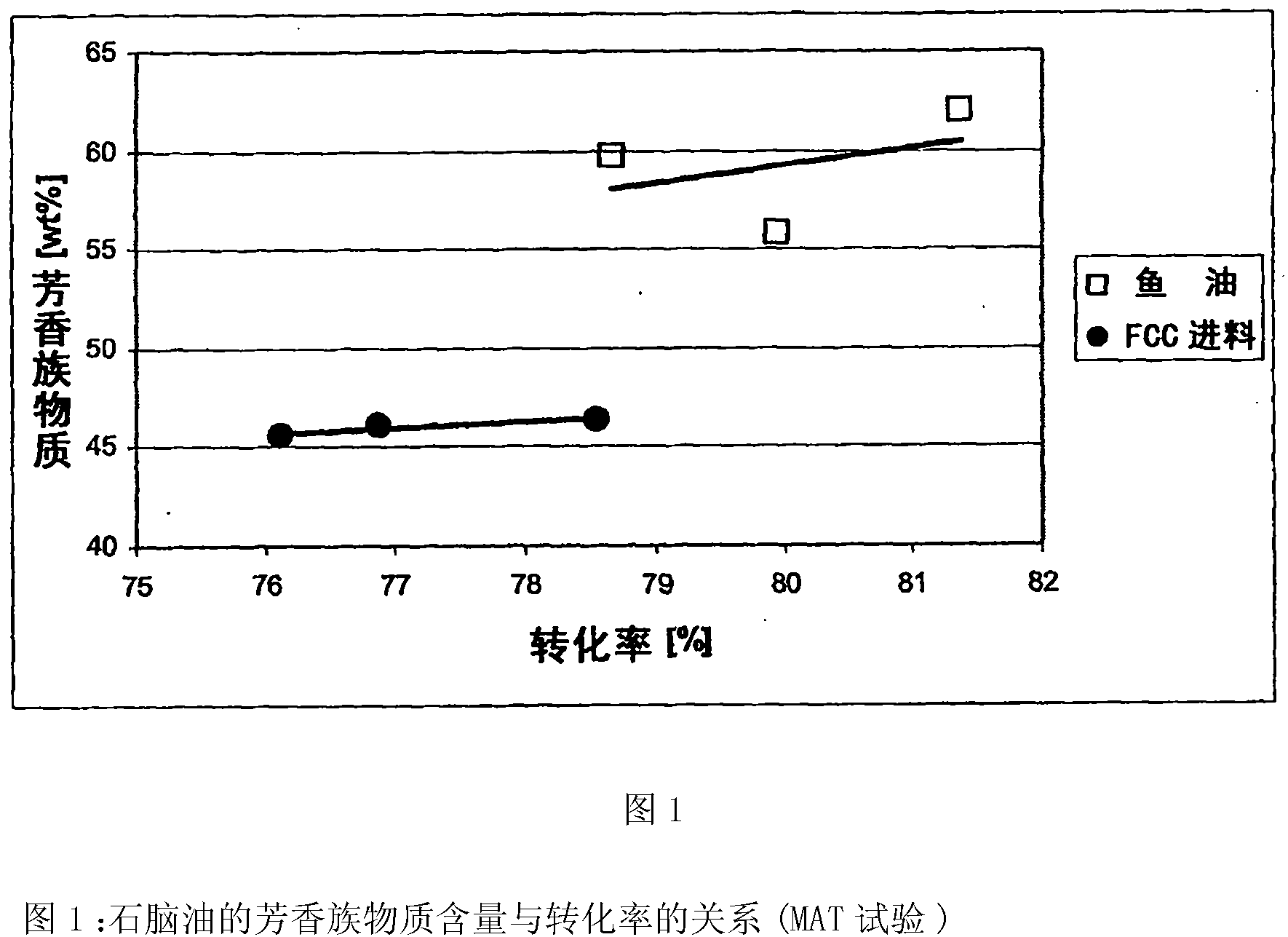

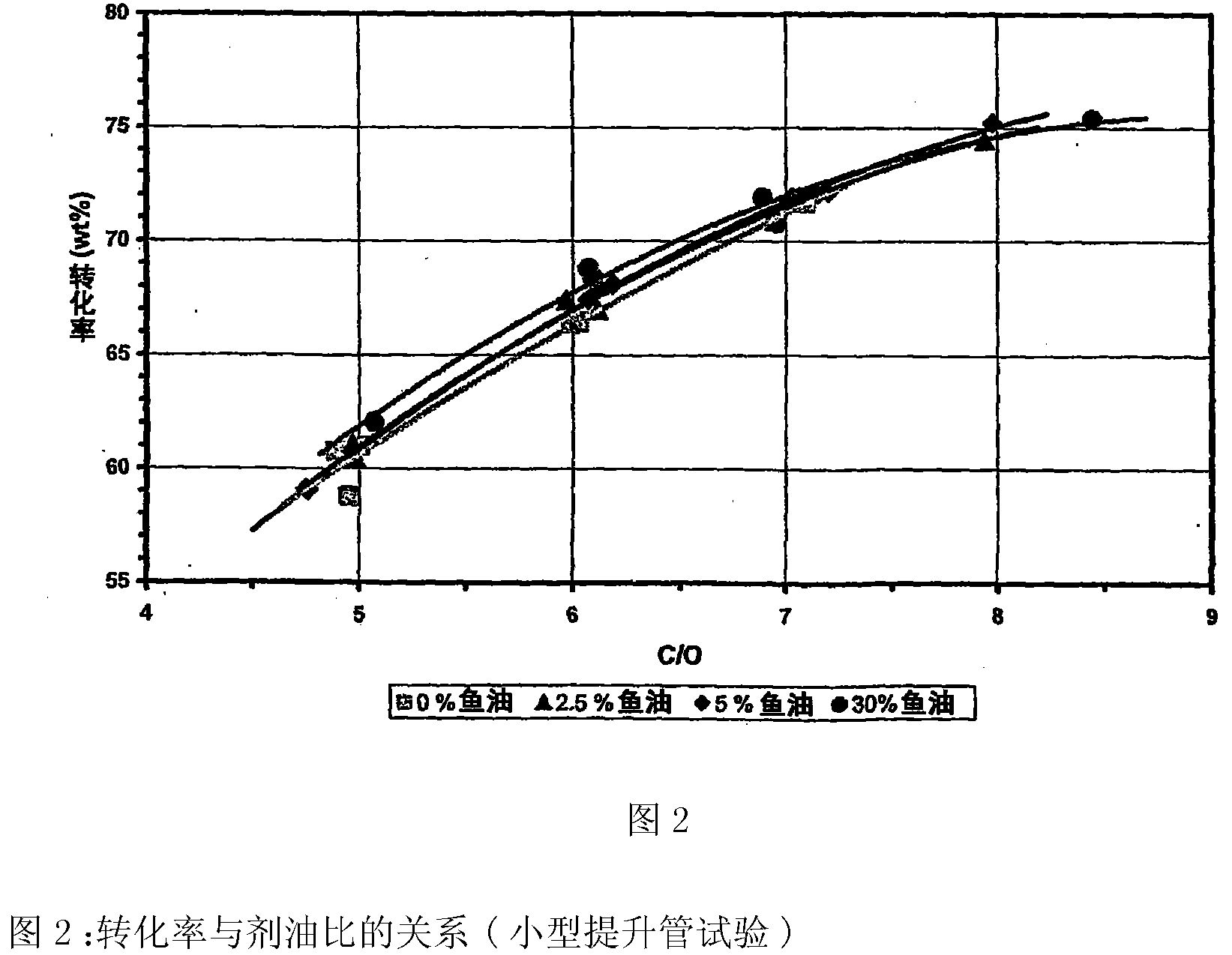

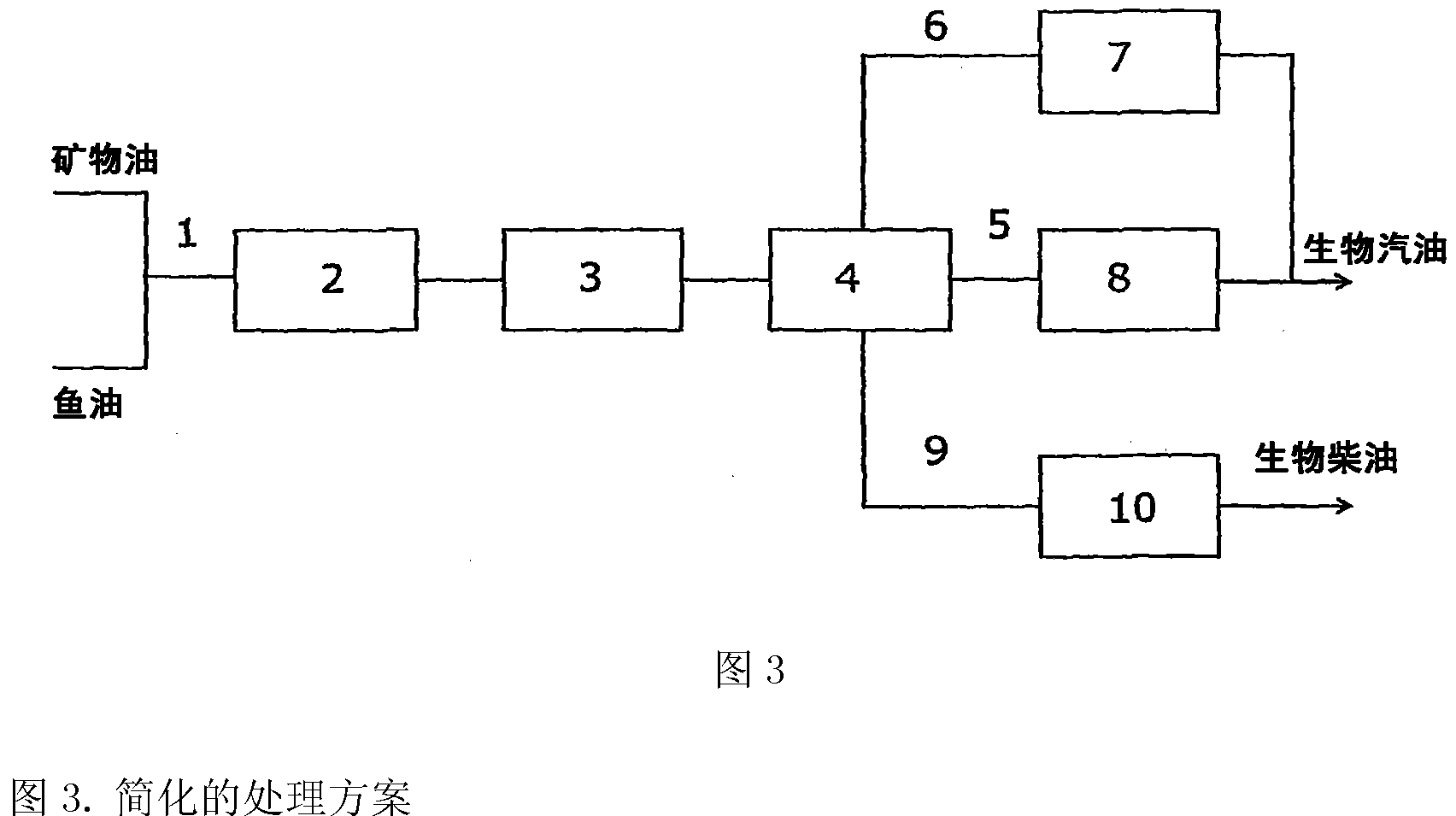

A process for the preparation of a biogasoline component comprising: (I) obtaining at least one bio-oil and, if necessary, liquefying the bio-oil component; (II) adding the bio-oil in liquid form to a FCC unit along with at least one mineral oil; (III) cracking the components added to the FCC unit to form at least a bio-LPG fraction and a bio-naphtha fraction; (IV) alkylating or catalytically polymerising at least part of the bio-LPG fraction; and (V) combining at least a part of the product of step (IV) with at least a part of the bio-naphtha fraction to form a bio-gasoline component.

Owner:DEN NORSKE STATS OLJESELSKAP AS

Method for preparing biogasoline by catalytic hydrogenolysis on straws

InactiveCN109161395AAvoid lostMaximize utilizationLiquid hydrocarbon mixture productionHydrocarbon oils treatment productsFuranIodide

The invention provides a method for preparing biogasoline by catalytic hydrogenolysis on straws. The method comprises the following steps: successively adding the straws, iodide, a metal catalyst, water, an organic solvent and inorganic acid in a reaction container according to a certain rate of charge, after feeding hydrogen until pressure in the reaction container reaches a certain range, heating the reaction container to a certain temperature and then reacting for a certain time, then cooling to a room temperature and collecting an organic phase. The prepared product mainly comprises 2-methyltetrahydrofuran, 2-methyl furan, 2,5-dimethyl tetrahydrofuran, 2,5-dimethylfuran, 2-hexanone, 3-methylcyclopentanone, 2,5-hexanedione and 5-methylfurfural. By the method, the straws are catalytically hydrogenated by metal under the conditions of low temperature and low pressure, and cellulose and hemicellulose portions in the straws are directly converted into furan, furfural and a cyclic ketones compound at high yield.

