Low-temperature aqueous-phase catalyst for lignin phenol derivative hydrodeoxygenation and preparation method thereof

A phenol derivative, hydrodeoxygenation technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problem of low selectivity of saturated naphthenes, and achieve easy operation and simple preparation process. , the effect of simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

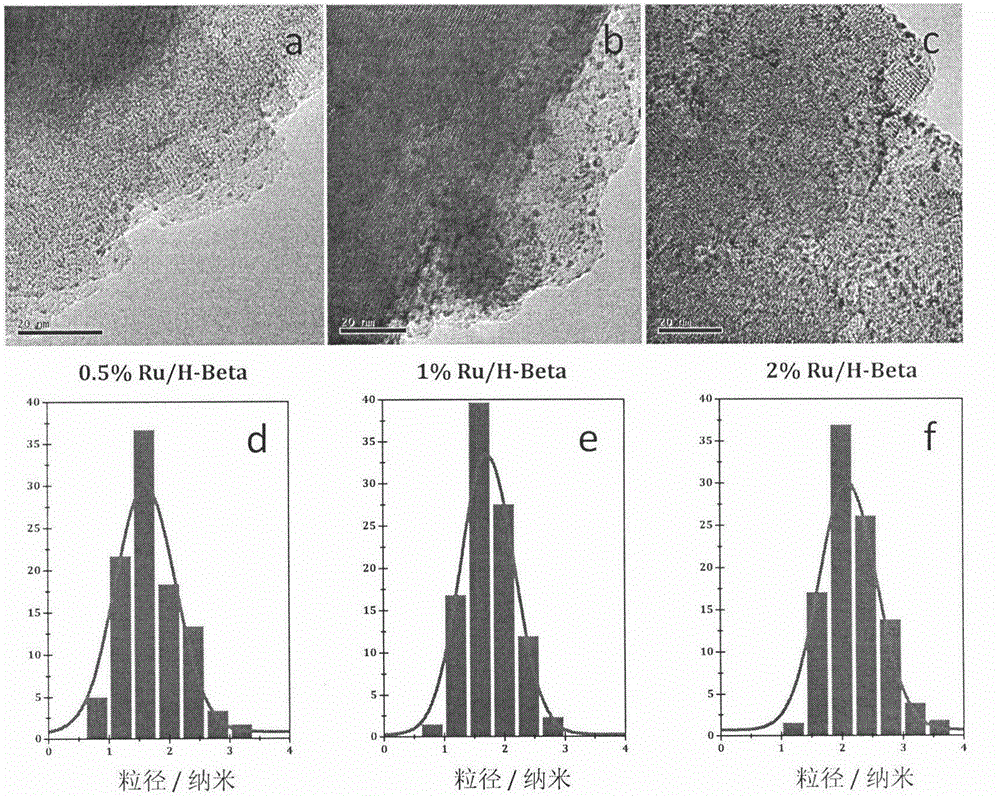

[0023] The preparation method of the 0.5%Ru / Beta catalyst that adopts in the present embodiment is as follows steps:

[0024] 1) A certain amount of Beta molecular sieve raw powder (molar ratio: SiO 2 / Al 2 o 3 =25) placed in a crucible, and calcined in a muffle furnace for 4 hours at a calcining temperature of 550° C. and a heating rate of 5° C. / min. Cool to room temperature and set aside.

[0025] 2) Put 1g of roasted molecular sieve raw powder in a beaker and disperse it into a suspension with 40mL deionized water, add the prepared 1.79mg / mL RuCl 3 Solution 2.8mL, then add a certain amount of water to a total volume of 50mL, continue to stir for 30 minutes. The water was evaporated at 80°C to yield a slurry of solid product. Dry overnight (12 hours) in a constant temperature drying oven at 80°C, and grind into powder.

[0026] 3) Place the quartz boat containing the powder sample in a tube furnace, inject 50 mL / min of hydrogen / argon gas mixture, and reduce at 200° C. ...

Embodiment 2

[0037] In this example, the influence of different supports on the hydrodeoxygenation reaction of diphenyl ether was investigated by using 0.5% Ru catalysts loaded on different supports.

