Method for preparing biomass fuel from nanometer materials under catalytic cracking

A biomass fuel and catalytic cracking technology, which is applied in the multi-stage series-connected refining and cracking process treatment, etc., can solve the problems of high production and management costs, poor quality of biodiesel, complicated production processes, etc., and achieves good versatility, The effect of wide application and avoiding process differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

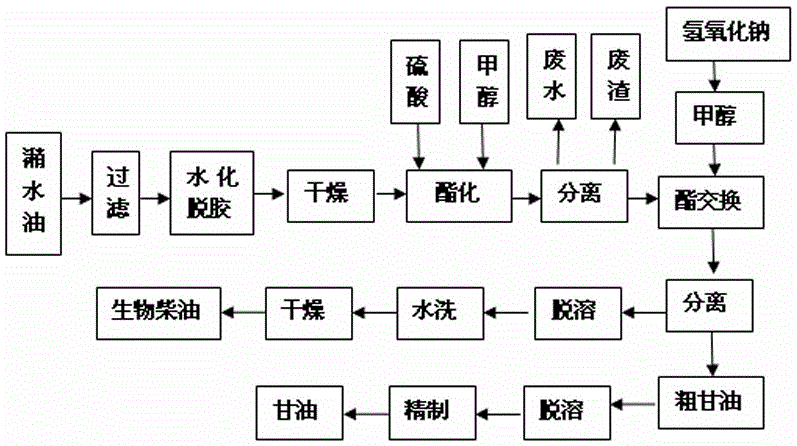

[0036] Such as Figure 4 As shown, the present invention discloses a method for preparing biomass fuel by catalytic cracking of nanomaterials. The biomass fuel includes biodiesel, biogasoline, liquefied gas and fuel gas. The preparation method comprises the following steps:

[0037] Step 1, dehydration and impurity removal treatment, use gutter oil as raw material oil, heat the raw material oil to 280°C, keep it warm for 35 minutes, and then set it aside.

[0038]Step 2, heating and vaporization treatment, the raw oil obtained after dehydration and impurity removal treatment is pumped into the tubular heating furnace, and the heating temperature of the tubular heating furnace is controlled to 420°C to obtain a mixture of grease vapor and heavy oil.

[0039] Step 3. Catalytic cracking treatment. The oil vapor and heavy oil mixture are separated from the heavy oil at the bottom of the catalytic composite tower, and the oil vapor is catalytically cracked into hydrocarbon oil with...

Embodiment 2

[0044] Such as Figure 4 As shown, the present invention discloses a method for preparing biomass fuel by catalytic cracking of nanomaterials. The biomass fuel includes biodiesel, biogasoline, liquefied gas and fuel gas. The preparation method comprises the following steps:

[0045] Step 1. Dehydration and impurity removal treatment. The acidified oil is used as the raw material oil. The raw material oil is heated to 265° C. and then kept for 30 minutes for reaction before being used.

[0046] Step 2, heating and vaporization treatment, the raw oil obtained after dehydration and impurity removal treatment is pumped into the tubular heating furnace, and the heating temperature of the tubular heating furnace is controlled to 420°C to obtain a mixture of grease vapor and heavy oil.

[0047] Step 3. Catalytic cracking treatment. The oil vapor and heavy oil mixture are separated from the heavy oil at the bottom of the catalytic composite tower, and the oil vapor is catalytically cr...

Embodiment 3

[0052] Such as Figure 4 As shown, the present invention discloses a method for preparing biomass fuel by catalytic cracking of nanomaterials. The biomass fuel includes biodiesel, biogasoline, liquefied gas and fuel gas. The preparation method comprises the following steps:

[0053] Step 1, dehydration and impurity removal treatment, use waste animal and vegetable oil as raw material oil, heat the raw material oil to 250°C, keep it warm for 40 minutes, and then set it aside for use.

[0054] Step 2, heating and vaporization treatment, the raw material oil obtained after dehydration and impurity removal treatment is pumped into a tubular heating furnace, and the heating temperature of the tubular heating furnace is controlled to 435°C to obtain a mixture of oil vapor and heavy oil.

[0055] Step 3. Catalytic cracking treatment. The oil vapor and heavy oil mixture are separated from the heavy oil at the bottom of the catalytic composite tower, and the oil vapor is catalytically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com