Owner:NANCHANG UNIV

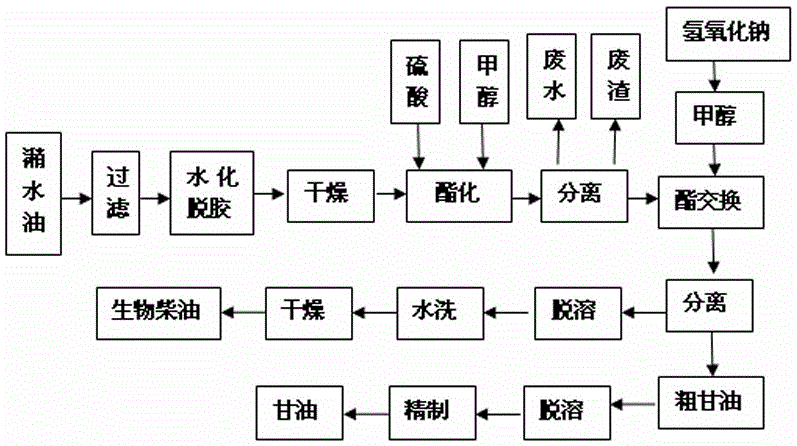

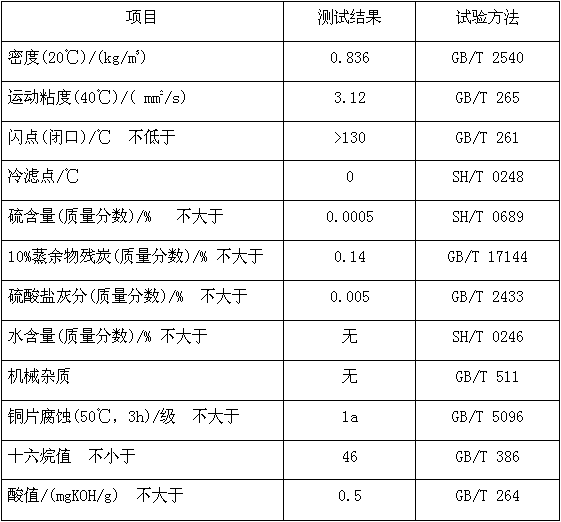

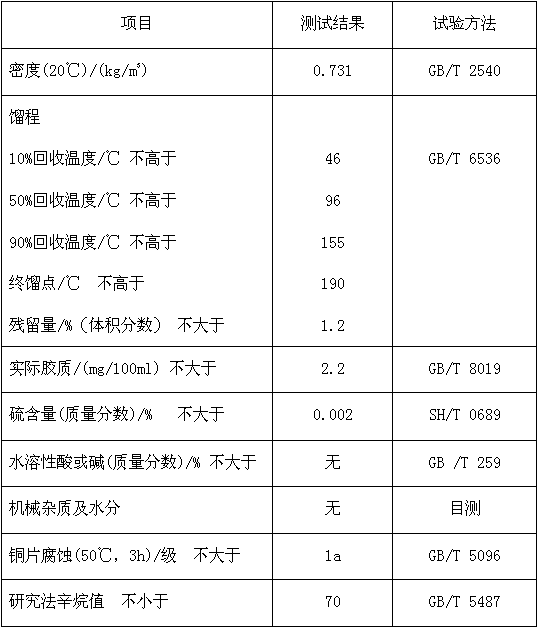

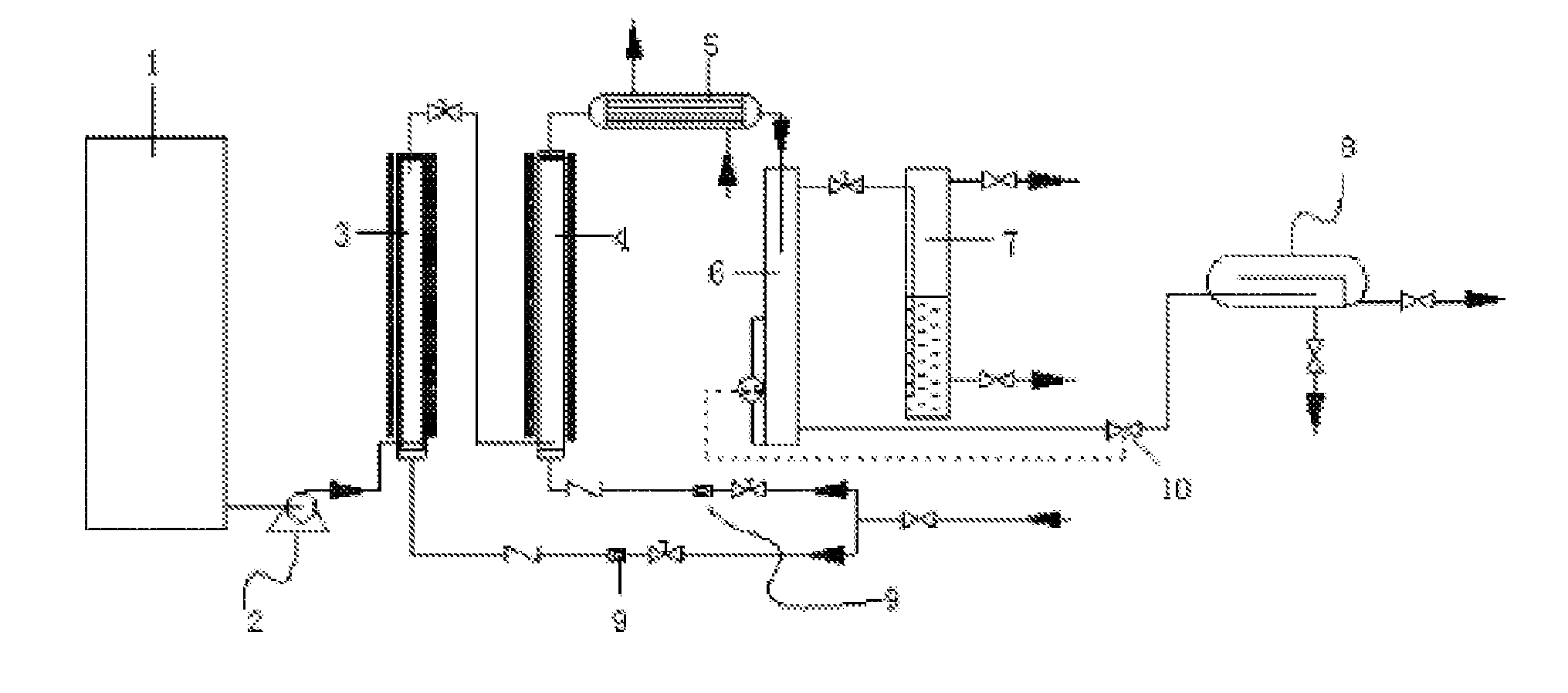

Method for preparing biodiesel by catalytic cracking

The invention relates to a method for preparing biodiesel through catalytic cracking from vegetable oil under the action of a catalyst, which comprises the following operation steps: heating the vegetable oil and then performing flash vaporization on the vegetable oil when the temperature is between 130 and 170 DEG C to remove water vapor and light components; heating the vegetable oil after the flash vaporization to react with the catalyst at a temperature of between 360 and 450 DEG C, wherein the space velocity of the catalyst is between 0.5 and 1 ton / hour.ton catalyst; performing secondary catalytic reaction on the reaction products obtained in the step with the same catalyst with the space velocity of between 0.5 and 1 ton / hour.ton catalyst; and performing distillation separation on the prepared catalytic product with the feed temperature of between 350 and 380 DEG C to prepare biological gasoline, the biodiesel and residual oil respectively. The biodiesel prepared by the method has the advantages of excellent environmental protection property, better low temperature engine starting performance, and better lubrification.

Owner:王英国 +1

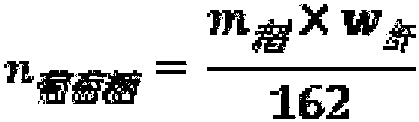

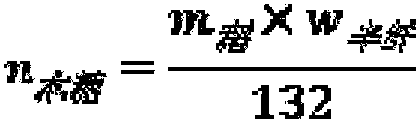

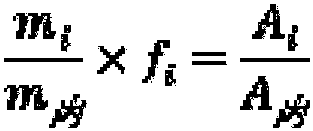

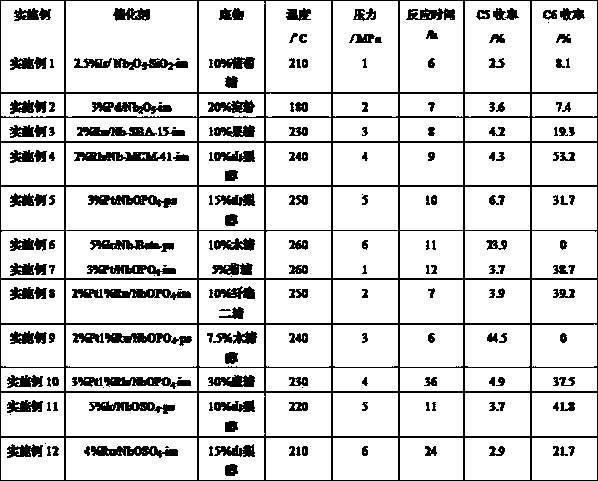

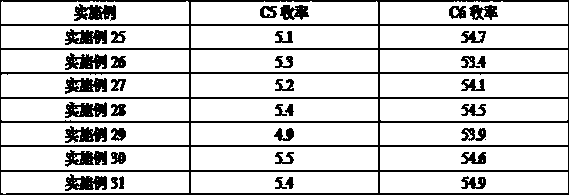

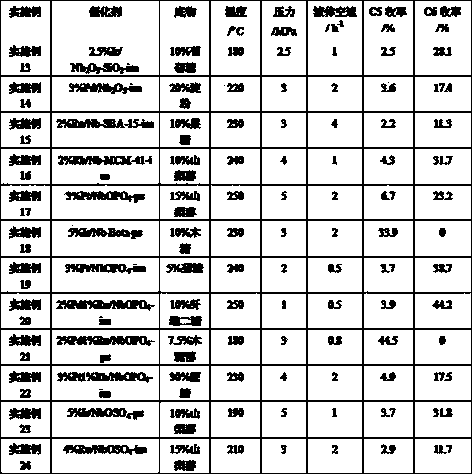

Catalyst for preparing C5,C6 light alkane from carbohydrate

InactiveCN103962173AHigh activityHigh yieldMolecular sieve catalystsHydrocarbon from oxygen organic compoundsAlkaneNiobium

The invention relates to a catalyst for preparing C5,C6 light alkane from carbohydrate and a process of the catalyst and belongs to the research fields for preparing fuels and chemicals from a biomass and derivatives of the biomass. The catalyst comprises two active ingredients, namely an acid center adopting a carrier containing Nb and a metal hydrogenation activity with Rh, Pd, Pt, Ir and Ru, wherein the acid center adopting the carrier containing the Nb can dehydrate hydroxide radical of the carbohydrate, NbOx further can break a C-O bond, and the light alkane is generated by virtue of synergistic effect between the acid center and the metal hydrogenation activity center with Rh, Pd, Pt, Ir and Ru. The catalyst has the advantages that by taking glucose as a raw material, the total yield of C5 and C6 can reach 60% under an optimal reaction condition; the catalyst has high activity, is easy to separate and recycle, is good in stability and has a good industrial application prospect, and a valuable novel way is provided for converting the carbohydrate into biogasoline.

