Patents

Literature

70 results about "Biofuel Oils" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

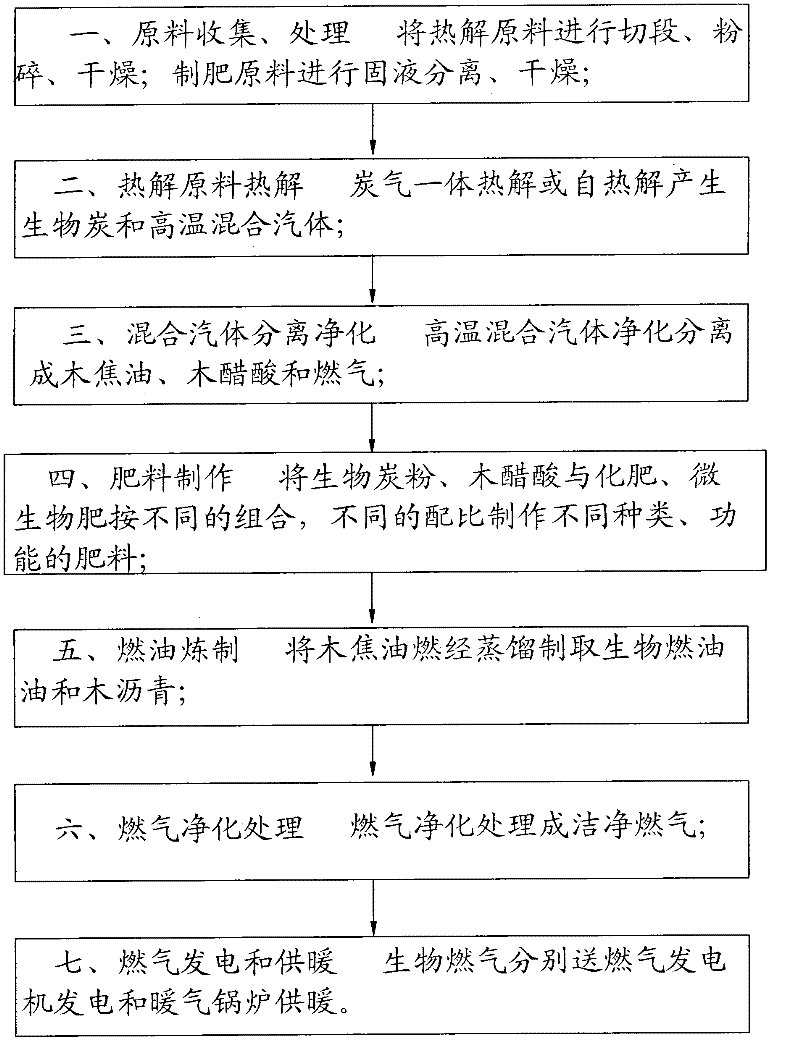

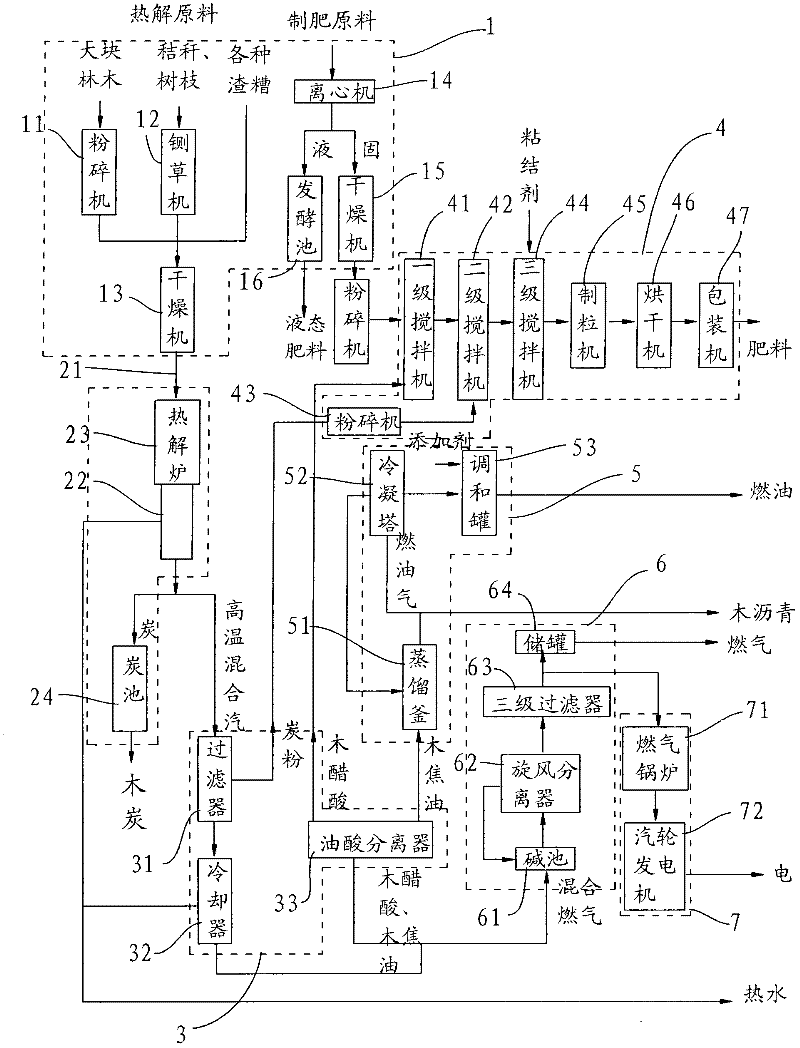

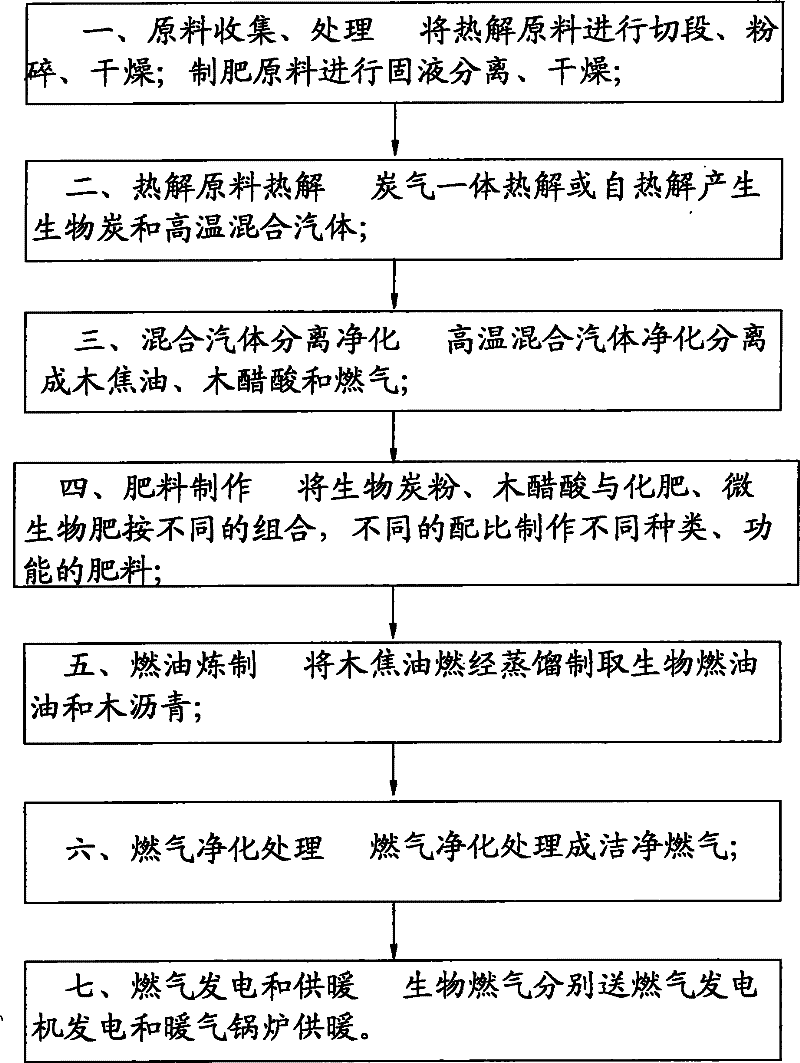

Integrated converting and utilizing co-production method for agricultural waste

InactiveCN102476129AWidely used valueAvoid secondary pollutionSolid waste disposalBiofuelsBiofuelFuel oil

The invention relates to an integrated utilizing technology for agricultural waste and in particular relates to an integrated converting and utilizing co-production method for agricultural waste. The integrated converting and utilizing co-production method comprises the following steps: 1. collecting and processing raw materials; 2. carrying out pyrolysis on the raw materials: generating biochar and high-temperature mixed gas; 3. converting the high-temperature mixed gas: converting the high-temperature mixed gas into wood tar, wood vinegar and fuel gas; 4. manufacturing fertilizers; 5. refining fuel oil: converting the wood tar into biofuel oil and wood pitch; 6. purifying the fuel gas: purifying the fuel gas into clean fuel gas; and 7. converting the fuel gas: respectively sending the biofuel gas into a gas generator, a gas supply pipe network and a heat boiler to covert the biofuel gas into heat energy and electricity energy. The agricultural waste can be converted by multiple levels and are combined to be utilized to obtain straw carbon, fuel gas, heat energy, electricity energy, fertilizers, fuel gas and the like. The use ratio of the agricultural waste reaches 100%. The problem that the agricultural waste is stacked and burnt disorderly can be solved, the pollution problem caused by using chemical fertilizers and pesticides for a long time can be solved, and the problem of utilizing energy, fertilizer and oil in rural areas also can be solved.