[0038] Table 2 Effect of different acid center supports on the hydrodeoxygenation reaction of diphenyl ether

[0039]

[0040]

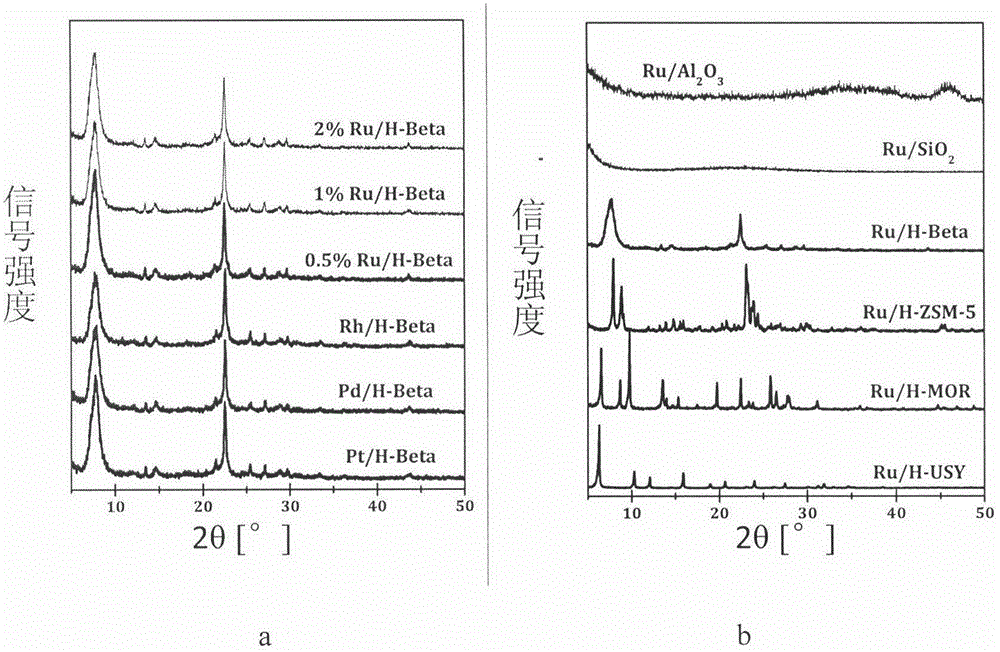

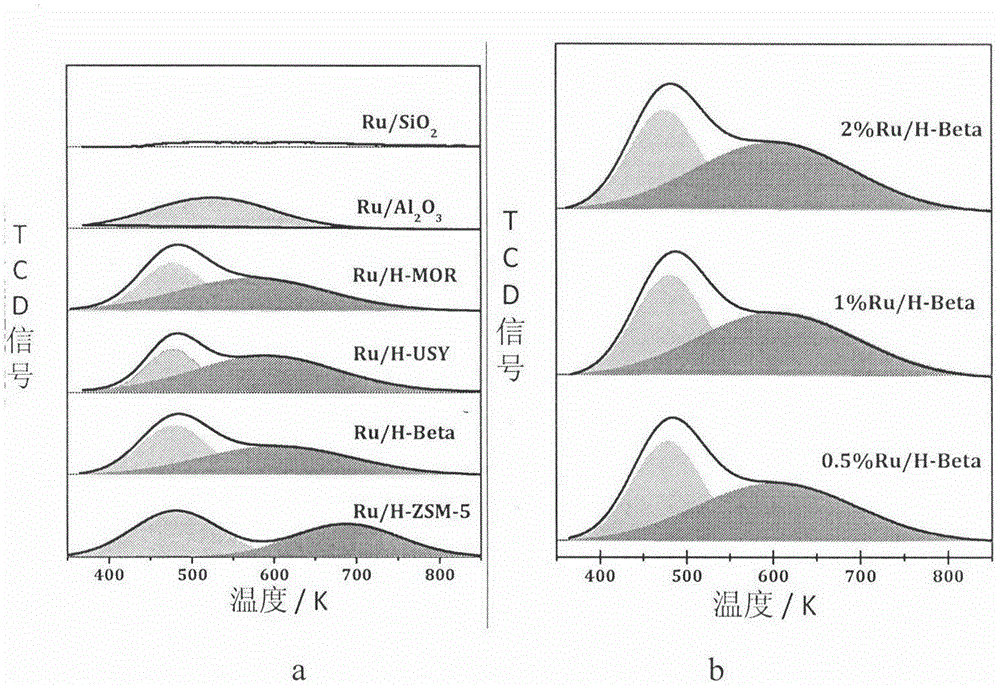

[0041] The catalytic results show that under the conditions of the six catalysts, the substrate conversion rate is not much different, but the selectivity of cyclohexane is the highest for Beta and ZSM-5 molecular sieve carriers, which is different from that of image 3 Middle NH 3 - TPD shows consistent results for high acid strength for both materials. HBeta is an ideal acidic support due to the high selectivity of dicyclohexyl ether, a by-product of overhydrogenation, in Ru / ZSM-5.

Embodiment 3

[0043] In this example, the effect of 0.5% Ru / Beta on the hydrodeoxygenation reaction of diphenyl ether at different temperatures (reaction time: 1 hour).

[0044] Table 3 Effects of different temperatures on the hydrodeoxygenation reaction of diphenyl ether

[0045]

[0046] The catalytic results show that under the reaction condition of 140℃, the reaction rate of dehydration of cyclohexanol to cyclohexane is significantly increased, indicating that this temperature is an ideal reaction temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com