Owner:EAST CHINA UNIV OF SCI & TECH

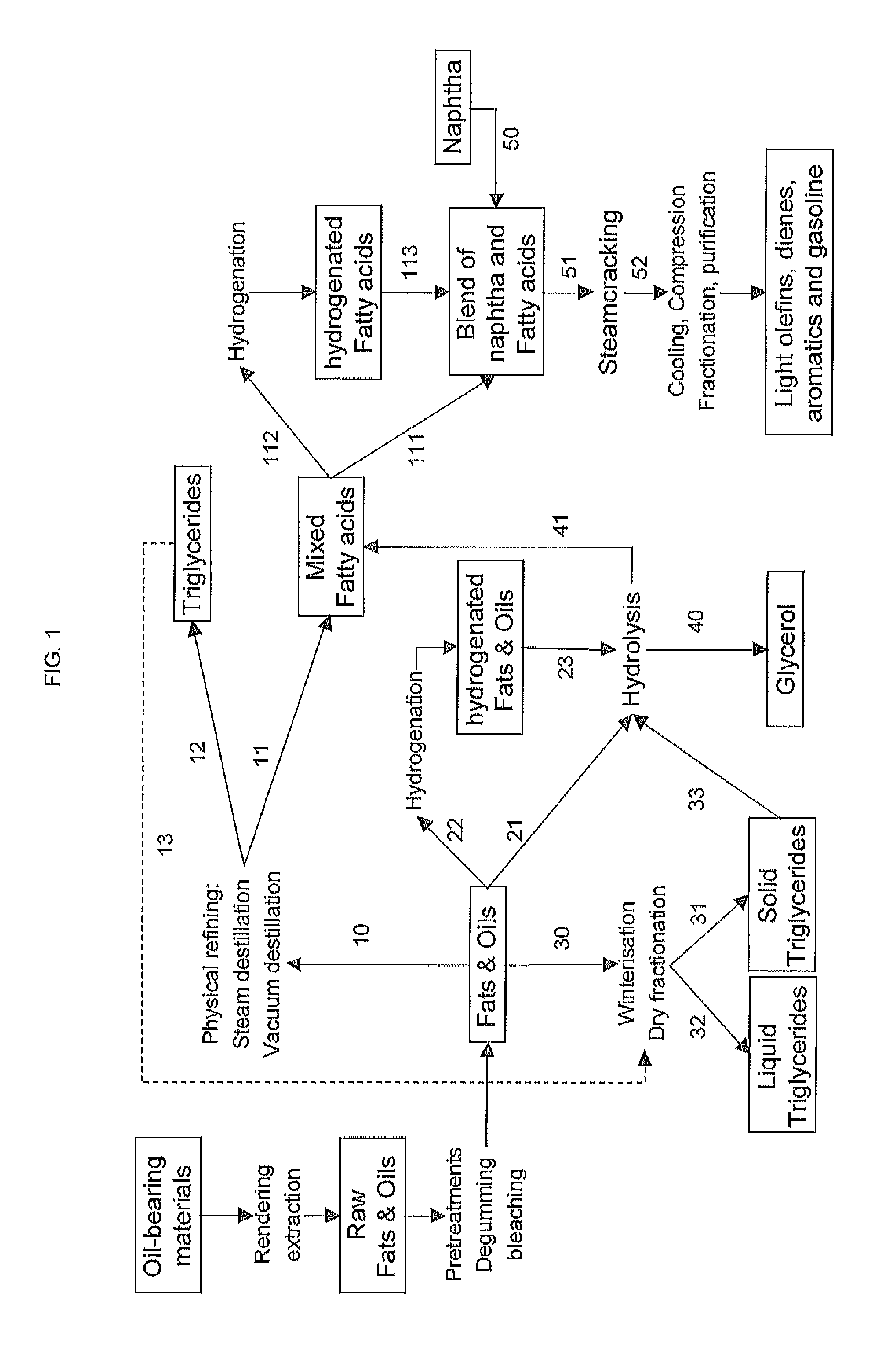

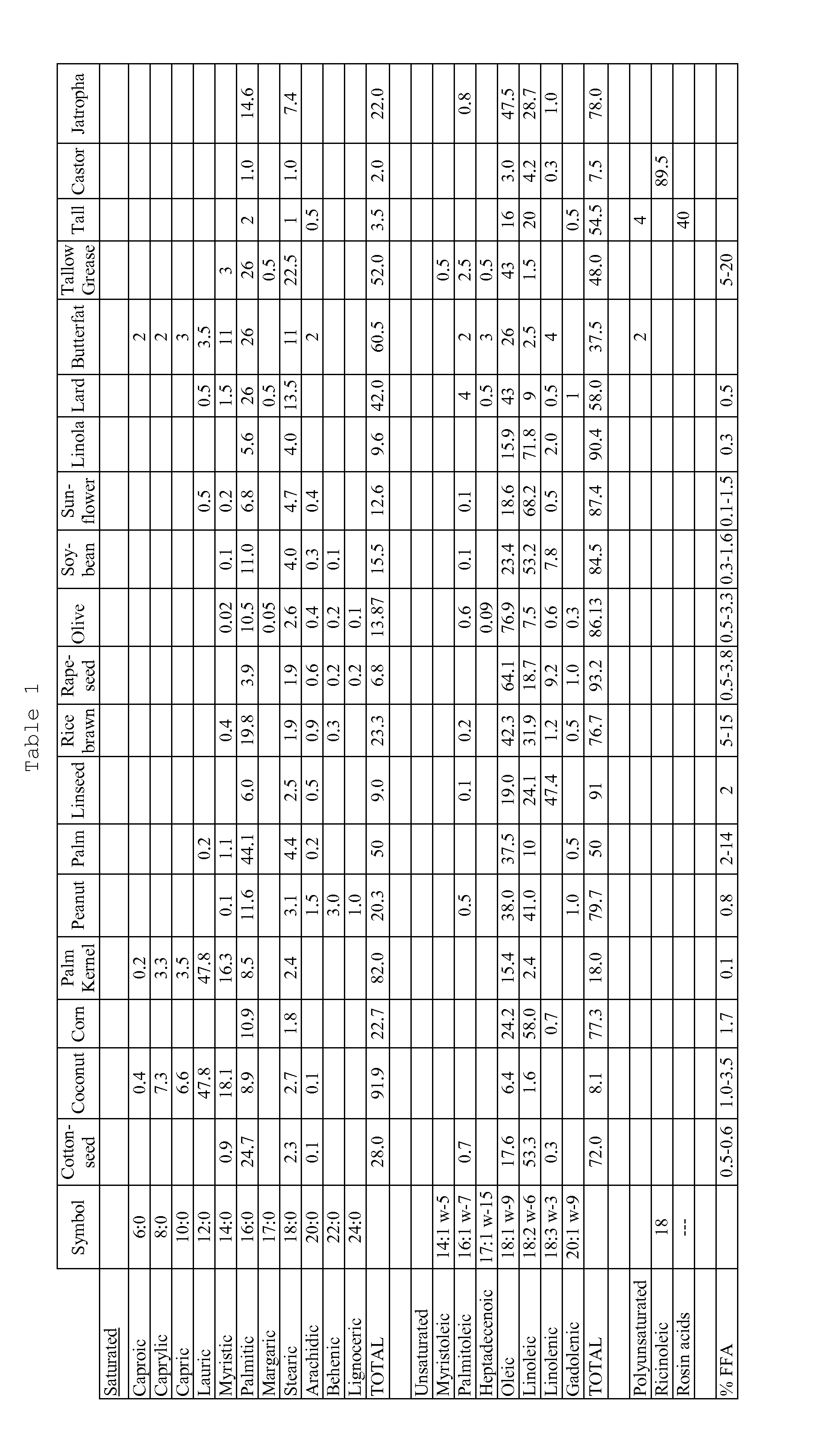

Use of free fatty acids produced from bio-sourced oils & fats as the feedstock for a steamcracker

InactiveUS20120142982A1Fatty acid chemical modificationLiquid carbonaceous fuelsGasolineTG - Triglyceride

Use of fatty acids produced from a complex mixture of natural occurring oils & fats and / or of triglycerides deriving from said complex mixture as the feedstock of a steamcracker, by mixing the fatty acids with steam in a steam / feedstock ratio of at least 0.2 kg per kg, a coil outlet temperature of at least 700° C. and an coil outlet pressure of at least 1.2 bara in order to obtain cracking products including bio-ethylene, bio-propylene, bio-butadiene, bio-isoprene, bio-cyclopentadiene and bio-piperylenes, bio-benzene, bio-toluene, bio-xylene and bio-gasoline.