Owner:周仁福 +2

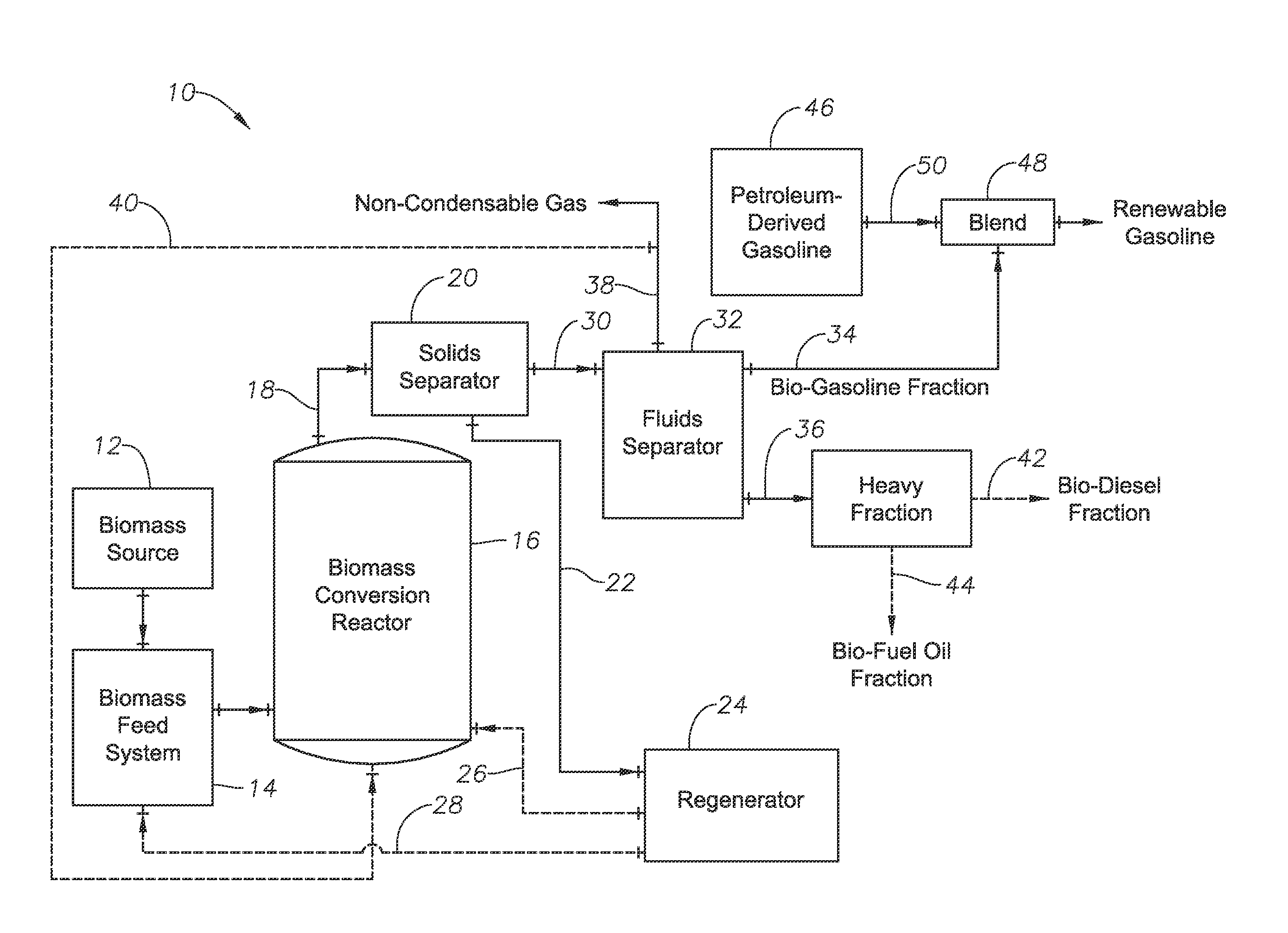

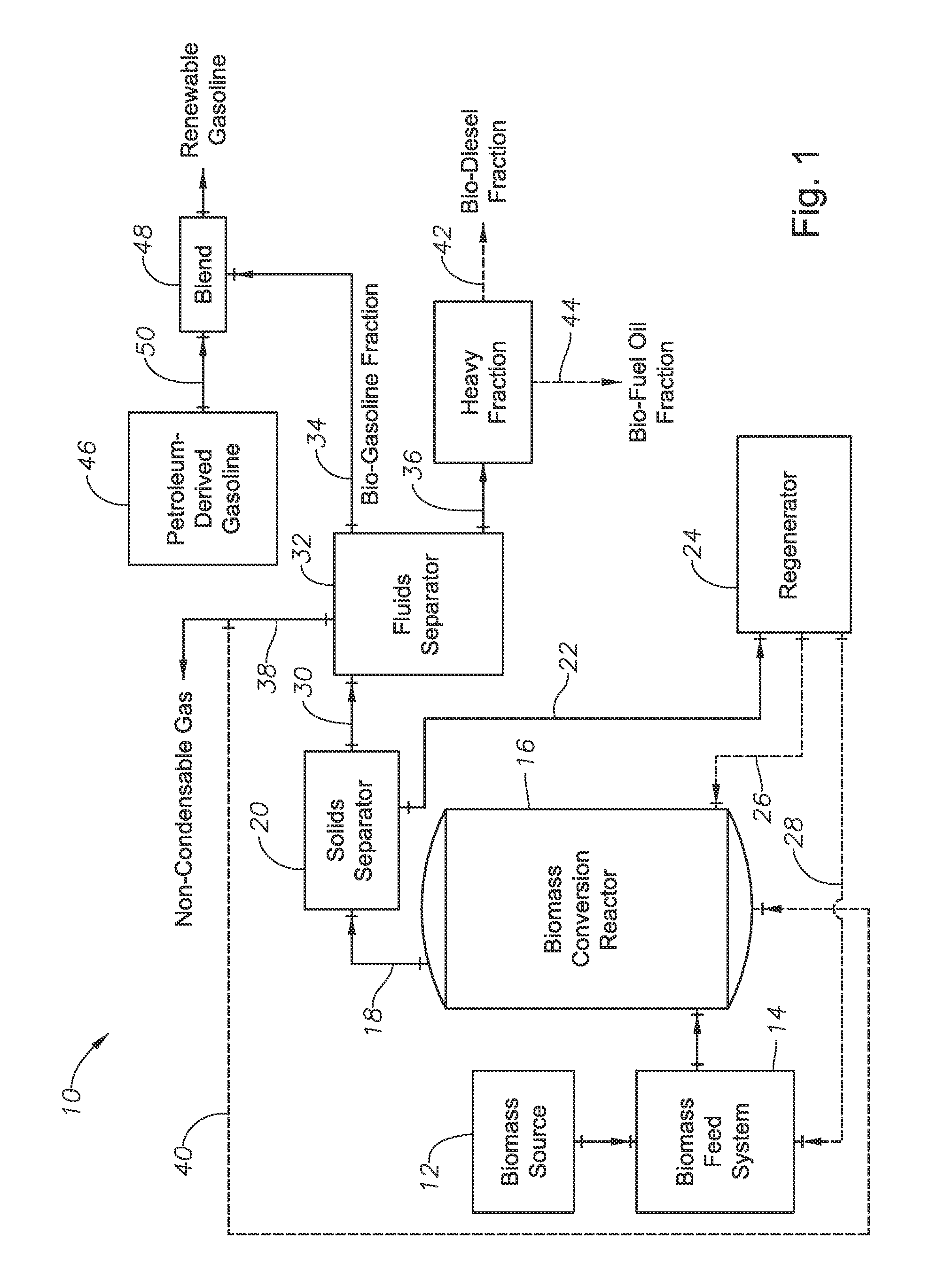

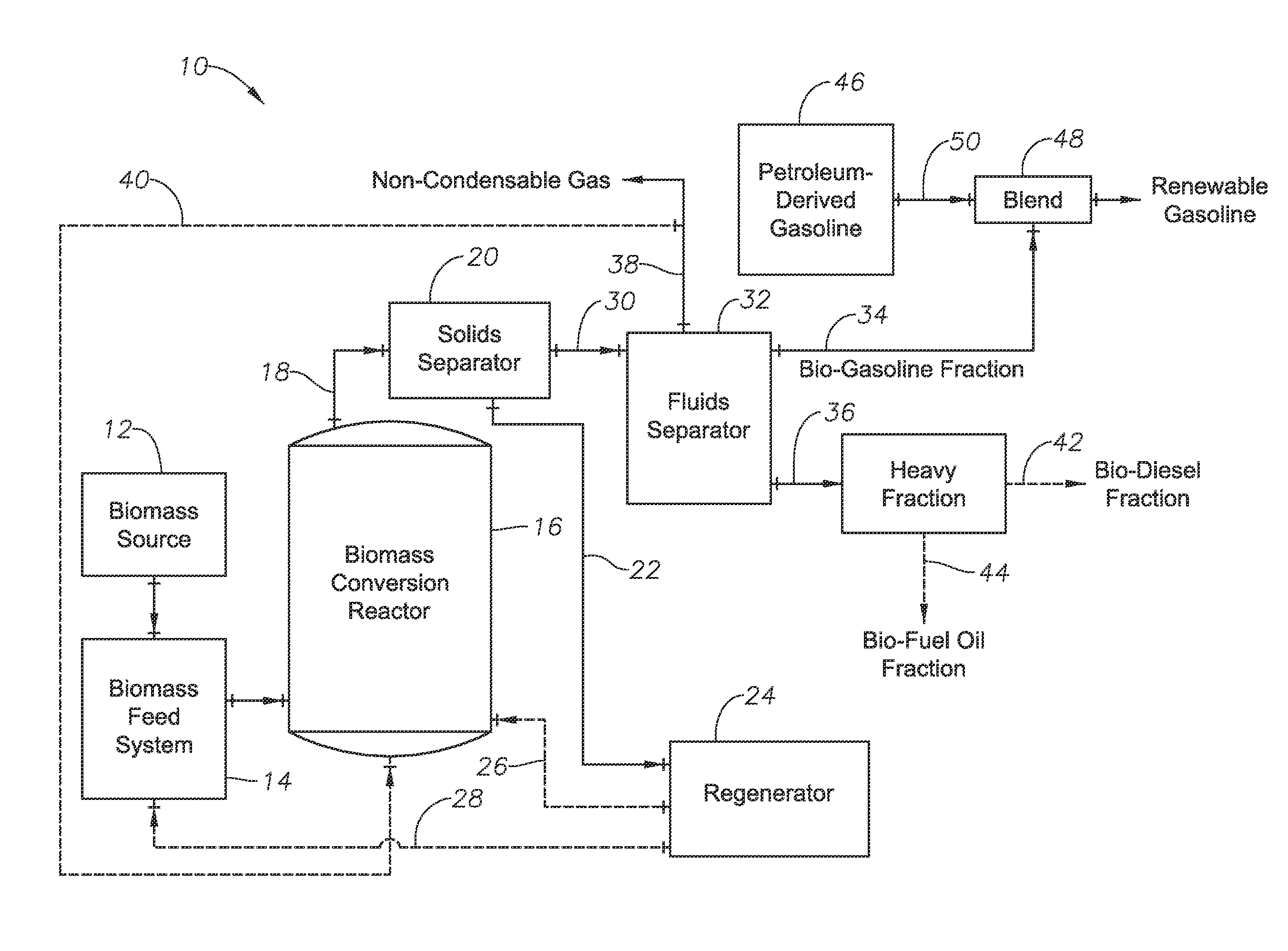

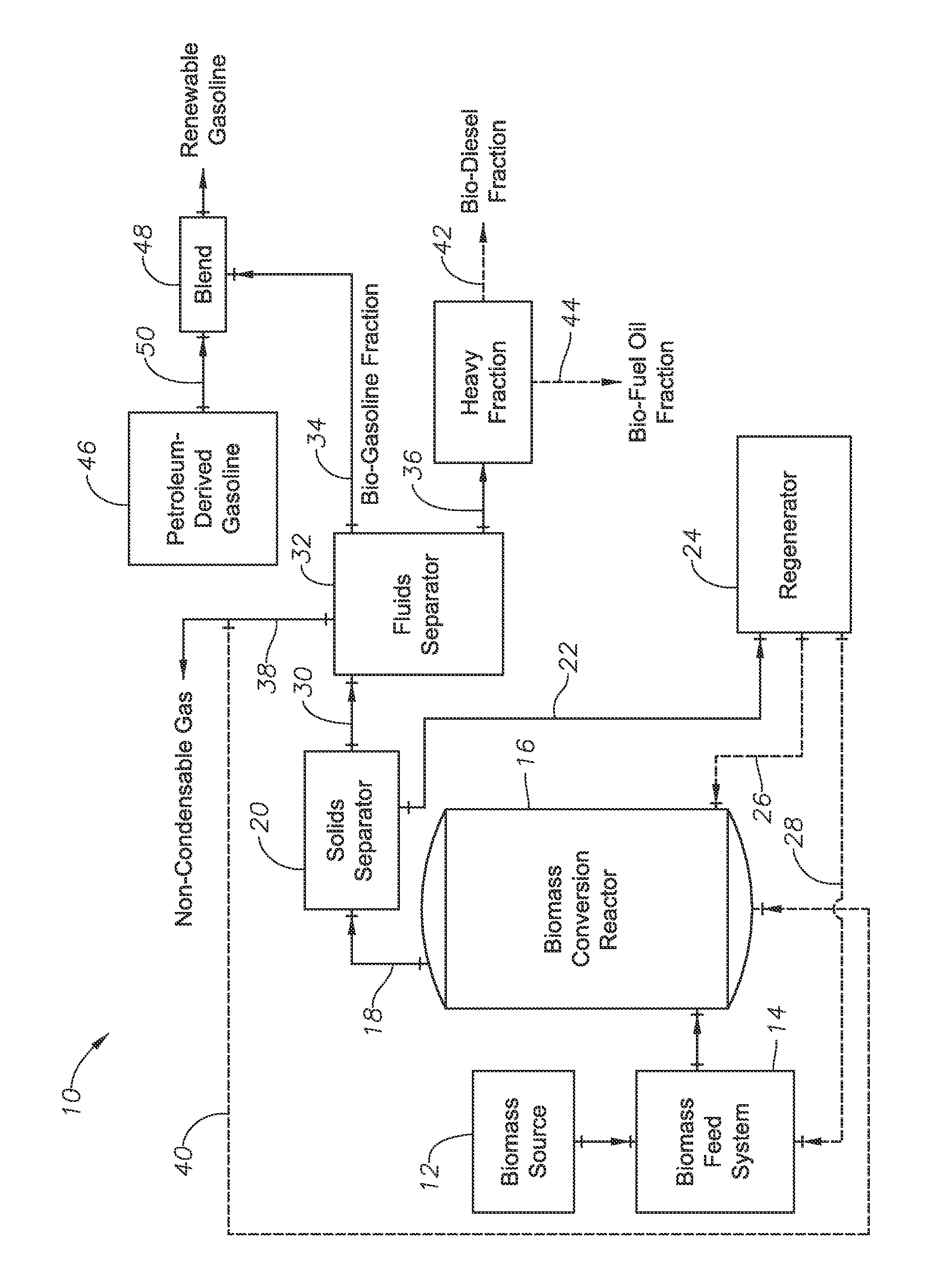

Production of renewable bio-gasoline

A process and system for separating bio-gasoline, bio-diesel and bio-fuel oil fractions from a bio-oil, and for producing a renewable gasoline including at least in part the bio-gasoline fraction, is provided. The process comprises separating bio-oil into a bio-gasoline fraction and a heavy fraction based on their boiling points. At least a portion of the bio-gasoline fraction is directly blended with a petroleum-derived gasoline, without any prior hydrotreatment, to thereby provide a renewable gasoline composition.

Owner:MARD INC

Collection method of oil-containing microalgae

InactiveCN102051332AAccelerated settlementUnicellular algaeLiquid carbonaceous fuelsFlocculationSocial benefits

The invention discloses a collection method of oil-containing microalgae and is characterized in that the method comprises the following steps: a chitosan-Lewis acid flocculant is added into a culture liquid of oil-containing microalgae until the concentration of Lewis acid in the microalgae culture liquid ranges from 3 mg / L to 9 mg / L and the concentration of chitosan in the microalgae culture liquid ranges from 2 mg / L to 30 mg / L; the microalgae culture liquid is rapidly stirred at a rotation speed ranging from 200 rpm to 500 rpm for 1 mintues to 5 mintues and then slowly stirred at a rotation speed ranging from 20 rpm to 70 rpm for 20 mintues to 40 mintues, and sequentially the microalgae culture liquid stands to allow precipitation for 15 mintues to 60 mintues; and the microalgae flocculation body is centrifugally dehydragted under the condition that the rotation speed ranges from 3000 rpm to 5000 rpm. The invention adopts the chitosan-Lewis acid compound flocculant which is easily prepared, can form a compact flocculation body and can increase the overall dehydration rate of the microalgae mud up to over 98%, so as to completely meet the produciton requirements of the biological fuels, achieve the flocculant and catalyst integrated technique, save the cost and have remarkable economic and social benefits.

Owner:OCEAN UNIV OF CHINA

Biofuel oil and preparation thereof

InactiveCN101280231ABoost octaneIncrease cetane numberLiquid carbonaceous fuelsResource savingFuel oil

The invention relates to a method of preparing biological fuel oil based on the compositions of ethanol, methanol, toluene, isopropyl alcohol, surface active agent, ethyl nitrate and ferrocene and the prepared product; the biological fuel oil in the invention has high octane number, high cetane number and low corrosiveness.; the engine which uses the product prepared by the method in the invention has high power and low environmental pollution so that the fuel oil product prepared by the method is the fuel oil which is environmental-friendly and resource saving.

