Method of catalyzing sorbitol to synthesize bio-petrol

A technology for catalyzing sorbitol and synthesizing biology, applied in the field of chemical industry, can solve the problems of low octane number and single distribution of liquid alkane, etc., and achieve the effect of increasing the total octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Catalyst preparation: sieve granular HZSM-5 molecular sieves with 20-100 meshes and a silicon-to-aluminum ratio of 38 as a catalyst carrier, and dry at 100° C. for 10 hours. With 10ml mass percentage concentration is 1% HPtCl 4 The dried molecular sieve sample was impregnated with the aqueous solution for 2 hours and filtered. The filter cake was dried at 120°C for 10 hours, and the dried sample was placed in a muffle furnace, calcined at 550°C for 8 hours, and then reduced in a mixed gas of hydrogen and nitrogen at 550°C for 5 hours to obtain a precious metal content of 1 % of Pt / HZSM-5 catalyst.

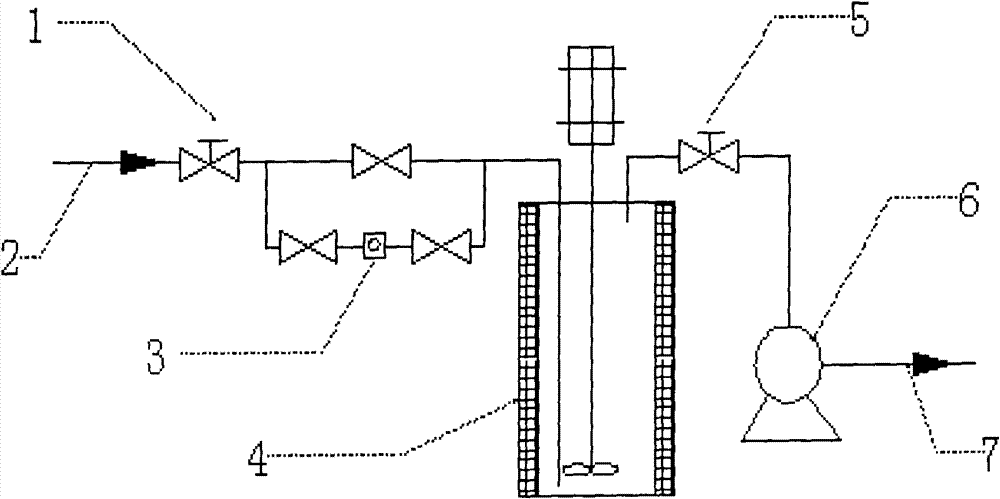

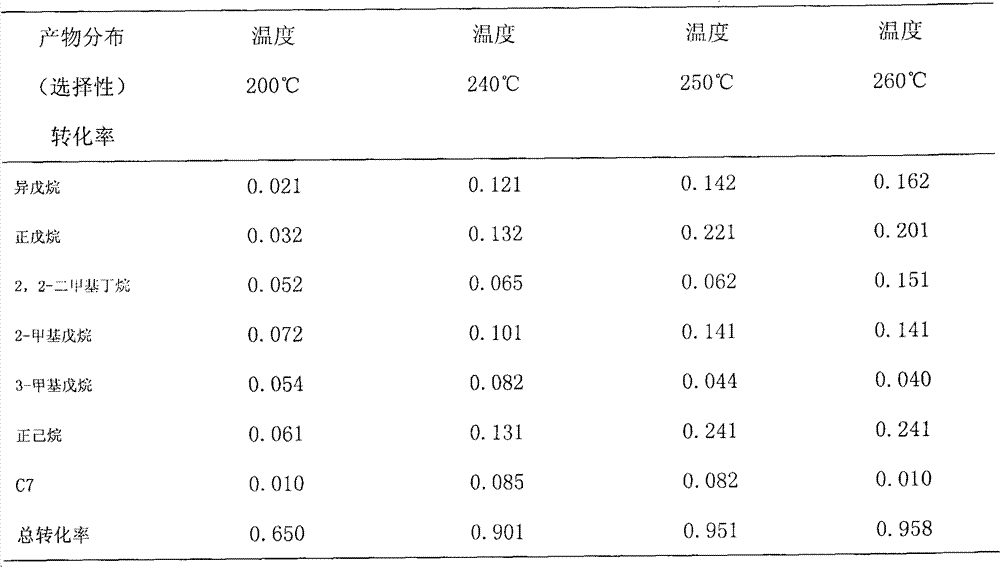

[0025] use figure 1 The reaction setup is shown. Mix 1 gram of the reduced catalyst with 100 grams of sorbitol aqueous solution with a concentration of 5% by mass and add them into the slurry bed. After feeding hydrogen, the reaction starts at a reaction pressure of 5.0 MPa. During the reaction, the hydrogen flow rate was always controlled to be 500ml / min, and the tail ...

Embodiment 2

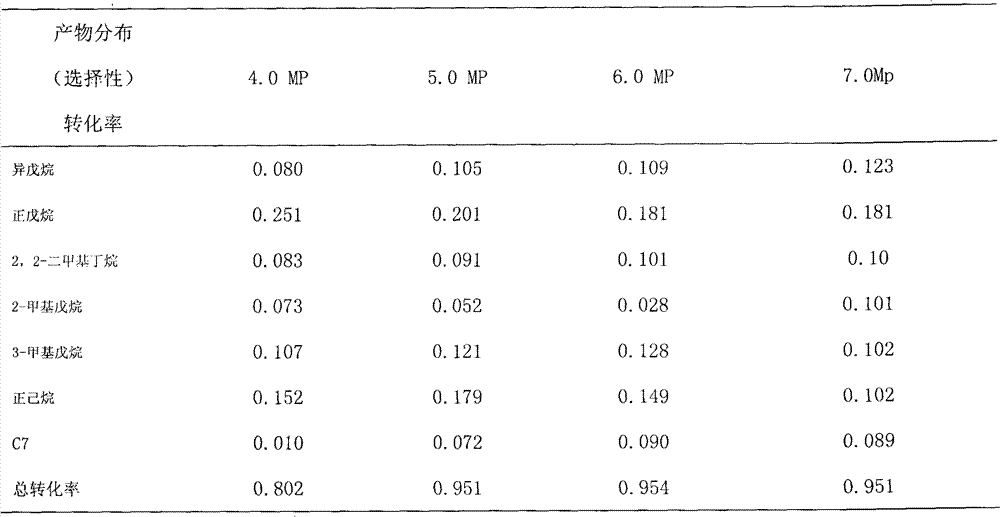