Owner:TOTAL RES & TECH FELUY

Process, Plant, and Biofuel From Lognocellulosic Feedstock

InactiveUS20100251608A1Bioreactor/fermenter combinationsBiological substance pretreatmentsCelluloseBiodiesel

This invention relates to a process and a plant for biofuel production, such as with biogasoline and / or biodiesel. The process includes the step of depolymerizing lignocellulosic material to form pentose and a remainder. The process also includes the step of converting the pentose to a biofuel material and using the remainder for generation of power or further downstream conversion.

Owner:BP BIOFUELS UK

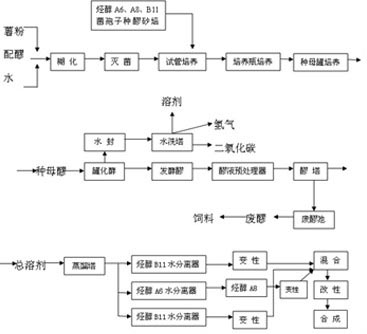

A kind of biogasoline and preparation method thereof

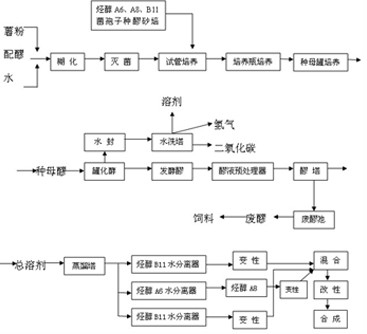

InactiveCN102277211AIncrease powerExtended service lifeLiquid carbonaceous fuelsFermentationYeastAlcohol

The invention relates to a biogasoline and a preparation method thereof. It is made by mixing potato starch, denatured additives, modifiers, and hydrocarbon alcohol strains. The mass percentage of each component is: potato starch 90-98%, denatured additives 1-5%, modifier 1 -5%, hydrocarbon alcohol strain 0.01-1%. Mix the above potato starch with mash→gelatinization→sterilization→hydrocarbyl alcohol A6, A8, B11 bacteria test tube culture→culture bottle culture→breed mother tank culture→breed mother mash→tank fermentation→fermentation mash→mash pretreatment Process → mash tower → total solvent → distillation tower → then synthesize hydrocarbon alcohol A6, hydrocarbon alcohol A8, hydrocarbon alcohol B11 → mix → denaturant and modifying agent. The product of the invention is energy-saving and environment-friendly, has low use cost and prolongs the service life of the engine.

Owner:宋元领

Preparation method of novel bio-gasoline

ActiveCN103710057AReduce pollution pressureAbundant and cheap resourcesLiquid carbonaceous fuelsChemical industryHigh energy

The invention relates to the technical field of biomass energy and chemical industry, particularly to a preparation method of novel bio-gasoline. The method adopts citric acid industrial waste thallus Aspergillus niger as a raw material, and by means of the intermediate products chitin, 5-hydroxymethylfurfural, and 5-ethoxy methyl furfural, the bio-gasoline can be prepared. The preparation method of novel bio-gasoline provided by the invention uses citric acid industrial waste thallus Aspergillus niger as the raw material, so that the pressure of environmental pollution can be substantially relieved, and the prepared bio-gasoline product has high energy density. Also, combustion in the engine is smooth and thorough, and the carbon deposits are fewer.

Owner:山东星火知识产权服务有限公司

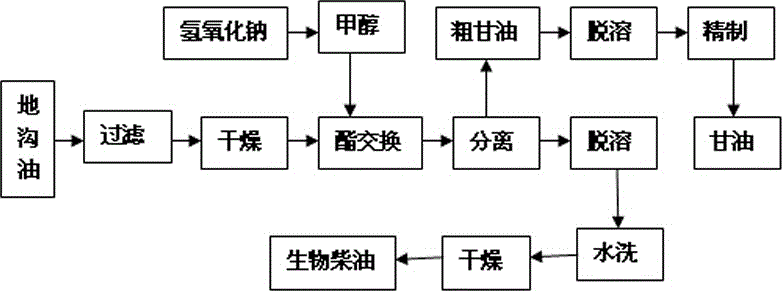

Method for preparing biomass fuel from nanometer materials under catalytic cracking

InactiveCN106190277AWide versatilityVersatileTreatment with plural serial stages onlyOil and greaseBiodiesel

The invention discloses a method for preparing biomass fuel from nanometer materials under catalytic cracking. The method comprises the following steps: performing dehydration treatment on such raw material oil as swill-cooked dirty oil, acidic oil, waste animal and vegetable grease, and separating to remove water and impurities; pumping the dehydrated grease into a tubular heating furnace by a high-temperature oil pump so as to gasify the grease to form a grease vapor and heavy oil mixture, separating the heavy oil by a catalytic fractionating tower at the bottom of the tower, performing catalytic cracking reaction on the pure grease vapor by a catalyst layer, reducing the molecular weight of the grease, removing groups, such as carboxyl and glycerinum, from the grease molecules, and generating hydrocarbon-type oil, liquefied gas and combustible gas; performing preliminary purification on the diesel part of the hydrocarbon-type oil by a steam stripping method and then performing deacidifying stable coalescence treatment; and adsorbing by an adsorbent and separating to obtain biodiesel and biogasoline. The method provided by the invention has the characteristics of high universality, easily available material, excellent property, wide application, simple process, high quality consistency, high additional value and low cost.

Owner:深圳市中创新能源科技有限公司

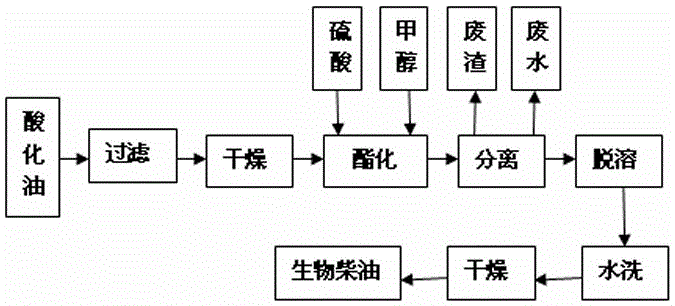

Method for producing clean fuels by catalyzing and cracking animal and vegetable oil

InactiveCN103194255ARich sourcesLow priceLiquid hydrocarbon mixture productionBio-feedstockOil and greaseVegetable oil

The invention discloses a method for producing clean fuels by catalyzing and cracking animal and vegetable oil. The method comprises the following steps: (1), removing impurities from waste animal and vegetable oil serving as raw material, heating up the animal and vegetable oil with impurities removed to 90 DEG C to 95 DEG C by a heater, and dehydrating the heated animal and vegetable oil by a flash evaporation system until the moisture content of the heated animal and vegetable oil is 0.2%; (2), pumping the dehydrated and impurities-removed waste animal and vegetable oil to a catalytic reaction kettle, adding composite catalyst to the catalytic reaction kettle, stirring and heating up to 290 DEG C and keeping the reaction temperature at 290 DEG C to 320 DEG C; and (3), guiding the generated gas to a distillation tower, separating through the distillation tower to obtain bio-gas, bio-gasoline, biodiesel and boiler fuel. Compared with the conventional method for producing biodiesel by an esterification method or an ester exchange method, the method disclosed by the invention has the advantages that the composite catalyst is used to replace concentrated sulfuric acid as a catalyst, carbinol is not needed, almost no environment pollution is caused, the corrosion to the device is avoided and sewage disposal is avoided. Besides, resources are saved, the risk that a dining table due to reflowing of the waste animal and vegetable oil is illegally used in cooking at present can be avoided, and the waste materials are recycled.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