Owner:柏绿山

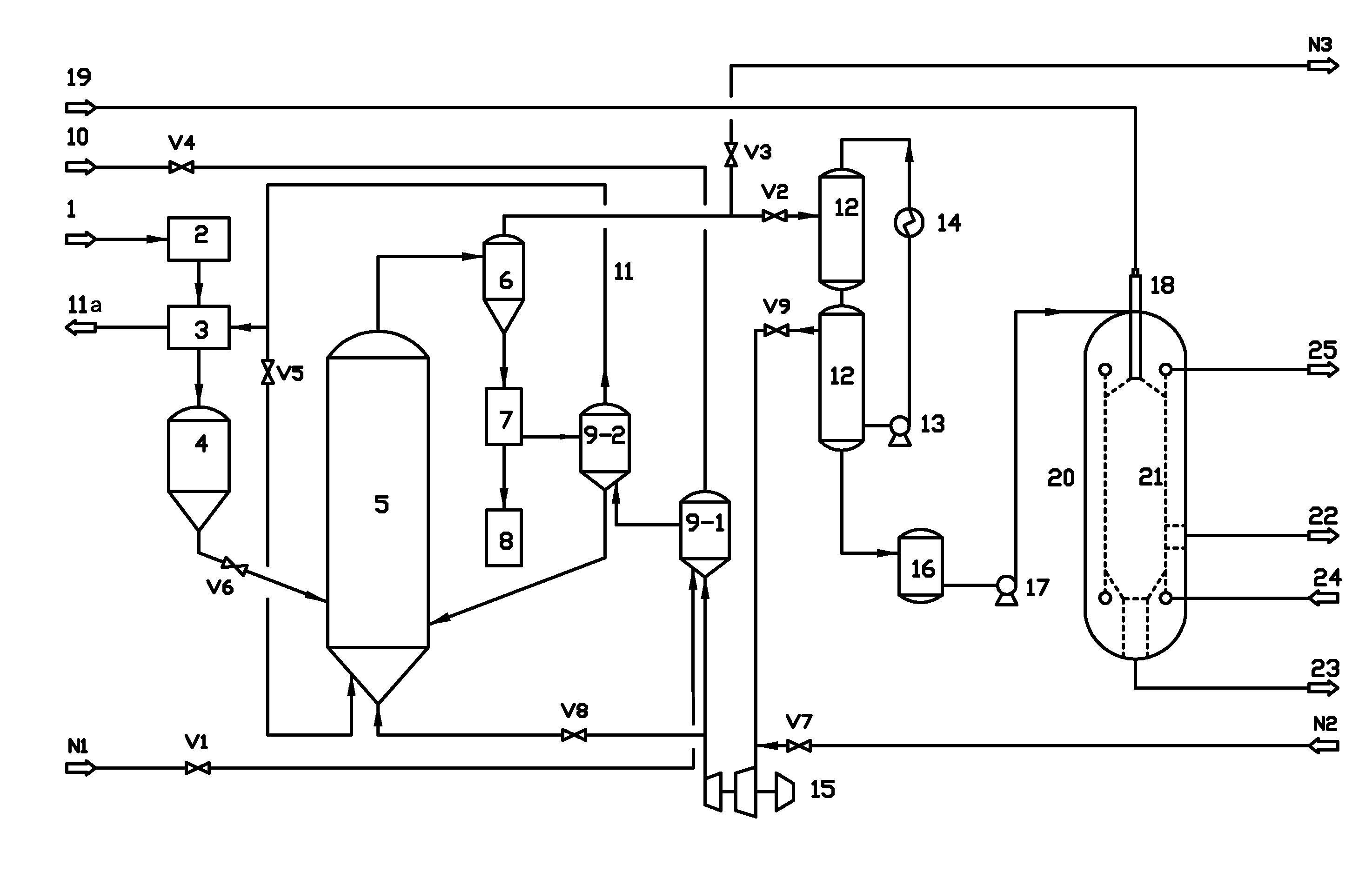

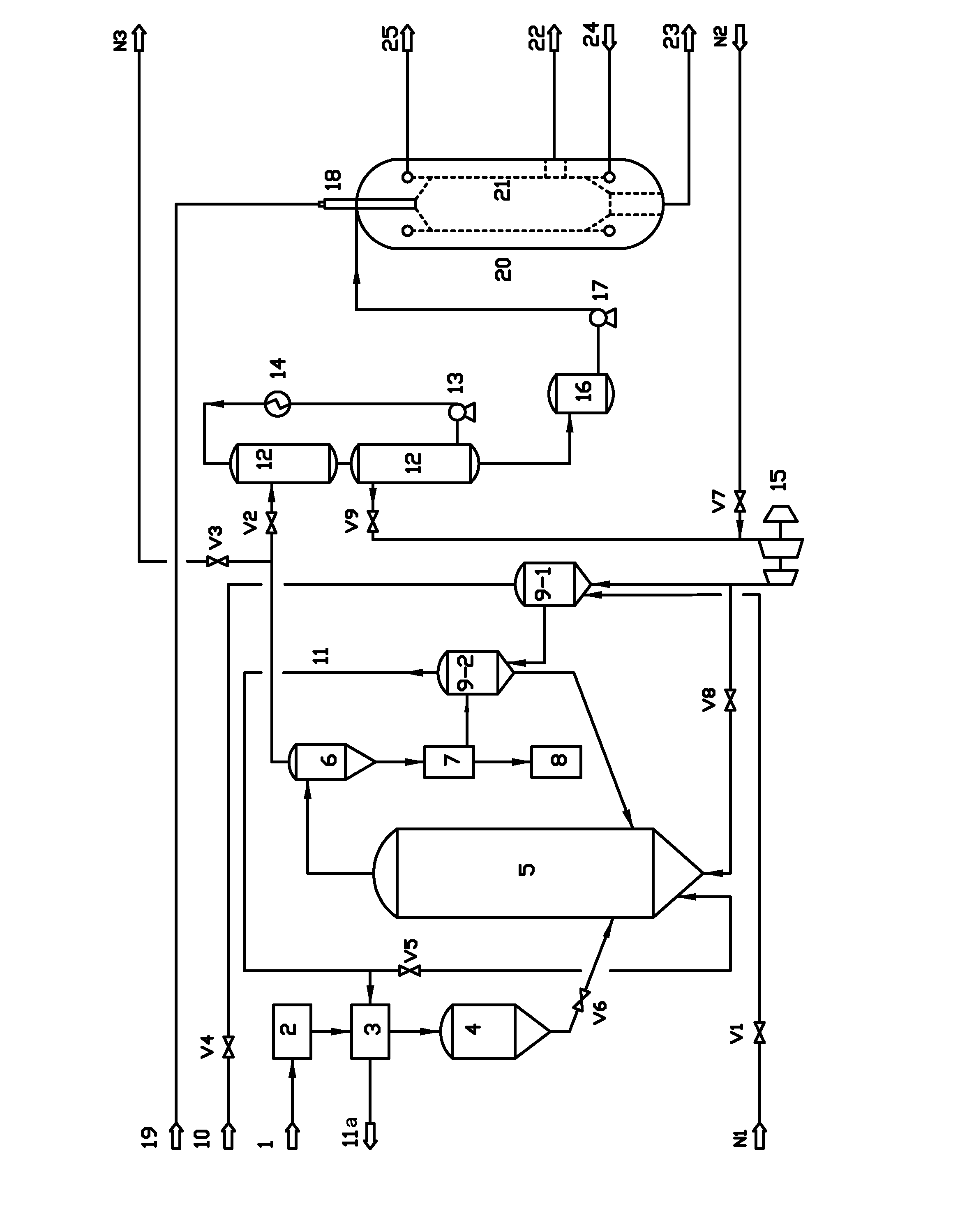

Method and system for producing synthesis gas

InactiveUS20130019529A1Improve efficiencyLow costDirect heating destructive distillationBiofuelsCombustionHeat carrier

A method for producing synthesis gas, including: 1) pre-processing a biomass raw material; 2) pyrolyzing the biomass raw material to yield a pyrolysis gas and a carbon powder; 3) separating the pyrolysis gas from the carbon powder and a solid heat carrier; 4) separating the carbon powder away from the solid heat carrier via a solid-solid separator; 5) conveying the generated pyrolysis gas to a condensate tank for spray condensation, condensing a condensable part in the pyrolysis gas to generate biological fuel oil, pressurizing the generated biological fuel oil by a high pressure oil pump and feeding to a gasification furnace to be gasified; and 6) feeding one part of non-condensable pyrolysis gas to a combustion bed to combust with air, and conveying the other part of the non-condensable pyrolysis gas to the pyrolysis bed as a fluidizing medium.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Production of renewable bio-gasoline

A process and system for separating bio-gasoline, bio-diesel and bio-fuel oil fractions from a bio-oil, and for producing a renewable gasoline including at least in part the bio-gasoline fraction, is provided. The process comprises separating bio-oil into a bio-gasoline fraction and a heavy fraction based on their boiling points. At least a portion of the bio-gasoline fraction is directly blended with a petroleum-derived gasoline, without any prior hydrotreatment, to thereby provide a renewable gasoline composition.

Owner:MARD INC

Fuel oil blending additive and preparation method thereof

InactiveCN103509615APowerfulHigh calorific valueLiquid carbonaceous fuelsFuel additivesFuel oilCold filter plugging point

The invention provides an additive for blending fuel oil. The additive comprises an emulsifier formed by complexing a Span-series emulsifier and a Tween-series (or OP-10) emulsifier, a pH value buffering pair formed by combination of sodium petroleum sulfonate and barium petroleum sulfonate, tricresyl phosphate, isooctyl nitrate, a co-emulsifying dispersing agent, an antioxidant, isobutyl alcohol and an organic solvent. The additive is prepared according to certain content and a certain preparation method. The additive can be used for blending methanol, methanol-oleic acid mixture, and other methanol modified complex into a biological fuel oil, and can be used for further blending biodiesel. The blended biological fuel oil and the biodiesel have the advantages of high cetane number, high flash point, low pour point, low cold filter plugging point, low corrosivity, low emission, and low cost.

Owner:刘粤荣 +1

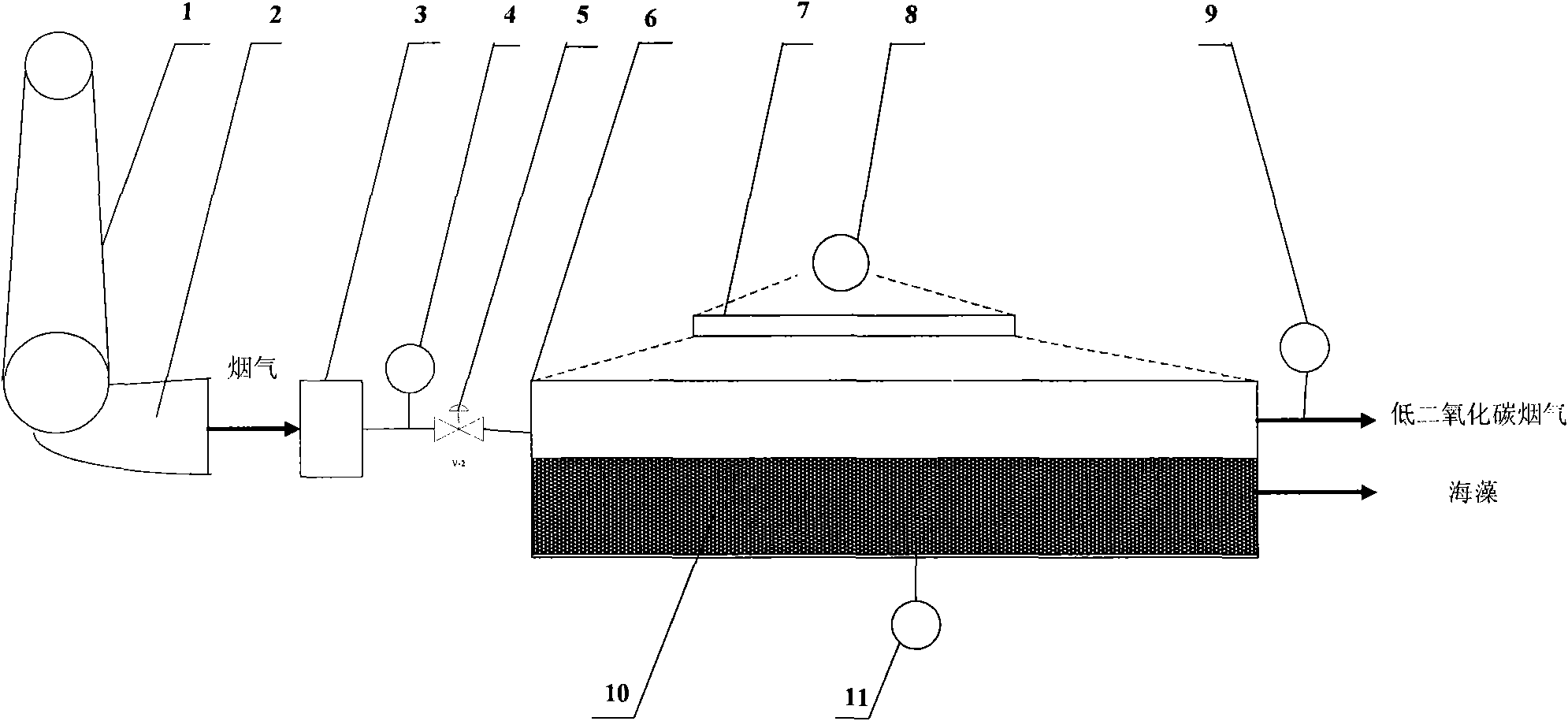

Method for preparing biofuel by using flue gases as raw materials

InactiveCN101525551APromote growthIncrease productionClimate change adaptationLiquid carbonaceous fuelsBiodieselIron plant

The invention belongs to the technical field of greenhouse gas emission reduction and biofuels and relates to a method for preparing a biofuel by using fuel gases as raw materials. Fuel gases emitted in large volume from power plants, steel plants and the like are used as the raw materials for producing the biofuel; in a specially designed bioreactor with light irradiation, rich carbon dioxide in the fuel gases are absorbed by seaweed through photosynthesis, and culture fluid is added at the same time to allow the seaweed to grow rapidly; and the produced seaweed can be converted to biodiesel and other fuels. The technology not only achieves the aims of dramatically reducing the carbon dioxide in the fuel gases and rapidly culturing a large amount of seaweed at low cost, but also solves the problems of greenhouse gas emission reduction and biofuel shortage. The method can be used as greenhouse gas emission reduction technology and used for producing biofuel oil containing seaweed as a by-product to obtain a biofuel for producing biodiesel at the same time in industries continuously emitting carbon dioxide containing flue gases, such as power plants, iron plants, and building material and cement industries.

Owner:饶文涛 +1

Process of preparing biofuel oil and fuel gas with half-dried biomass

The present invention belongs to the field of comprehensive biomass utilizing technology, and is especially process of preparing biofuel oil and fuel gas with half-dried biomass. By means of half-drying process at relatively low temperature (300 600 deg.c), biomass is heat converted into biofuel oil and fuel gas without need of introducing gasifying medium and preheating gas. In the product, the obtained biofuel oil has heat value of 30-46 MJ / kg and oxygen content less than 6 %.

Owner:北京瑞增兰宇新能源科技有限公司

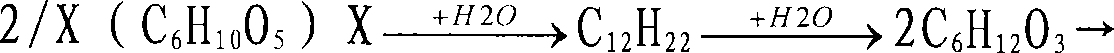

Method for preparing fuel oil biological butanol by using cassava as raw material

InactiveCN101165188ALow vapor pressureImprove fuel efficiencyBiofuelsMicroorganism based processesBiofuel OilsFuel oil

The process of preparing fuel oil butanol with cassava material includes the steps of mixing slurry with crushed cassava or cassava starch, adding acid or alkali to soak and to eliminate impurity, adding S1010 to catalyze reaction, cooling, inoculating CL.a-b Np-1 spawn to ferment to obtain mixed liquid, fractionating to obtain coarse fuel oil butanol product, and treating with QR-W absorbent to obtain refined fuel oil butanol product. The refined fuel oil butanol product may be added with QR-E modifier to obtain qualified fuel oil butanol. The process is simple and low in cost, and the present invention provides one new way for producing biofuel oil and utilizing cassava resource.

Owner:王燕飞

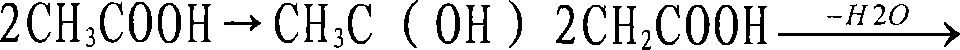

Method for harmless resourceful treatment of antibiotic mushroom dregs

ActiveCN107008734ARealize harmless treatmentRealize resource processingCarbon compoundsSolid waste disposalBound waterCarbonization

The invention discloses a method for harmless resourceful treatment of antibiotic mushroom dregs, and belongs to the technical field of solid waste treatment. Firstly, a mushroom dreg cell thin film structure is destroyed through composite enzymatic hydrolysis and is initially fractured; then liquid nitrogen frozen is carried out to enable water in cells to freeze and swell instantly, the cells are supported to be broken, bound water in the mushroom dregs and the water in the cells are released and desorbed, the mushroom dregs obtained after dehydration are subject to anaerobic fermentation, marsh gas obtained after fermentation is collected to provide pyrolysis energy sources, the mushroom dregs obtained after fermentation are subject to pyrolysis coking through a hydrothermal method, and porous coking objects are obtained; and carbonization and excitation are carried out to prepare activated carbon, hydro-thermal treatment liquid is subject to distilling to removal water, then biological fuel oil is prepared, and harmless resourceful treatment of the antibiotic mushroom dregs can be carried out. According to the treatment method, needed energy consumption is low, the treatment period is short, resource reutilization is achieved, antibiotic residues and secondary pollution are avoided, and the wide application prospect is achieved.

