Multilayer tubular structure having improved resistance to extraction in biogasoline and use thereof

A structure and application technology, applied in the field of multi-layer structures, can solve problems such as positioning and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

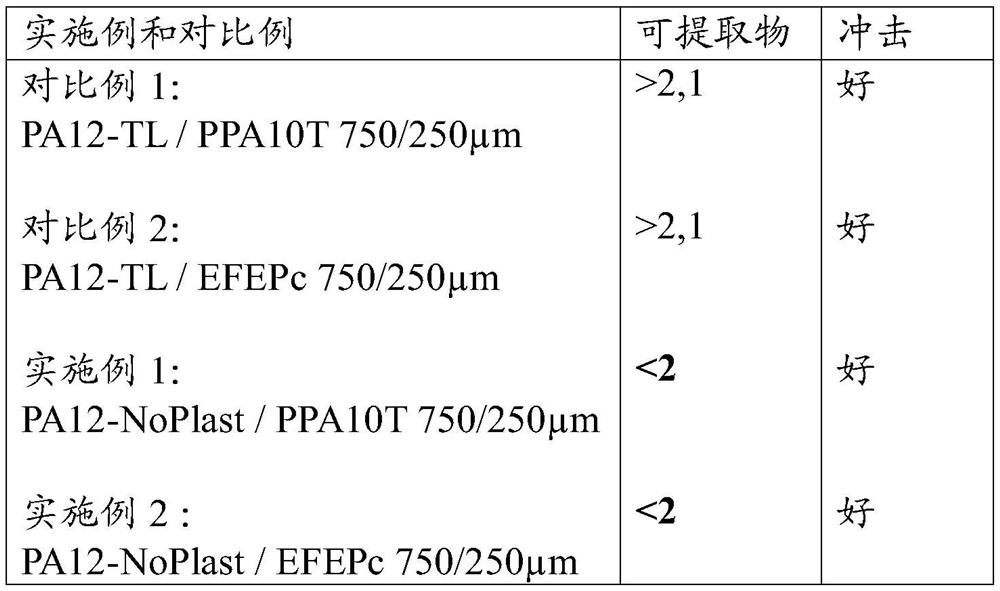

[0158] The invention will now be described in more detail with the aid of the following non-limiting examples.

[0159] The following structures were prepared by extrusion:

[0160] Multilayer tubes are produced by coextrusion. A McNeil multilayer extrusion production (industrial) line equipped with 5 extruders connected with a screw mandrel to a multilayer extrusion head was used.

[0161] The screw used was a single extrusion screw with a screw profile (profile) suitable for polyamides. In addition to 5 extruders and multilayer extrusion heads, the extrusion line includes:

[0162] A die-punch assembly at the end of the coextrusion head; the inner diameter of the die and the outer diameter of the punch as a function of the structure to be made and the material of which it is made, but also as the dimensions and wires of the pipes Selected as a function of velocity;

[0163] • Vacuum tank (tank) with adjustable vacuum. In this tank, water kept substantially at 20° C. is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com