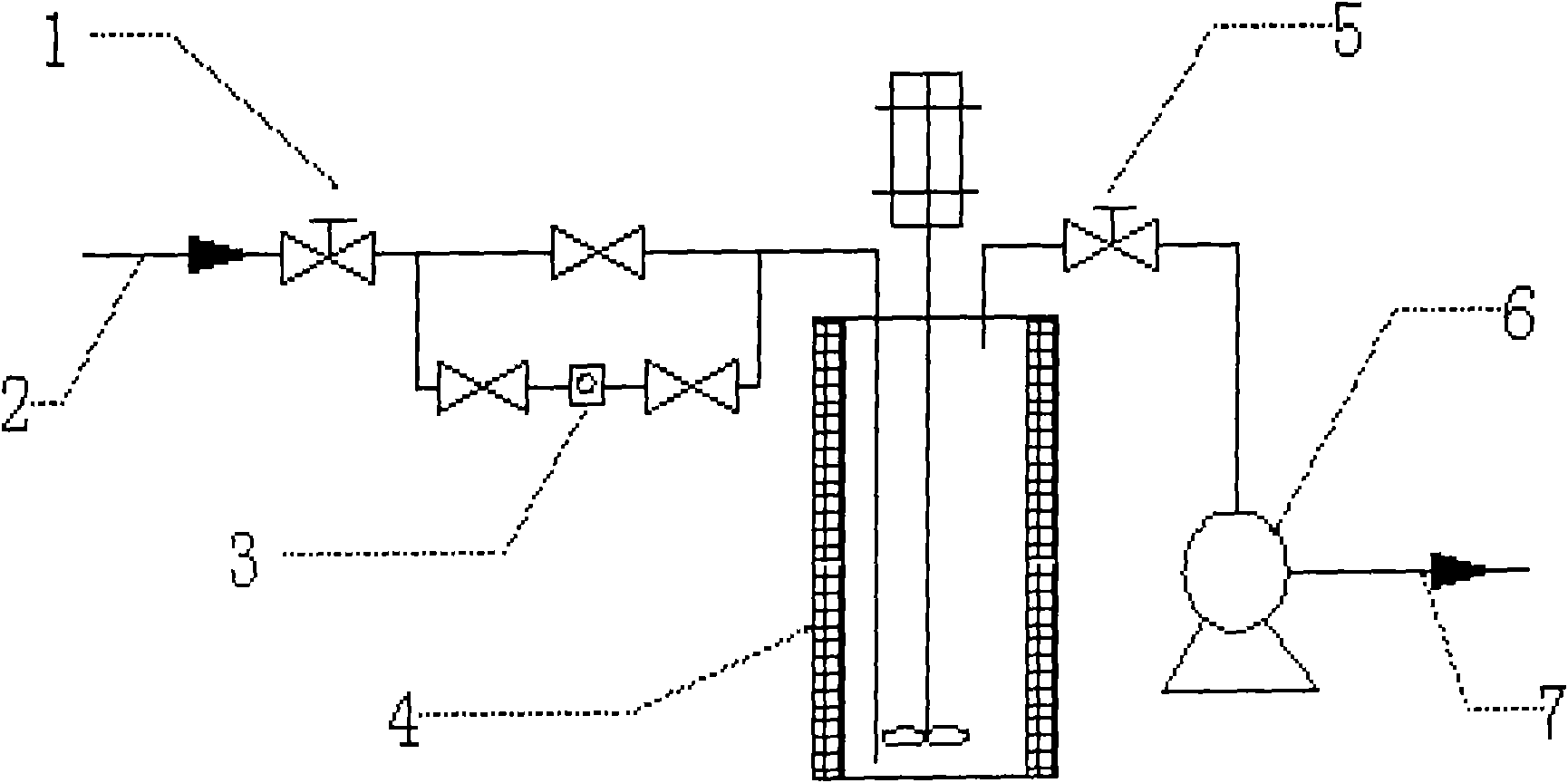

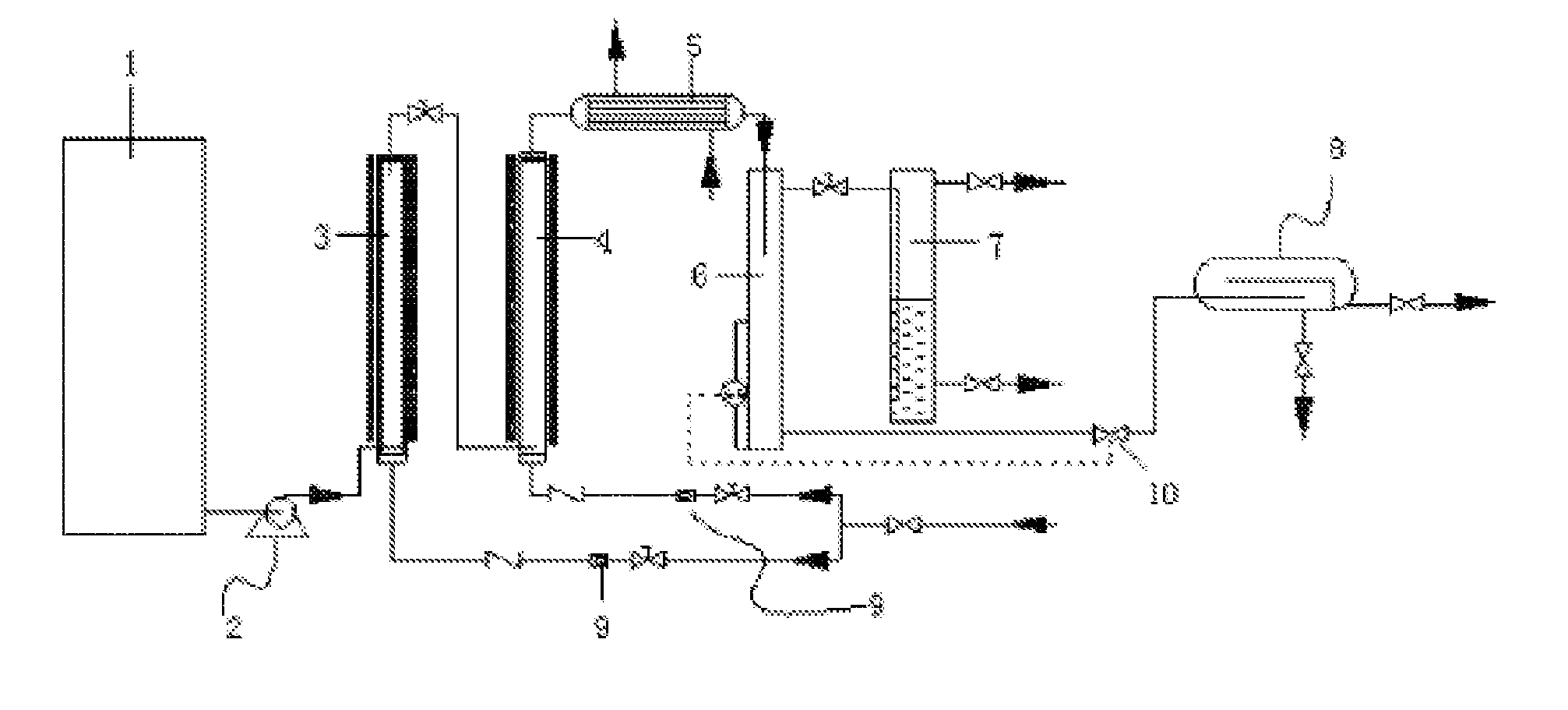

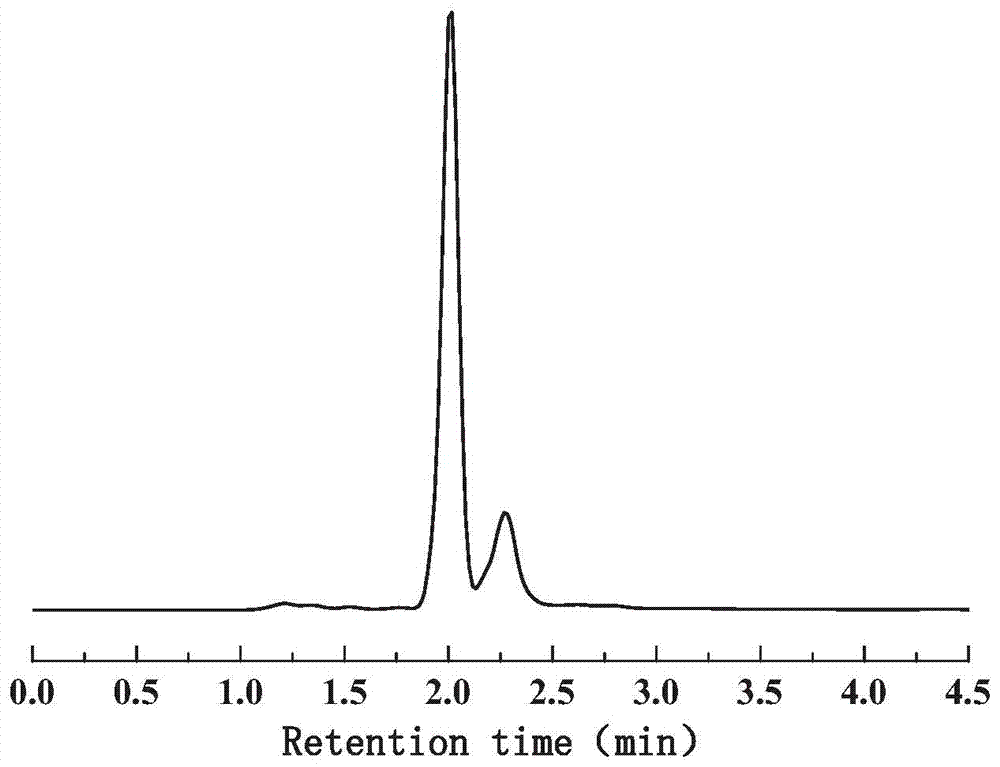

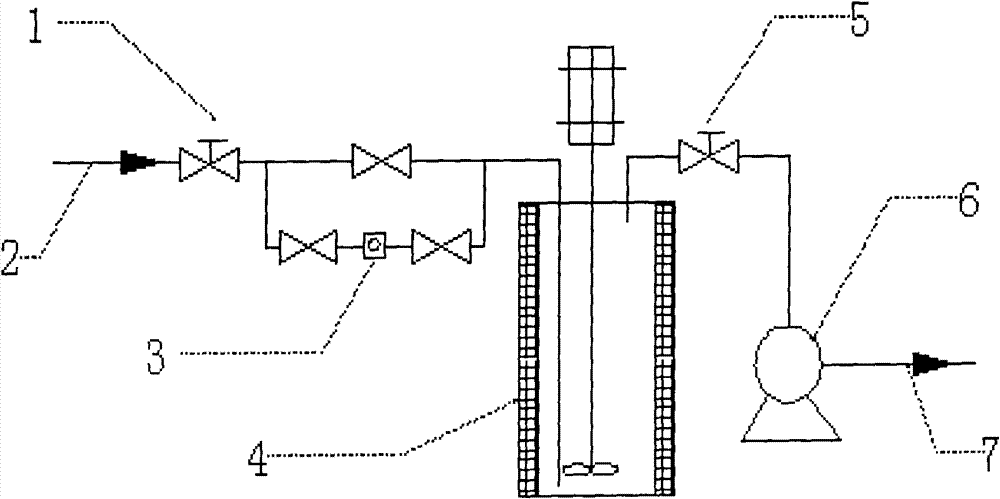

Process for hydrolysed reforming of liquous cellulose biomass to produce bio-gasoline

ActiveUS8562697B2Sufficient supplyReduce acidityLiquid carbonaceous fuelsBio-feedstockAlkaneCellulose

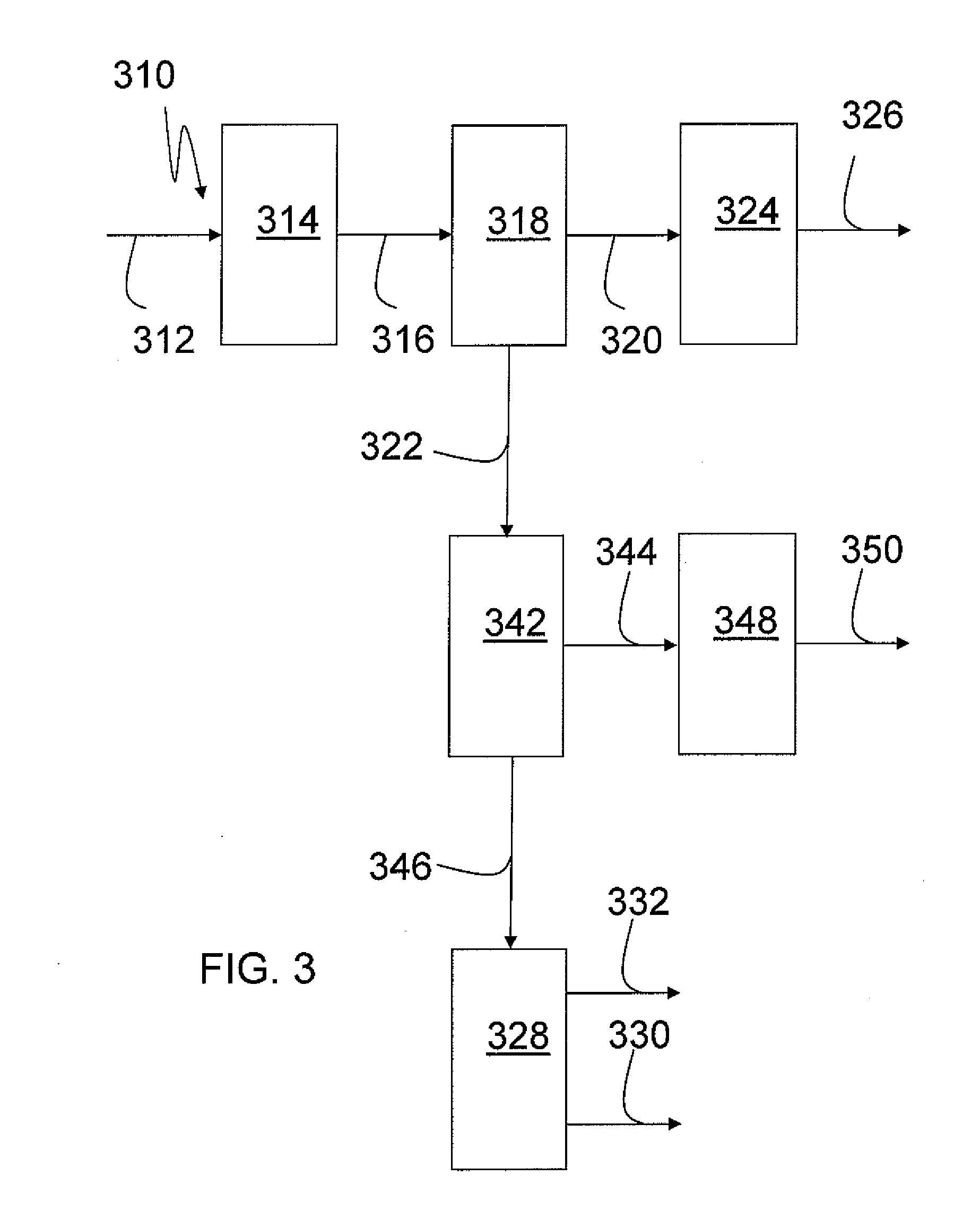

The invention discloses a process for hydrolyzed reforming of the ligneous cellulose biomass to produce bio-gasoline, which directly transfers the hydrolyzed-material liquid obtained from ligneous cellulose biomass through hydrolyzing into aqueous catalytic reforming system, the feed subjects to aqueous catalytic reforming reaction in low-temperature reforming reactor filled with catalyst Ni / SiO2—Al2O3 and in high-temperature reforming reactor filled with catalyst Ni / HZSM-5 in turn, the reactant is condensed and phase-separated: uncondensed bio-gasoline is absorbed by absorption liquid-C6 alkane, condensed liquid is phase-separated through phase-separator, bio-gasoline is obtained in the upper layer of the phase-separator. The invention creates a new process for producing high-quality liquid fuel oil using biomass as feedstock, which can automatically layer and separate, omitting the step of rectifying and purifying product. The feedstock is cheap and broadly available. The product can directly used in the present vehicle-carried engine system, and have prosperous market prospect.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Preparation method of biological gasoline novel energy

InactiveCN102229809ARaw materials are easy to getLow costLiquid hydrocarbon mixture productionBiotechnologyGasoline

Owner:侯受树

Bio-gasoline with additives, preparation method and application of bio-gasoline

The invention discloses a bio-gasoline with additives, a preparation method and an application of the bio-gasoline, and belongs to the technical field of clean fuel. The bio-gasoline comprises methyl alcohol, ferrocene, tween 80, triethanolamine, n-butyl alcohol, oleic acid, ethylene glycol and gasoline. The bio-gasoline is strong in power, low in carbon and cost, environmentally friendly and simple in preparation method, the cost of bio-gasoline per liter is far lower than that of regular gasoline per liter, and engines of gasoline fueled motor vehicles do not need to be reconstructed when the bio-gasoline is used.