Owner:CHENGDU DEFEI ENVIRONMENTAL ENG CO LTD

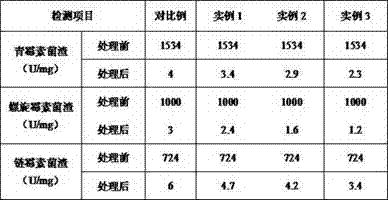

Comprehensive utilization method of vinasse

InactiveCN103849414AIncrease volume fractionHigh calorific valueSilicaWaste processingActivated carbonHydrogen

The invention relates to a comprehensive utilization method of vinasse, and aims at mainly solving the technical problem that a novel method for processing vinasse is provided. The comprehensive utilization method of the vinasse disclosed by the invention mainly comprises the following steps: taking dried vinasse, crushing, and adding a catalyst to split, so as to obtain cracked steam and cracked residue; condensing the cracked steam to obtain bio-oil and a pyrolysis gas; adding a dehydrating agent to the bio-oil, and dehydrating to obtain biofuel oil. The bio-oil also can be used as a source of a series of important chemical raw materials; the pyrolysis gas is a combustible gas with a high calorific value which is obtained after carbon dioxide is removed; the pyrolysis gas also can be used as a source for obtaining hydrogen; the cracked residue can be directly used as activated carbon, a catalyst or a vector or metal components in the cracked residue are recovered. In addition, the residual residues are obtained, can be used as the activated carbon, and also can be used as fuel, so as to obtain white carbon black by combustion.

Owner:YIBIN UNIV

Oil-containing microalgae pressure catalytic oil refining technology

InactiveCN101984025AImprove stabilityNo precipitationLiquid carbonaceous fuelsLiquid productPtru catalyst

The invention discloses an oil-containing microalgae pressure catalytic oil refining technology, comprising the following steps: directly putting the wet microalgae into a high pressure reactor, and adding a certain amount of organic solvent and Lewis acid catalyst into the reactor; inflating the CO2 of 2 to 4 MPa into the reactor, stirring and heating to the temperature of 300 to 450 DEG C to react for 30 to 60 minutes; and cooling to the room temperature to obtain a raw product, and separating to obtain a liquid product; removing part of the organic solvent and most of the water, and addinga microemulsification assistant to obtain the micro emulsification biofuel oil. In the invention, the wet microalgae is used as the raw material, thereby avoiding the defect of large consumption of the energy in the drying of the oil-containing microalgae. The micro emulsification biofuel oil produced has good stability, no layering, no sediment, high temperature resistance, easy storage, high calorific value, sufficient burning and less ash content, can be used to replace the domestic fuel and part of the industrial fuel, and has wide application field.

Owner:OCEAN UNIV OF CHINA

Method for hydrofinishing biological crude oil by using high temperature gas cooled reactor

ActiveCN105602612AReduce economic costsEmission reductionRefining to eliminate hetero atomsNuclear reactor coreThermochemical cycle

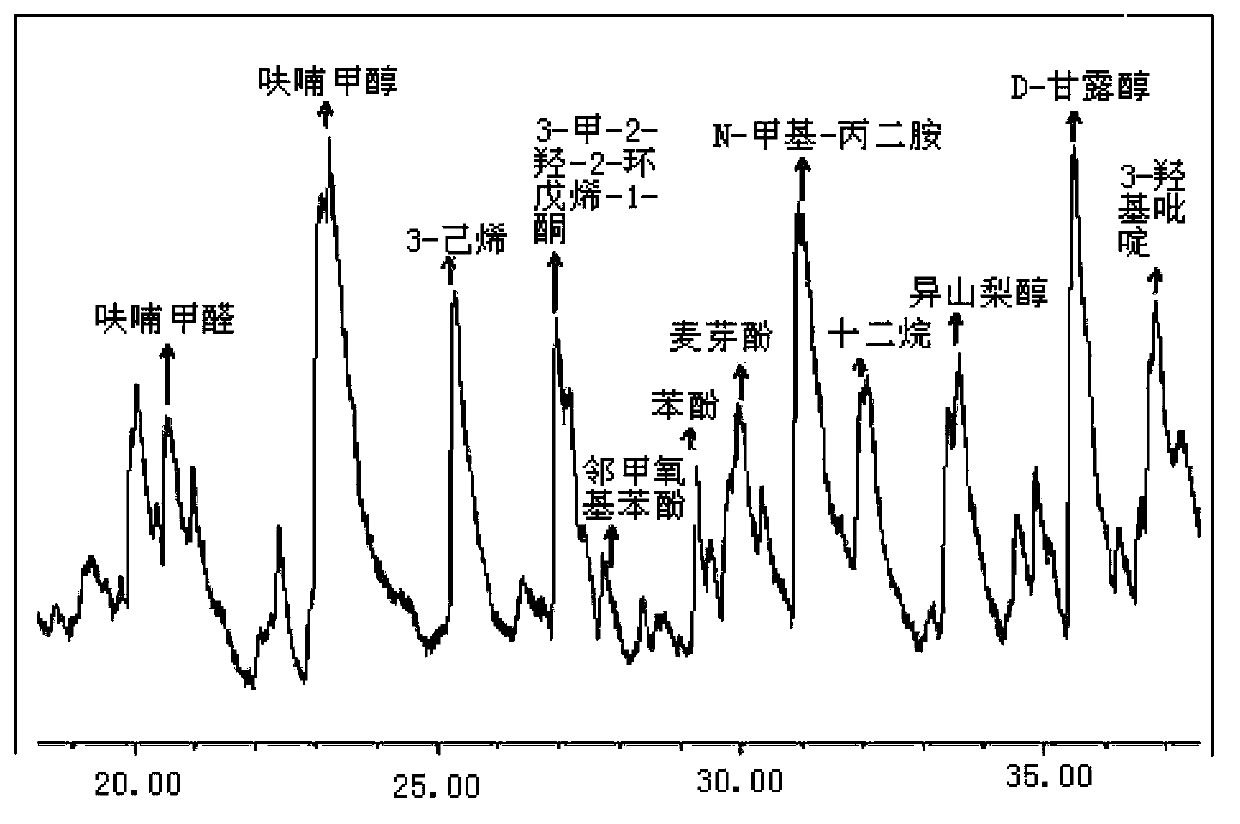

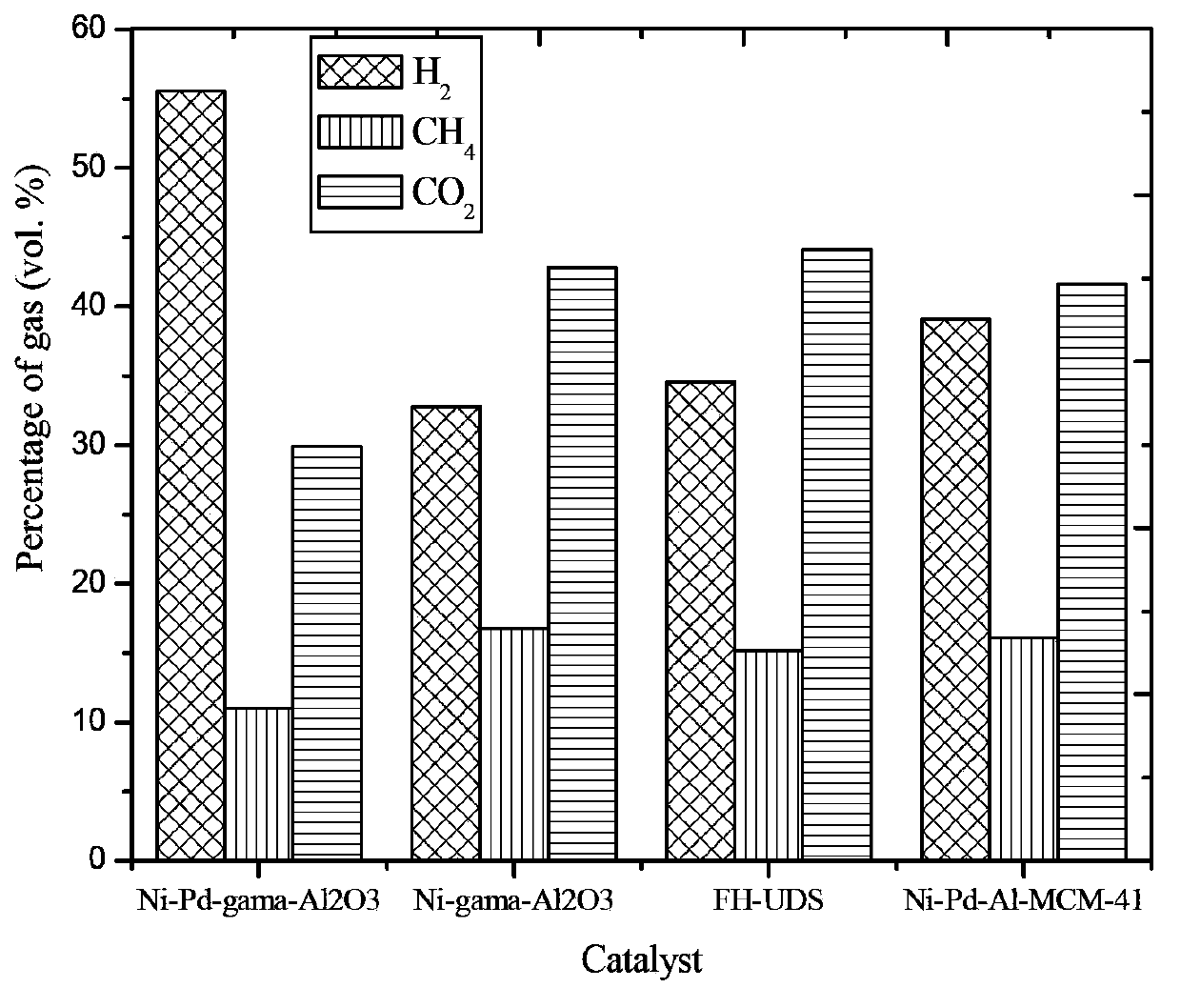

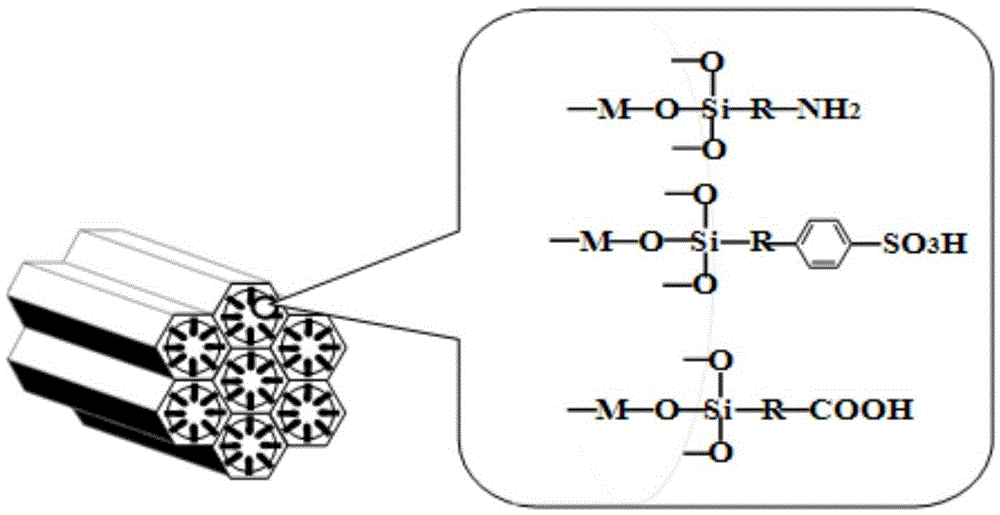

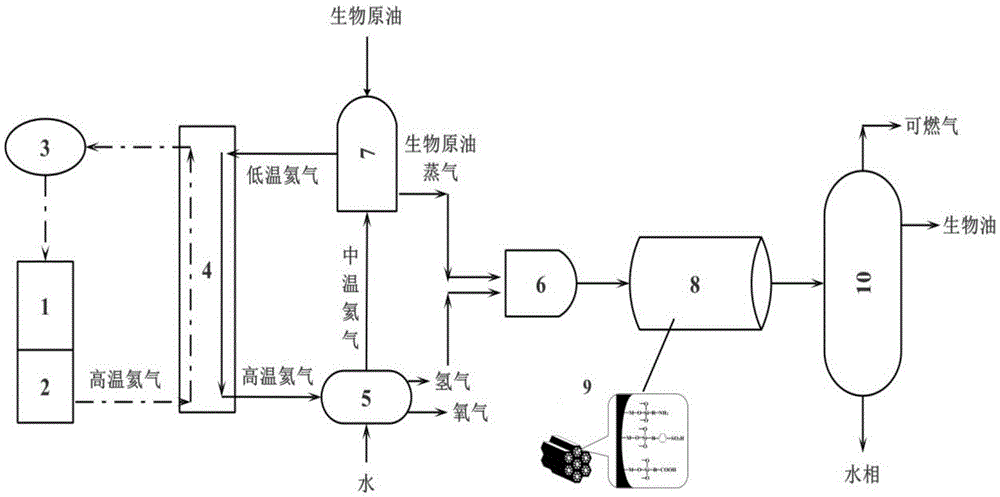

The invention discloses a waterproof and heatproof hydrogenation catalyst. The catalyst is a meso-porous molecular sieve SBA-15 doped with active metal and grafted with an organic functional group, wherein the doped active metal is one or more of Pt, Pd, Zr, Ru, Ni, Co and Mo, and the grafted organic functional group is one or more of an amino group, a carboxyl group and a sulfonyl group. The invention also discloses a method for hydrofinishing biological crude oil by using a high temperature gas cooled reactor. The method comprises the following steps: heating second helium flow with high temperature helium from the core of the high temperature gas cooled reactor, driving a thermochemical circulating hydrogen production process by the second helium flow, preheating and gasifying total components of the oil phase and the water phase of biological crude oil by the second helium flow to form biological crude oil steam, and hydrofinishing the biological crude oil steam and prepared hydrogen under the action of the catalyst to obtain biofuel oil and a non-condensable fuel gas.

