A kind of biogasoline and preparation method thereof

A technology of biogasoline and preparation method, which is applied in the petroleum industry, liquid carbon-containing fuel, fermentation, etc., can solve problems such as hidden dangers of food safety, corrosive skin, respiratory tract damage, etc., and achieve less carbon accumulation, low cost, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] A kind of biogasoline, made by mixing potato starch, denatured additives, modifiers, and hydrocarbon alcohol bacteria. The mass percentage of each component is as follows: 90% of potato starch, 5% of denatured additives, modifier 4.5%, 0.5% of alcohol strains, said alcohol strains are alcohol A6, A8, and B11 strains, and their respective mass percentages are 0.125%, 0.125%, and 0.25%.

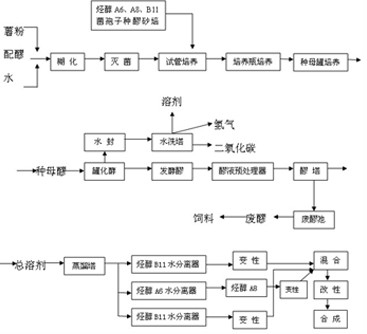

[0079] A preparation method of bio-gasoline, the above-mentioned potato starch, blending mash → gelatinization → sterilization → hydrocarbyl alcohol A6, A8, B11 bacteria test tube culture → culture bottle culture → seed mother tank culture → seed mother mash → tank fermentation → Fermentation mash → mash pretreatment → mash tower → total solvent → distillation tower → hydrocarbon alcohol A6, hydrocarbon alcohol A8, hydrocarbon alcohol B11 → mixing → denaturant, modifying agent to synthesize.

Embodiment 2

[0081] A kind of biogasoline, made by mixing potato starch, denatured additives, modifiers, and hydrocarbon alcohol strains. The mass percentage of each component is: 92% of potato starch, 3% of denatured additives, modifier 4.8%, 0.2% of alcohol strains, said alcohol strains are alcohol A6, A8, and B11 strains, and the respective mass percentages are 0.05%, 0.05%, and 0.1%.

[0082] A preparation method of bio-gasoline, the above-mentioned potato starch, blending mash → gelatinization → sterilization → hydrocarbyl alcohol A6, A8, B11 bacteria test tube culture → culture bottle culture → seed mother tank culture → seed mother mash → tank fermentation → Fermentation mash → mash pretreatment → mash tower → total solvent → distillation tower → hydrocarbon alcohol A6, hydrocarbon alcohol A8, hydrocarbon alcohol B11 → mixing → denaturant, modifying agent to synthesize.

Embodiment 3

[0084] A kind of biogasoline, made by mixing potato starch, denatured additives, modifiers, and hydrocarbon alcohol bacteria. The mass percentage of each component is as follows: 94% of potato starch, 2% of denatured additives, modifier 3%, 1% of alcohol strains, the alcohol strains are alcohol A6, A8, and B11 strains, and the respective mass percentages are 0.25%, 0.25%, and 0.5%.

[0085] A preparation method of bio-gasoline, the above-mentioned potato starch, blending mash → gelatinization → sterilization → hydrocarbyl alcohol A6, A8, B11 bacteria test tube culture → culture bottle culture → seed mother tank culture → seed mother mash → tank fermentation → Fermentation mash → mash pretreatment → mash tower → total solvent → distillation tower → hydrocarbon alcohol A6, hydrocarbon alcohol A8, hydrocarbon alcohol B11 → mixing → denaturant, modifying agent to synthesize.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com