Owner:于仰坤

Catalyst for kitchen waste and kitchen waste treatment method

ActiveCN111229197AEasy to understandSolid waste disposalTransportation and packagingAluminium chloridePtru catalyst

The invention relates to a catalyst for kitchen waste. The catalyst is prepared by the following method: fully mixing 15-95 parts by weight of aluminum oxide, 5-32 parts by weight of silicon dioxide,0.01-0.1 part by weight of titanium dioxide, 0.5-10 parts by weight of aluminum chloride, 10-30 parts by weight of zinc oxide, 5-13 parts by weight of water and 3-10 parts by weight of high clay; calcining for 2 to 4 hours in a reducing atmosphere at 200 to 400 DEG C; and cooling, crushing and ball-milling until the specific surface area is 100-400 m < 2 > / g, the pore volume is 0.23-0.50 cm < 2 > / g and the average particle size is less than 200 meshes to obtain the catalyst for kitchen waste. The invention also relates to a kitchen waste treatment method. According to the invention, garbage classification is realized; illegal cooking oil is separated from the kitchen waste; the method comprises the following steps: synthesizing a solid catalyst, introducing illegal cooking oil separated from kitchen waste on site into a high-temperature pressure-resistant reaction kettle by using an electric heating device, a pressure-resistant device, a matched high-vacuum pump and a segmented heatingdevice by using the solid catalyst, and cracking the illegal cooking oil into bio-gasoline and biodiesel.

Owner:广州派安环保科技有限公司

Environmental-friendly clean biogasoline produced from illegal cooking oil and preparation method thereof

InactiveCN106318484AStrong water resistanceAlleviate the shortage of supply and demandLiquid carbonaceous fuelsCooking oilPetroleum

The invention discloses environmental-friendly clean biogasoline produced from illegal cooking oil and a preparation method thereof. The environmental-friendly clean biogasoline is prepared from the following raw materials in parts by weight: 55-70 parts of illegal cooking oil, 15-20 parts of water, 15-20 parts of oleic acid, 0.8-5 parts of a hydrophilc agent, 5-10 parts of an oil control agent and 0.05-0.1 part of a stabilizer. The preparation method comprises the following process steps: pretreating, stirring, regulating the brightness of the oil, standing, curing and the like. According to the invention, the illegal cooking oil serving as a raw material is chemically processed into high-efficiency low-cost biogasoline, so that the illegal cooking oil becomes a favorable industrial resource, waste materials are changed into things of value, the biogasoline is recyclable, the environment can be cleaned, the development of regional economy can be promoted, and the current situation of shortage of supply and demand of regional petroleum is relieved, thus having good economic benefits and great social significance.

Owner:宇航能源集团有限公司

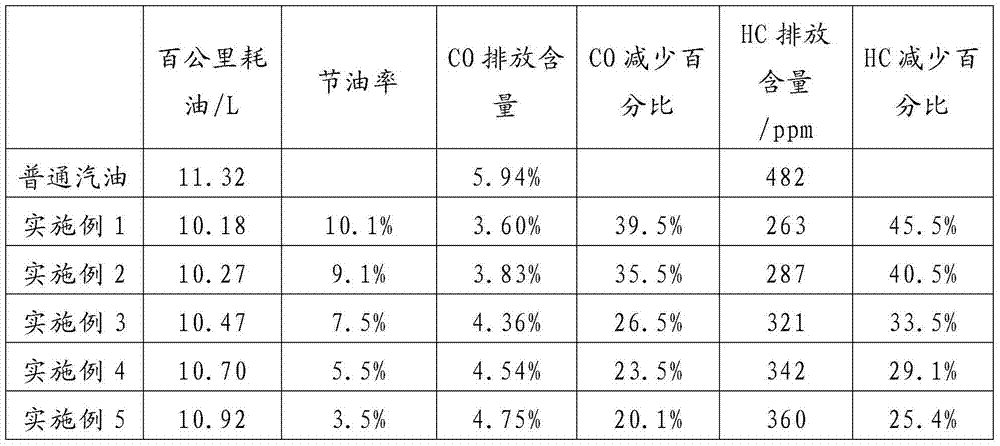

Biogasoline additive and preparation method and application thereof

InactiveCN104745253ANo pollution in the processIncrease isooctane numberLiquid carbonaceous fuelsPollutant emissionsGasoline

The invention relates to a biogasoline additive and its preparation method and application. The invention aims to provide a low-cost biogasoline additive capable of raising isooctane value of gasoline, enhancing anti-detonating quality, reducing pollutant emission, decreasing PM2.5 and improving gasoline combustion efficiency. The biogasoline additive is prepared and applied by the following steps: adding ferment and methyl tert-butyl ether into an alcoholic solvent, heating to 30-40 DEG C, stirring to prepare the biogasoline additive, adding the biogasoline additive which accounts for 0.09-0.5% of the total weight of gasoline into the gasoline, uniformly stirring, and standing at normal temperature for 3-5h for usage.

Owner:EVERFIRST WISEFUND TECH BEIJING

A kind of method that takes biomass as raw material to prepare biogasoline

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

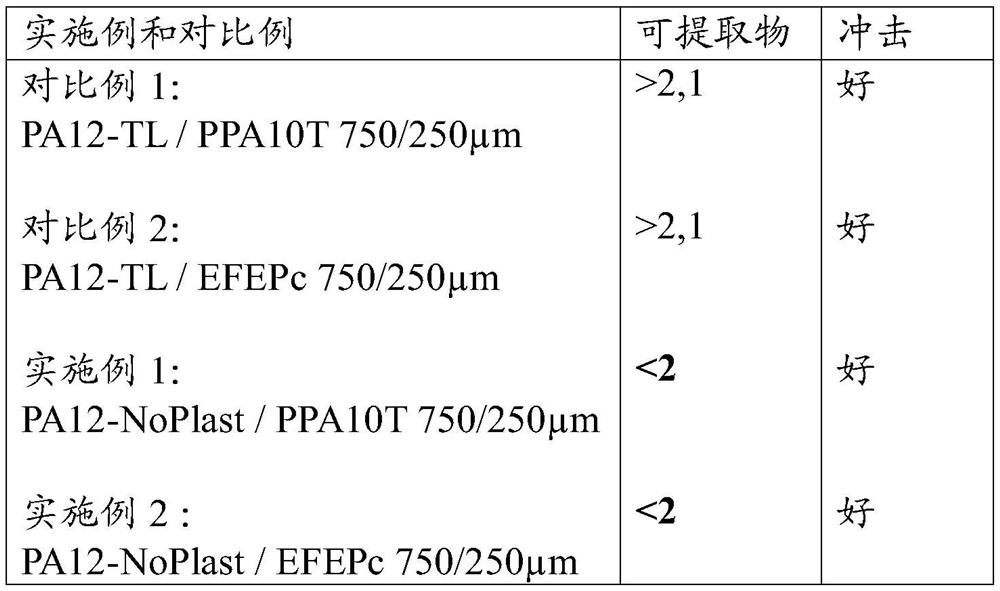

Multilayer tubular structure having improved resistance to extraction in biogasoline and use thereof

The present invention relates to a multilayer tubular structure (MLT) for conveying fluids, in particular gasoline, comprising, from the innermost to the outermost layer, at least one inner barrier layer (1) and at least one outer layer (2) located above the barrier layer, said outer layer (2) or the set of layers (2) and of any other layers located above the barrier layer containing on average 0to 5% of a plasticiser relative to the total weight of the composition of the layer (2), or the set of outer layers located above the barrier layer comprising on average 0 to 5% of a plasticiser, saidouter layer (2) predominantly comprising at least one aliphatic polyamide or a polyamide consisting of more than 75% aliphatic units.

Owner:ARKEMA FRANCE SA

Method of catalyzing sorbitol to synthesize bio-petrol

ActiveCN101550350BIncrease contentIncrease total octaneMolecular sieve catalystsLiquid hydrocarbon mixture productionAlkaneSlurry

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Biological gasoline detergent synergist

InactiveCN111518722AEasy to useAvoid harmBacteriaMicroorganism based processesLyxoseSerratia species

The invention relates to a biological gasoline detergent synergist. The biological gasoline detergent synergist is characterized by containing Rhodococcus erythropolis T7-3 and Serratia marcescens CGMCC 4074. Even shaking is performed before use, and cold storage is the best. A use method of the biological gasoline detergent synergist comprises the following steps: the biological gasoline detergent synergist is mixed with 93# gasoline and a 2% lyxose aqueous solution according to a mass ratio of 1:100:150, a reaction is carried out for 36 h at 50 rpm vortex stirring, standing is performed for2 h or more to wait for oil-water layer separation after the reaction is completed, then a separating funnel is used to collect the oil layer, and the oil product is a modified clean gasoline.

Owner:上海聚茂塑胶制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com