Owner:TSINGHUA UNIV

Novel biological fuel oil and formulating method thereof

InactiveCN101319146AAchieve sustainable developmentReproducibleLiquid carbonaceous fuelsLiquid hydrocarbon mixture productionBiodieselEcological environment

The present invention relates to a novel biological fuel oil, in particular to a biological oil using citrus oil as a material and a preparation method thereof. The materials used by the technology are the offal and rejects of fruits, making a break through in the prior production mode of biological diesel oil at home and abroad, which is the biggest contribution made by the technology. The citrus oil is regenerative energy, and can substitute petrifaction fuel. Citrus fruit is evergreen xylophyta which is beneficial to ecological environment improvement. The method for preparing the biological fuel oil by using the citrus oil as the material comprises the following steps that: that raw oil extracted from the materials which are pericarps, stones, roots, branches and leaves, etc. of rutaceae citrus plants such as lemon, pomelo, orange, king orange, mandarin, etc. is subjected to water filtrating, impurity filtering and substance such as pigment, etc. extraction so as to obtain the oil; the oil mainly contains limonene of 95 percent, which is terpene with a molecular formula C10H16 and can be directly used as fuel oil to ignite and burn. The biological oil also can be prepared from the citrus oil of between 50 and 80 percent and methanol (ethanol) of between 20 and 50 percent, by weight percentage.

