Catalyst for preparing C5,C6 light alkane from carbohydrate

A technology for carbohydrates and light alkanes, which is used in the production of hydrocarbons from oxygen-containing organic compounds, the preparation of liquid hydrocarbon mixtures, and metal/metal oxide/metal hydroxide catalysts. problems such as separation loss, industrial application limitations, etc., to achieve good industrial application prospects, easy separation and recovery, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

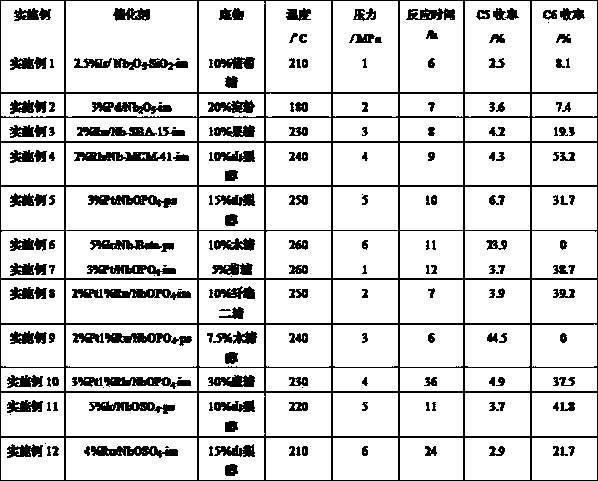

[0020] Catalyst Activity Evaluation in Batch Reactor: Add 10mL of carbohydrate or its derivatives solution and 0.2g of catalysts with different compositions into a high pressure reactor, flush into 1-10 MPa H 2 , and react at 180-290 oC for 6-36 h to prepare C5, C6 light alkanes with high yield. The reaction results are shown in Table 1.

[0021] Table 1

[0022]

Embodiment 13-24

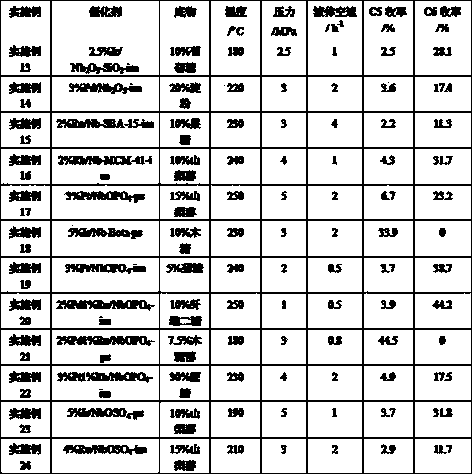

[0024] Activity evaluation in a fixed-bed reactor: 2 g of catalysts with different components were loaded into a fixed-bed reactor, at 300 o C under hydrogen pretreatment for 2 h, then lowered to the operating temperature, and then 5% solution of carbohydrate or its derivatives and hydrogen were introduced into the catalyst bed, first at 110 o After pre-hydrogenation at C, enter the next bed for reaction, the reaction temperature of the next bed is 180-290 ℃, the pressure is 1-10 MPa, and the space velocity of the raw material liquid is 0.1-10 h -1 , and the reaction results are shown in Table 2.

[0025] Table 2

[0026]

Embodiment 25-31

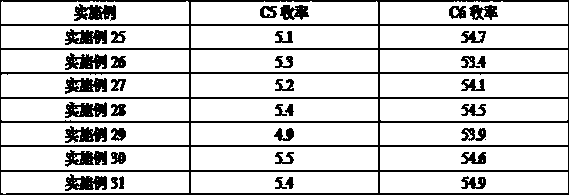

[0028] Catalyst Stability Study: Glucose 1 g and 2%Pd1%Ru / NbOPO 4 -Ps0.3g is added to the reactor, flushed with 4 MPa of hydrogen, and adopts the reaction system of pure water, first at 110 o After prehydrogenation for one hour at C, rise to 230 oC After reacting for 6 h, the reaction solution was analyzed by gas chromatography, quantified by internal standard method, and the catalyst was centrifuged and dried for the next cycle, and so repeated several times. The reaction results are shown in Table 3.

[0029] table 3

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com