[0029] use figure 1 The reaction device shown is the Pt / HZSM-5 catalyst whose silicon-to-aluminum ratio is 38 in Example 1. Mix 1 gram of the reduced catalyst with 100 grams of sorbitol aqueous solution with a concentration of 5% by mass and add them into the slurry bed. After feeding hydrogen gas, the reaction temperature was fixed at 250° C., and the reaction was started at different reaction pressures. During the reaction, the hydrogen flow rate was always controlled to be 400ml / min, and the tail gas volume was quantified with a wet flow meter. The reaction results are shown in Table 2.

[0030] Table 2 Reaction results of Pt / HZSM-5 under different reaction pressures

[0031]

Embodiment 3

[0033] use figure 1 The reaction device shown is the Pt / HZSM-5 catalyst whose silicon-to-aluminum ratio is 38 in Example 1. The reduced catalyst is mixed with 5% sorbitol aqueous solution and added to the slurry bed. After feeding hydrogen gas, the reaction temperature was fixed at 250° C., and the reaction was started at a reaction pressure of 5.0 MPa. During the reaction, the hydrogen flow rate was always controlled to be 300ml / min, and the tail gas volume was quantified with a wet flow meter. The product distribution and conversion rate at different reaction times were recorded, and the results are shown in Table 3.

[0034] Table 3 Reaction results of Pt / HZSM-5 under different reaction times

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com