Owner:李泰春

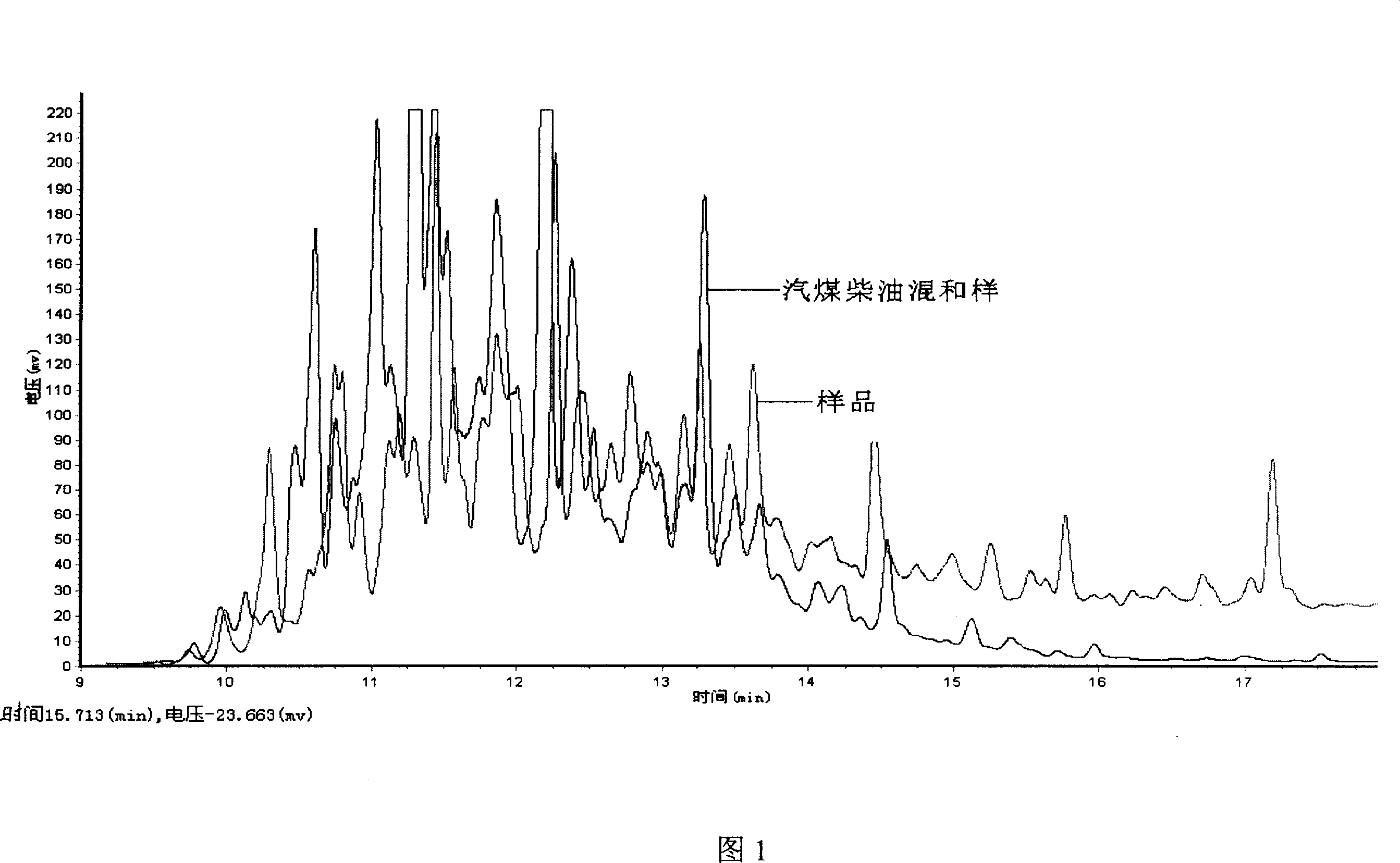

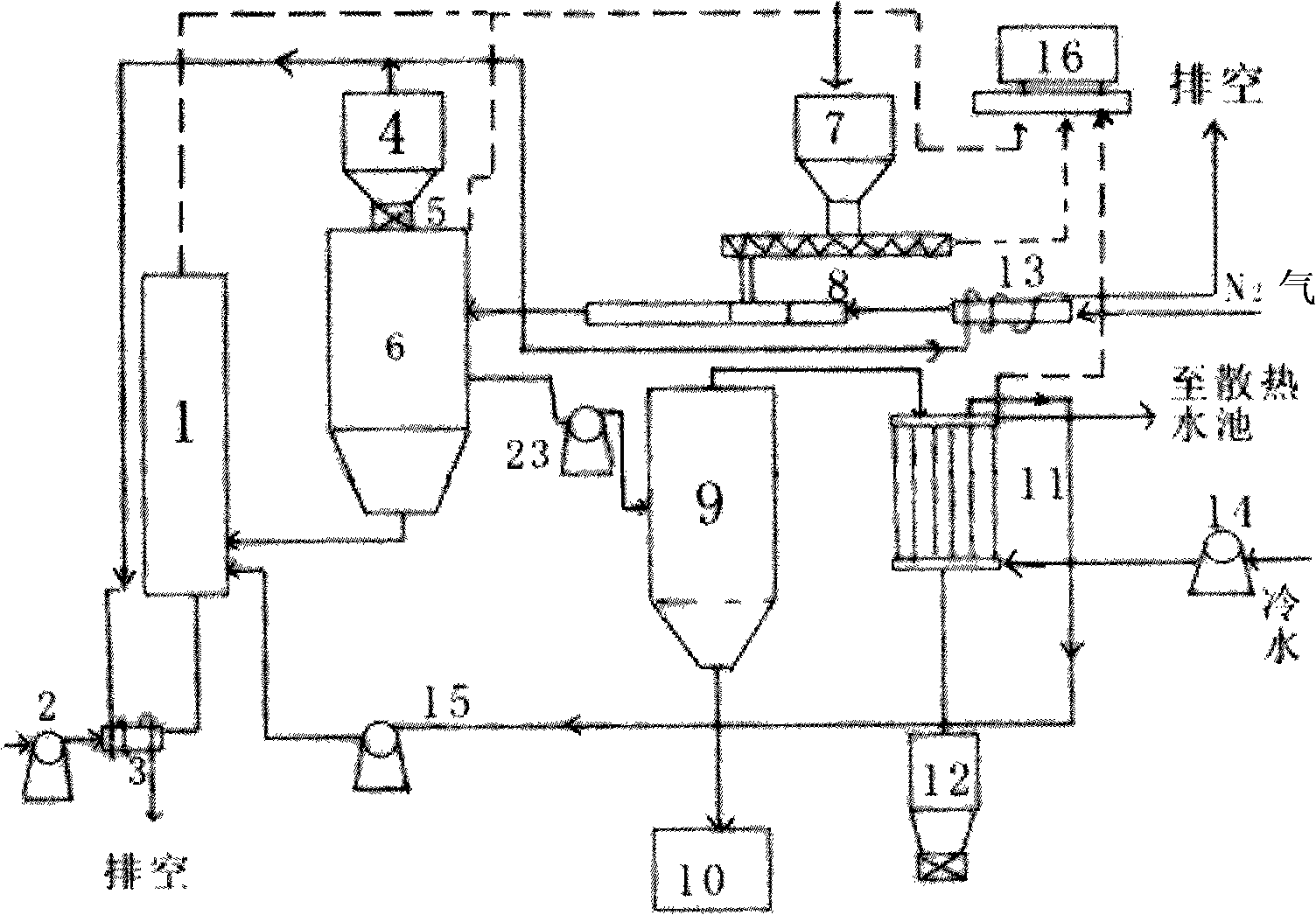

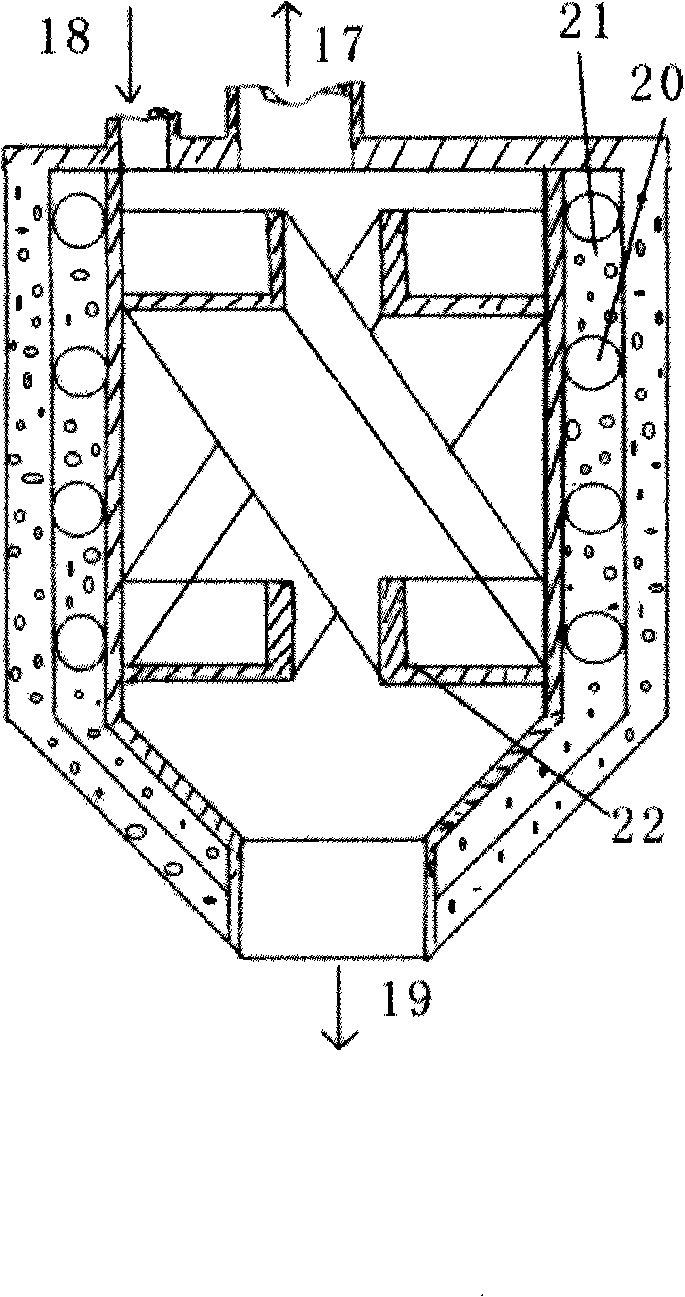

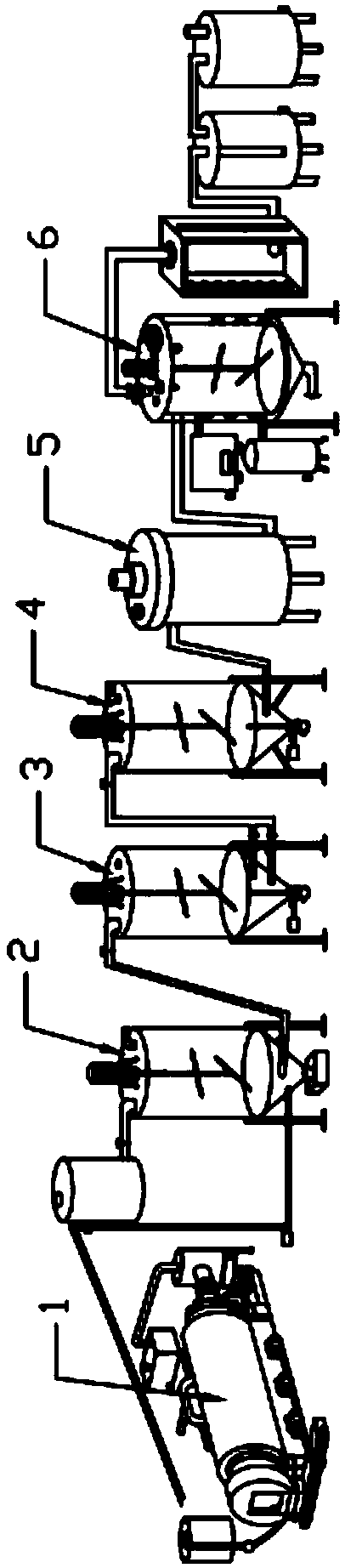

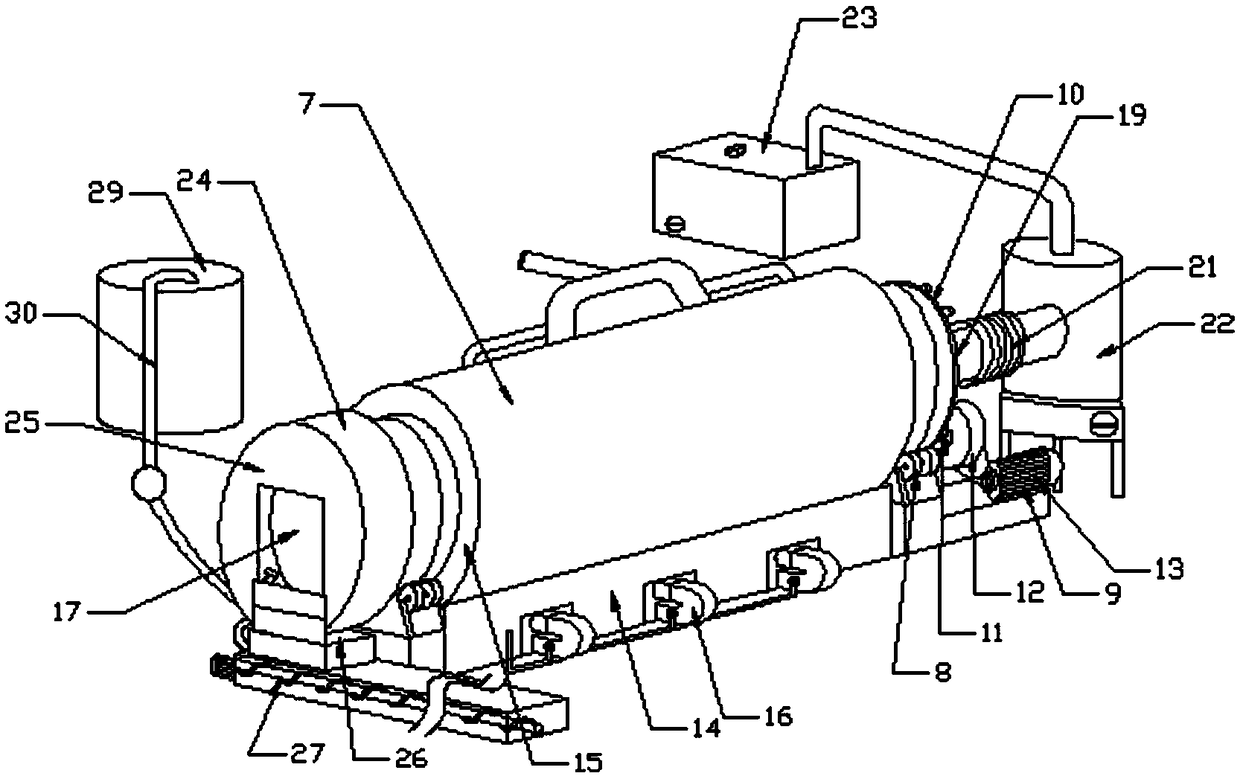

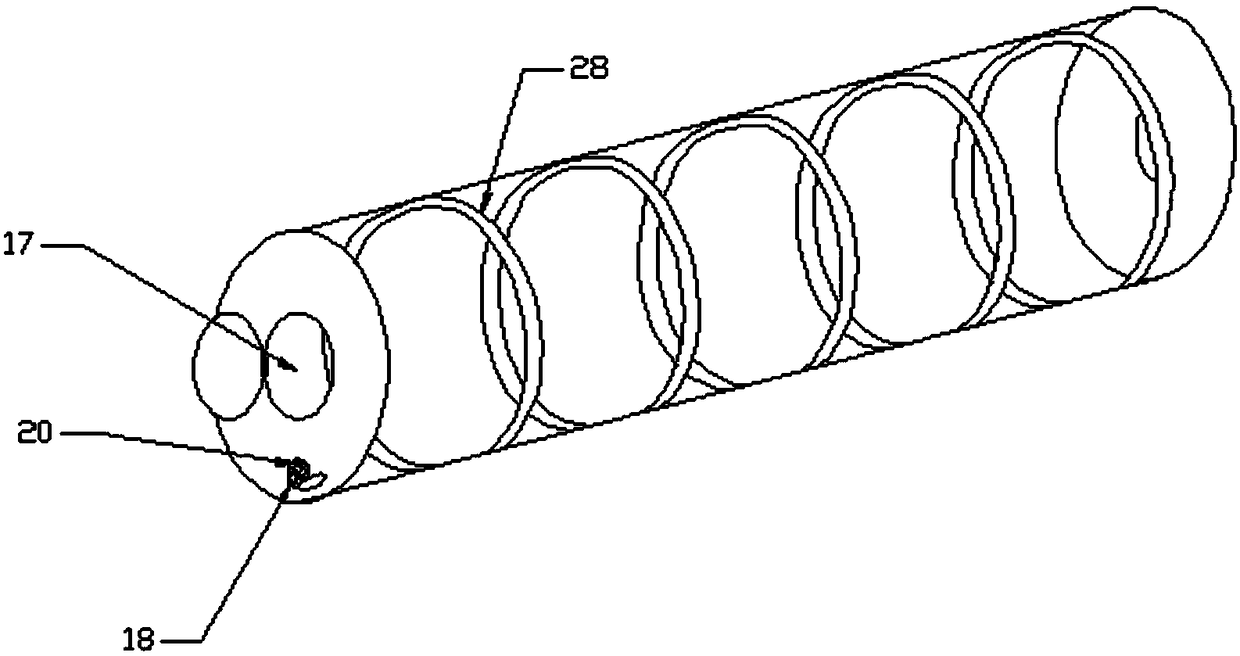

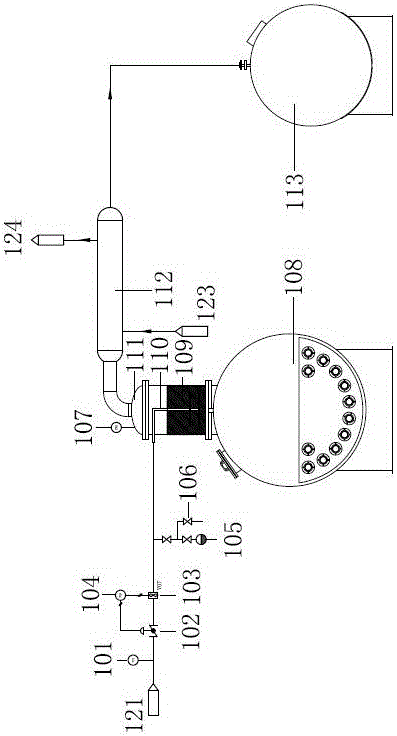

Method for preparing biofuel oil with agronomic crop straw thermal cracking

The invention relates to a method for preparing biofuel oil using crop straws and brushwoods by thermal cracking, in particular to a thermal chemical cracking technology. The method comprises a heat carrier particle heating furnace 1, a cyclone separating device 4, a single-spiral feeder 8, a condenser 11, a fluidized bed cracking furnace 6, a gas-carbon separator 9 and a gathering tank 12. The method has the advantages that: a process system of the invention is suitable for completing thermal cracking and condensing process within 0.5 second, so output capacity of biological oil is high and can reach over 67 percent; and the system adopts a closed loop, residual combustible gas and residual heat can be reused to heat carrier particles, so the method can save energy to reduce cost.

Owner:郭君涛

Preparation method of biofuel oil energy-saving agent

The invention relates to a preparation method of a biofuel oil energy-saving agent. The biofuel oil energy-saving agent is prepared through degrading a chitin derivative chitosan (extracted from marine organism) through an auxiliary enzyme so as to obtain micro molecular chitosan, dissolving the micro molecular chitosan in an organic acid, fermenting so as to obtain a semi-finished product, adding the semi-finished product into mixed liquid of alkane, aromatic hydrocarbons and naphthenic hydrocarbons, fermenting again, and filtering. The biofuel oil energy-saving agent reduces the fuel oil consumption caused by incomplete combustion, increases the calorific value and greatly saves the fuel oil; an effect of protecting machines is achieved, and the biofuel oil energy-saving agent can decompose deposited carbon and colloids produced in fuel oil application, so that the inside of an engine is cleaned, thereby significantly prolonging the service life of the engine; and the exhaust emission is reduced, the environment is protected, the biofuel oil energy-saving agent can increase the cubical content of oxygen and the combusting degree of oil in fuel, and through the complete combustion of the biofuel oil energy-saving agent, the emission of harmful gases is reduced, thereby protecting the environment.

Owner:黄龙哲 +1

Process of preparing biofuel oil and fuel gas with screw extruder

The present invention belongs to the field of comprehensive biomass utilizing technology, and is especially process of preparing biofuel oil and fuel gas with biomass by using screw extruder. Screw extruder is utilized in compressing water-containing biomass material, and by means of regulating the staying time of the biomass material in the heating area of the screw extruder, biofuel oil and fuel gas with low oxygen content and high heat value may be produced. In the product, fuel gas accounts for 50-70 % and biofuel oil 10-20 %, and the obtained biofuel oil has heat value of 30-46 MJ / kg and oxygen content less than 6 %.

Owner:北京瑞增兰宇新能源科技有限公司

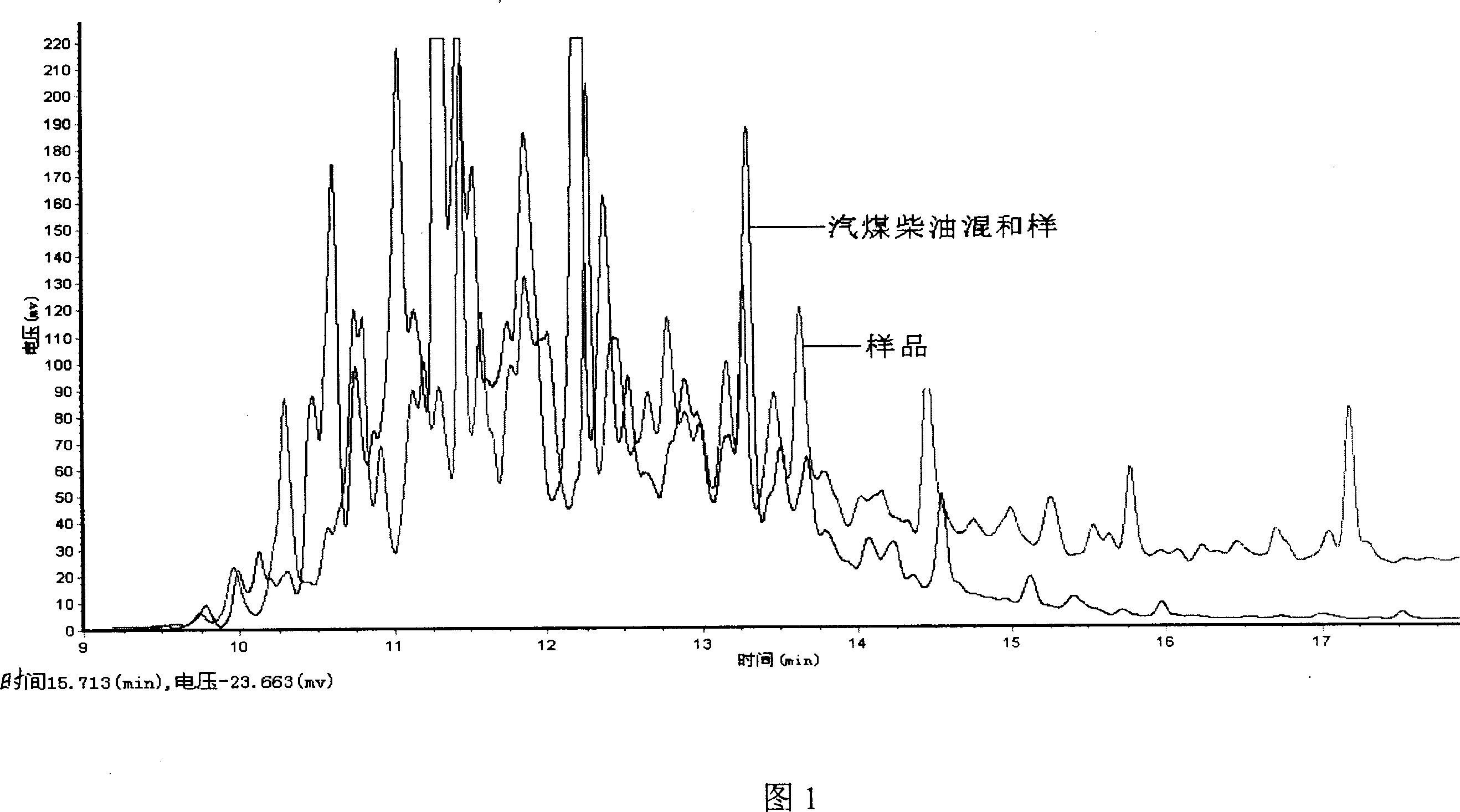

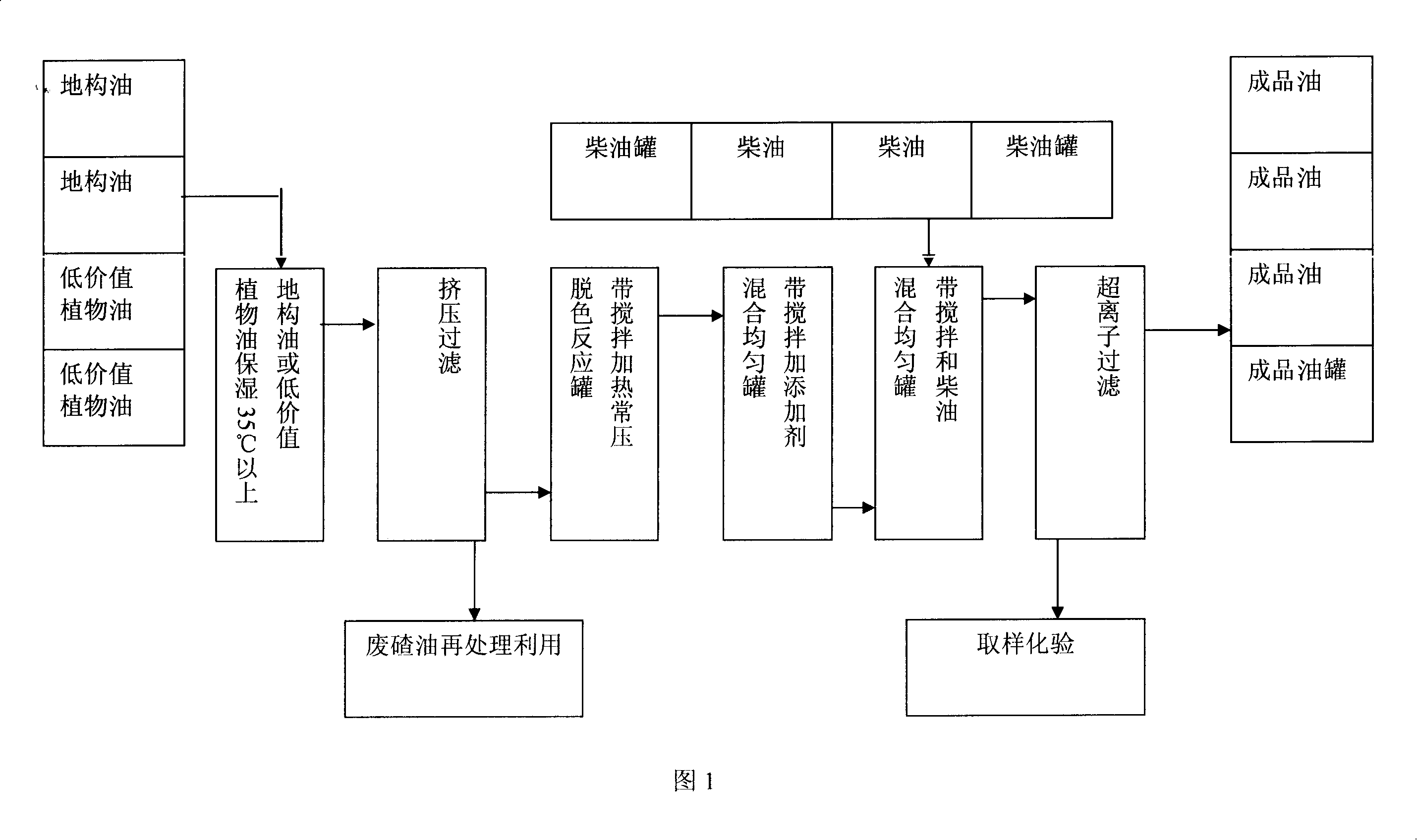

Method for preparing novel biological fuel oil by using cornus wilsoniana oil

InactiveCN101139528AIncrease productionLiquid hydrocarbon mixture productionBio-feedstockBiofuel OilsEngineering

A method for preparing novel biologic fuel oil by using cornus wilsoniana oil is provided, which comprises adding cornus wilsoniana oil and assistant into a raw-material modifying and discoloring tank to modify and discolor, keeping still and separating, adding the modified and discolored crude oil, solvent oil, catalyst, and power enhancing agent into a mixing tank with an agitating device to agitate, keeping still, filtering, getting synthetic fuel agent, mixing the synthetic fuel agent and petrochemical diesel oil to get the novel biologic fuel oil. The time for the modifying and discoloring is 45 minutes, the preparing of the synthetic fuel agent is to fully agitate and react for 30 minutes under normal temperature and normal pressure, the mixing proportion of the synthetic fuel agent and the petrochemical diesel oil is 0-30%. The novel biologic fuel oil prepared by using cornus wilsoniana oil can be equivalently used in any applications using diesel oil, and the use method of the novel biologic fuel is same with that of diesel oil.

Owner:HUNAN ACAD OF FORESTRY

Multicomponent formula combined biological fuel oil and preparation method thereof

InactiveCN103911182APowerfulHigh calorific valueBiofuelsLiquid carbonaceous fuelsBiofuel OilsPetrochemical

The invention provides multicomponent formula combined biological fuel oil and a preparation method thereof. Per 100 parts by weight of the multicomponent formula combined biological fuel oil comprise, in parts by weight, no more than 85 but larger than zero part of a methanol modified composite substance, 5-70 parts of oleic acid, 5-50 parts of n-butanol, 1-8 parts of a surfactant and 1-15 parts of a modified additive; and 0-45 parts by weight of industrial purified water can be added according to specific application. The multicomponent biological fuel oil has the performances similar to those of petrochemical diesel oil and can be mixed with common petrochemical diesel oil according to random ratios or a certain ratio for use, and the multicomponent biological fuel oil has the advantages of high fuel value, high flash point, low condensation point, low cold filter plugging point, low corrosivity, less discharge and low cost.

Owner:深圳智慧能源技术开发有限公司

Method of preparing bio-fuel oil from waste biomass

The invention discloses a method of preparing bio-fuel oil from waste biomass. The method includes the steps of: firstly performing thermo-hydrolysis to the waste biomass and filtering a thermo-hydrolyzed product to obtain bio-crude oil and a water phase; refining the bio-crude oil, and mixing the refined oil with diesel oil, a solvent, mixed ester and an oil-soluble organic metal salt to obtain the bio-fuel oil; and treating the water phase through anaerobic fermentation or supercritical water gasification technology to obtain hydrogen and methane. The method effectively solves environment pollution due to biomass waste gas and alleviates energy crisis, turns waste into resources and saves cost. The bio-fuel oil has no adverse effect on parts in automobile engines and is convenient to use. Through the anaerobic fermentation or supercritical water gasification technology for treating the separated water phase, harmless treatment on the water phase is achieved, which is beneficial to environment protection.

Owner:陈永林

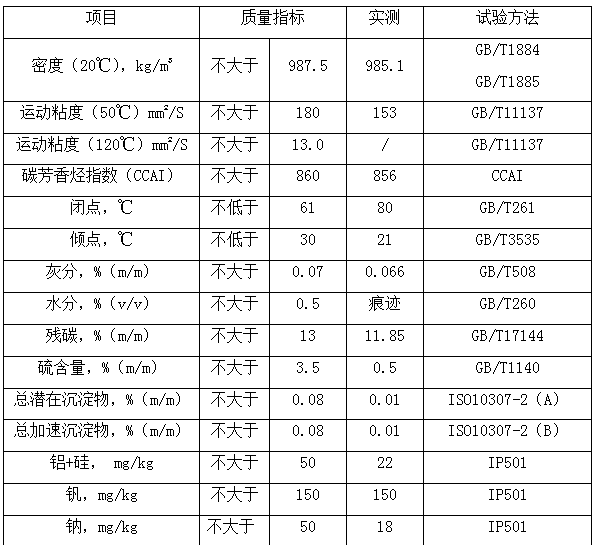

Marine biological fuel oil and preparation method thereof

InactiveCN104789276AHigh calorific valueIncrease oxygen contentLiquid carbonaceous fuelsExhaust gas emissionsWaste oil

The invention discloses marine biological fuel oil which is prepared from the following ingredients in percentage by weight: 30-50 percent of waste plant oil residue, 5-10 percent of waste fusel, 30-50 percent of absorber oil, 15-30 percent of waste oil and 0.5-2 percent of an additive. The marine biological fuel oil makes full use of parts of waste resources and renewable energy sources, can remit the exploitation and consumption of oil resources, and is wide in raw material source, low in cost and good in economic benefit. The marine biological fuel oil is rich in oxygen, good in combustion performance, complete in combustion, high in thermal efficiency, less in exhaust gas emission pollutant and low in sulfur content, reduces mechanical corrosivity and sulfide emission, can be widely applied to the application fields of boilers and ships using petrochemical heavy oil burners, remits the shortage of oil resource, and reduces the pollution of waste oil on social environment.

Owner:舟山冉升能源科技有限公司

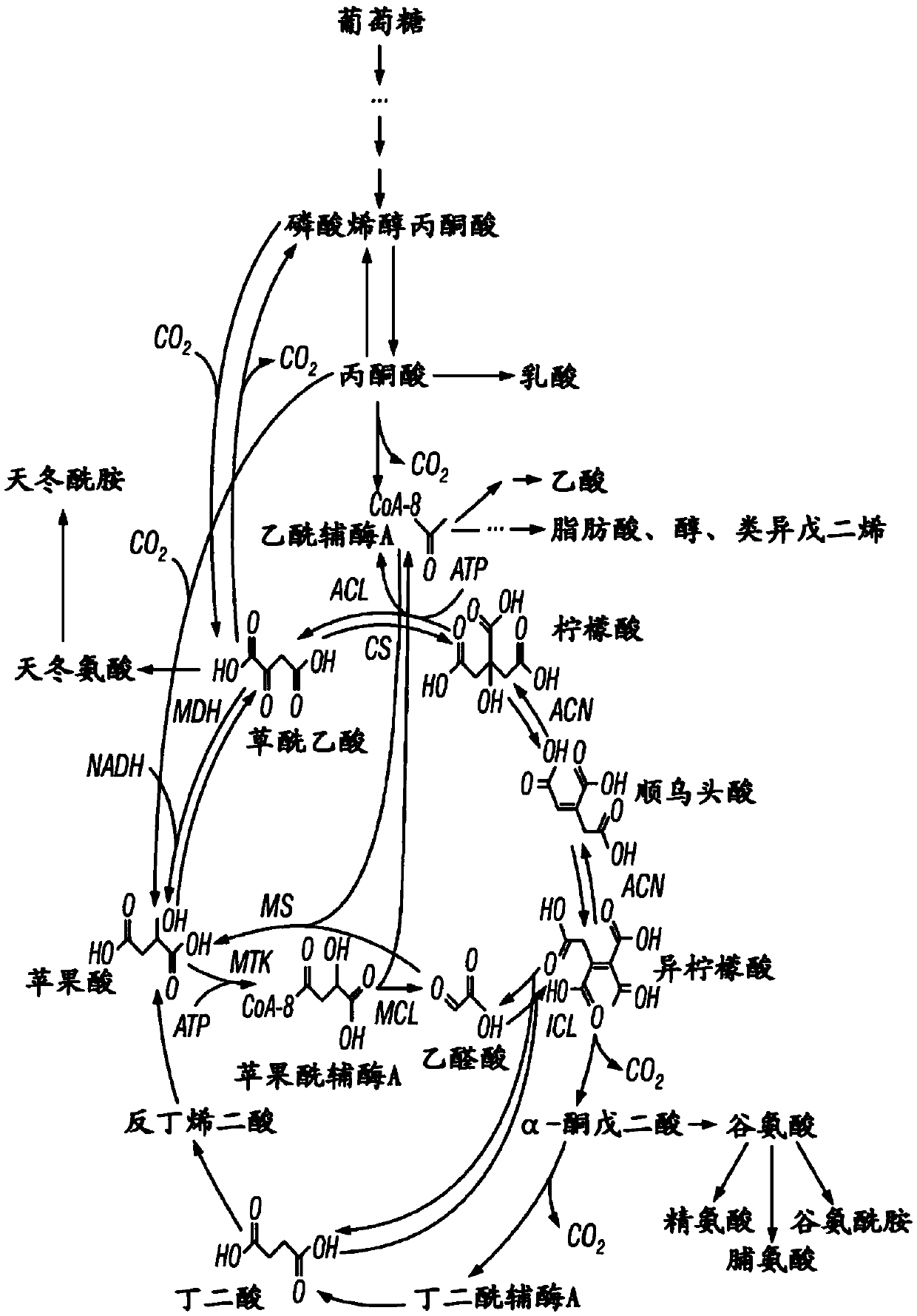

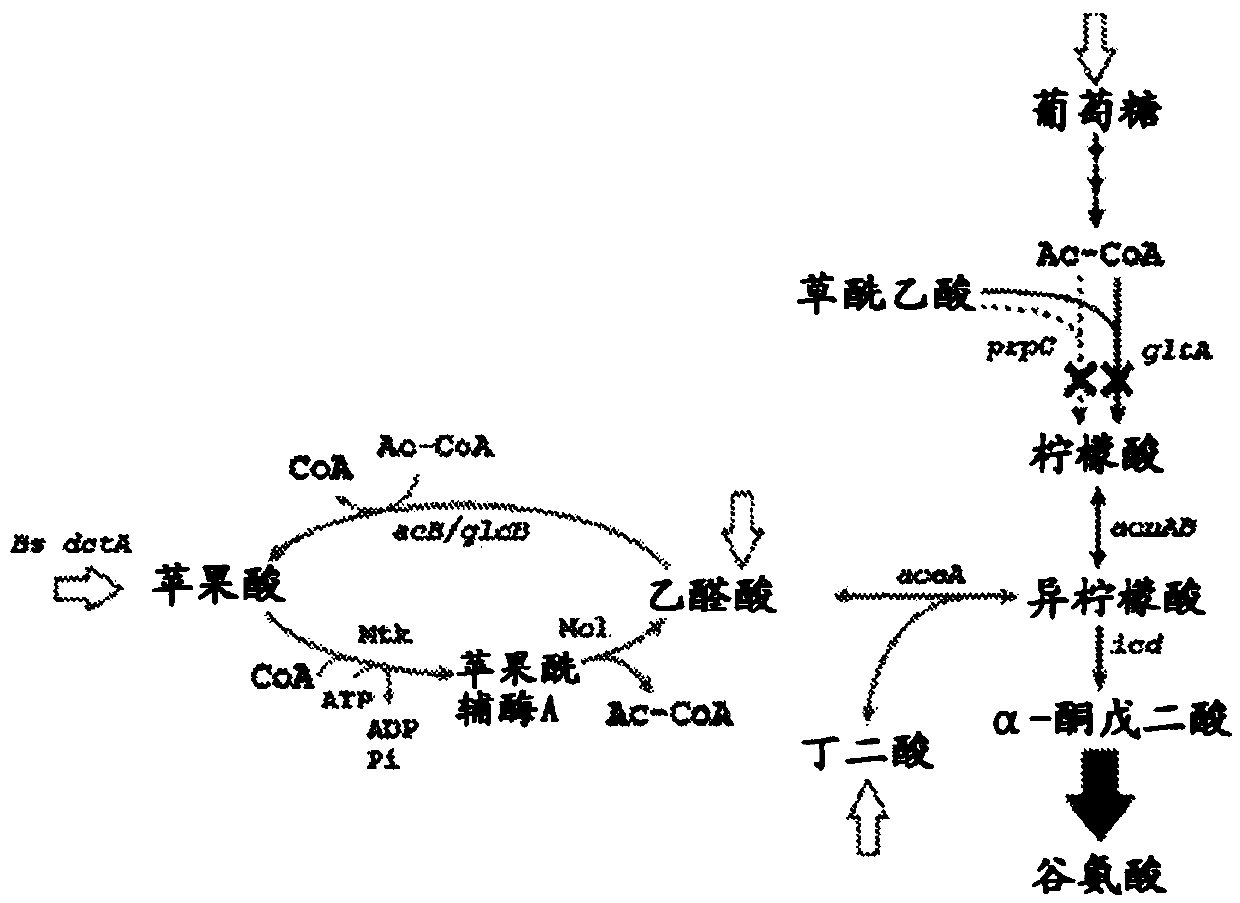

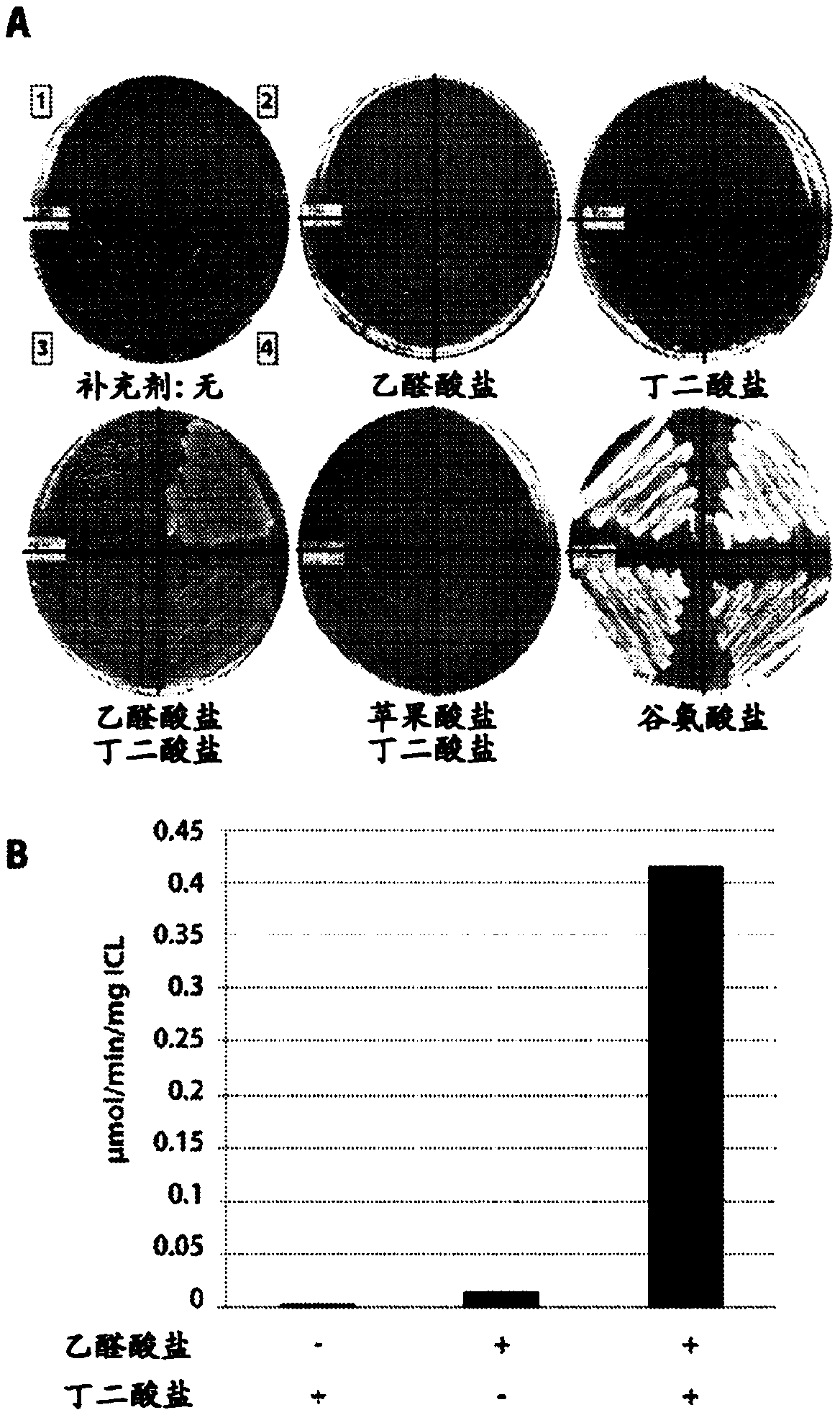

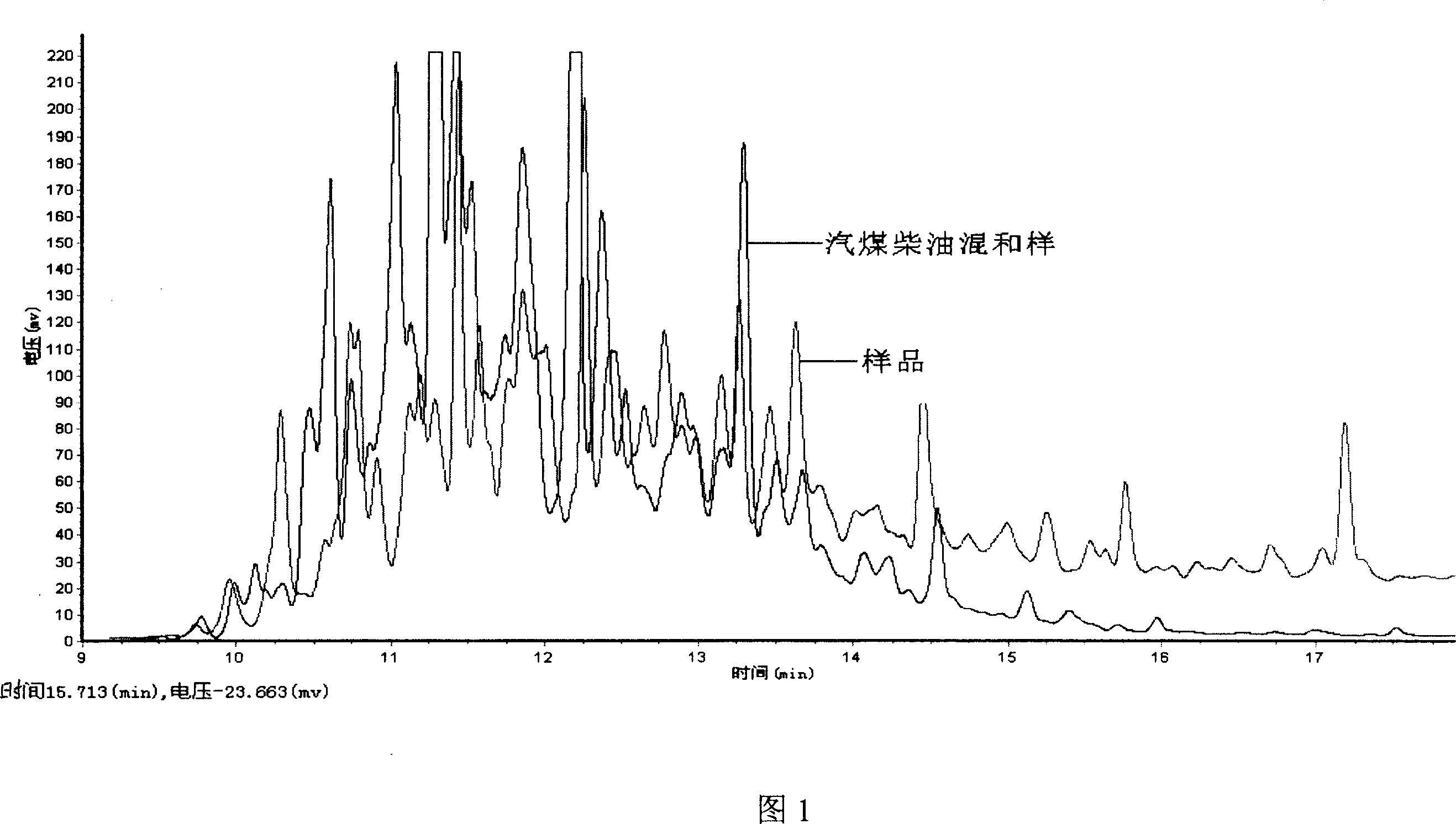

Recombinant plants and microorganisms having a reverse glyoxylate shunt

Provided are microorganisms and plants that express or overexpress enzymes that catalyze the conversion of a four carbon metabolite (malate) to acetyl-CoA. Also provided are methods of generating such organisms and plants and methods of synthesizing biomass, biofuel, oil, chemicals and biochemicals using such organisms and plants.

Owner:RGT UNIV OF CALIFORNIA

Method of producing biological fuel oil from poor oil

InactiveCN101016473AImprove adaptabilityIncrease profitLiquid hydrocarbon mixture productionBio-feedstockChemical industryBiofuel Oils

The invention discloses a preparing method of biological fuel oil with poor oil in chemical industry technical domain, which comprises the following steps: removing water and impurity of raw oil; separating oil and extricate aliphatic acid through vacuum distillation; reacting the oil with carbinol through base catalysis method; getting aliphatic acid methyl ester; reacting extricate aliphatic acid with carbinol through acid catalyst; getting aliphatic acid methyl ester; merging the rough aliphatic acid methyl ester; washing; distilling; refining; getting the product. This invention either increases the adaptability of craft, or improves the availability ratio of raw material.

Owner:安徽省粮油科学研究所

Use of screw extruder in preparing biofuel oil and fuel gas with biomass

InactiveCN101045873ALow oxygenHigh calorific valueLiquid hydrocarbon mixture productionKeroseneBiofuel Oils

The present invention belongs to the field of comprehensive biomass utilizing technology, and is especially use of screw extruder in preparing biofuel oil and fuel gas with biomass. Screw extruder is utilized in compressing water-containing biomass material, and by means of regulating the staying time of the biomass material in the heating area of the screw extruder, biofuel oil and fuel gas with low oxygen content and high heat value may be produced. In the product, fuel gas accounts for 50-70 % and biofuel oil 10-20 %, and the obtained biofuel oil has heat value of 30-46 MJ / kg and oxygen content less than 6 %.

Owner:北京瑞增兰宇新能源科技有限公司

Biofuel oil processing device

PendingCN109181792AEvenly heatedImprove the efficiency of harmless treatmentFatty-oils/fats refiningLiquid carbonaceous fuelsBiofuel OilsPulp and paper industry

The invention belongs to the field of fuel processing equipment and particularly provides a biofuel oil processing device. The device comprises a separation pretreatment device, and a degumming device, a deacidification device, a decoloring device, a dehydrating device and a deodorizing device, which are sequentially connected. The degumming device, the deacidification device, the decoloring device and the deodorizing device are provided with stirring devices. The stirring device comprises a motor, a speed reducer and a stirring shaft connected orderly. The stirring shaft is provided with a first stirring blade and a second stirring blade at intervals. The first stirring blade and the second stirring blade are spiral. The spiral directions of the first stirring blade and the second stirring blade are opposite. The biofuel oil processing device realizes high-temperature sterilization of animal products, automatic oil-water separation and recovery. Through improvement of the stirring device, the oil products to be processed are uniformly mixed so that the processing efficiency of the bio-fuel oil and the quality of the finished oil are improved.

Owner:GUANGXI NANNING GHOST TECH TRADE

Biofuel oil and its prepn process

InactiveCN1931969AWide variety of sourcesLow priceLiquid carbonaceous fuelsBiofuel OilsSmall footprint

The present invention discloses one kind of biofuel oil and its preparation process. The biofuel oil consists of diesel oil, fatty acid, water, modifier A and modifier B in certain weight proportion. Its preparation process includes the first mixing diesel oil, fatty acid and water and heating to 50-90 deg.c; and the subsequent adding modifier A and modifier B and stirring for 5-10 min to obtain the biofuel oil product. The biofuel oil of the present invention has low cost, no pollution, environment friendship, and other advantages.

Owner:刘有望

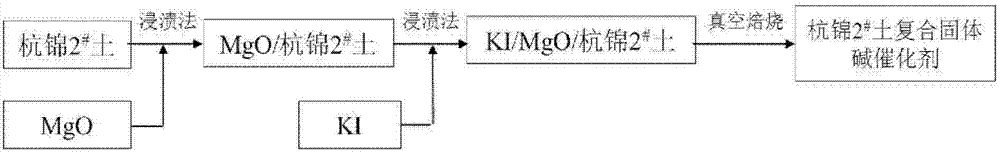

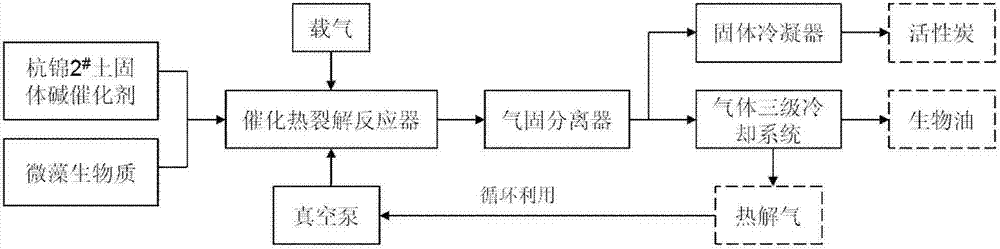

Method for preparing bio-oil by catalyzing and cracking microalgae with supported Hangjin No.2 soil solid base catalyst

InactiveCN102764640ARich reservesEasy to minePhysical/chemical process catalystsCarbon compoundsOil and greaseIce water

The invention relates to a method for preparing bio-oil by catalyzing and cracking microalgae with a supported Hangjin No.2 soil solid base catalyst. The method comprises the steps as follows: microalgae and supported Hangjin No.2 soil solid base catalyst are mixed at the weight ratio of (10:1)-(2:1) and then are placed in a thermal cracking reaction device, wherein nitrogen gas is taken as a carrier gas, the heating rate is 10-30 DEG C / min, and the temperature is raised to 350-600 DEG C; and gas generated during thermal cracking process is taken out of the reactor by the carrier gas, undergoes a three-stage cooling system of liquid nitrogen, dry ice and ice-water mixture, and then is collected to obtain liquid bio-oil. The invention further discloses the supported Hangjin No.2 soil solid base catalyst. According to the invention, on the basis that the supported compound solid base catalyst with high activity, high selectivity and low cost is synthesized, microalgae with high grease content is adopted and is transformed into bio-fuel oil through high-temperature catalytic cracking reaction, so that reaction temperature is lowered, green biological energy sources with excellent performances are obtained, and dual purposes of microalgae environmental management and high-value utilization of resources are achieved.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

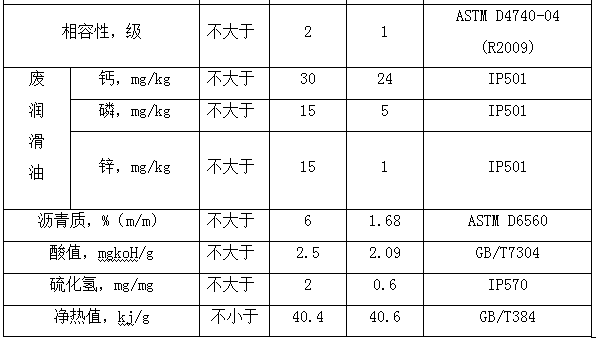

Method for producing environment-friendly blending component of marine fuel oil by adopting catalyst-free glycerol esterified hogwash oil

InactiveCN108300572ANo pollutionSimple processFatty acid esterificationLiquid carbonaceous fuelsBiofuel OilsAcid value

The invention provides a method for producing an environment-friendly blending component of marine fuel oil by adopting catalyst-free glycerol esterified hogwash oil. The hogwash oil is subjected to glycerol esterification to obtain biological fuel oil of which the acid value is less than or equal to 6.5mgKOH / g, the ash content is less than or equal to 0.1% and the pour point is less than or equalto 30 DEG C. The hogwash oil is subjected to catalyst-free heating and vacuum glycerol esterification to obtain the biological fuel oil which serves as the blending component of the marine fuel oil,and the method provided by the invention is simple in process, environment-friendly, pollution-free, low in production cost and easy to realize industrialization.

Owner:MAOMING KAIYUE SPECIAL AGENT

Method and an apparatus for refining biomass fuel oil by hydration catalysis means

PendingCN105907480ASimple processImprove product qualityFatty acid chemical modificationLiquid carbonaceous fuelsAlkaneOil and grease

The invention provides a method and an apparatus for refining biomass fuel oil by a hydration catalysis means. The method comprises the following steps: a molecular sieve catalyst is used, water vapor is introduced for carrying out a catalytic cracking reaction, and a hydration catalytic cracking reaction is formed; water vapour is directly involved in the reaction in order to accomplish formation of alkanes from unsaturated hydrocarbons, and an esterification reaction of fatty acid and oleic acid is accomplished synchronously. The method has a simple process, the quality of the product is stable, and the method and the apparatus are better suitable for refining biomass fuel oil from waste oil and fat of animals and plants as well as waste plastics.

Owner:中科国发(深圳)技术有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com