Method for producing environment-friendly blending component of marine fuel oil by adopting catalyst-free glycerol esterified hogwash oil

A technology for blending components and fuel oil, which is applied in the direction of fuel, fatty acid esterification, liquid carbon-containing fuel, etc., can solve the problems of unsolved waste oil biofuel, etc., and achieve low production cost, easy industrialization, and environmentally friendly methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

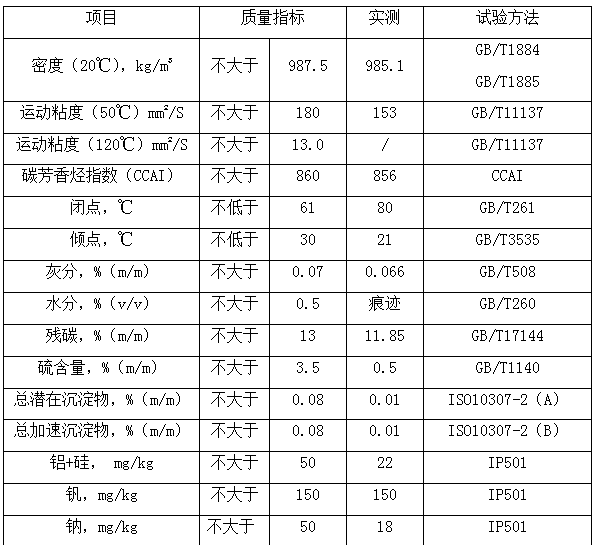

Embodiment 1

[0014] Put 300g of waste oil and 50g of glycerin into a decompression bottle, and vacuumize to 4.5×10 4 Pa, gradually increase the temperature, discharge water to 235°C, and react stably for 4 hours to obtain 323g of biofuel oil; compatibility: first grade, acid value: 6.29mgKOH / g; ash content ≤ 0.078% (m / m); pour point ≤ 21 ℃.

Embodiment 2

[0016] Put 300g of waste oil and 50g of glycerin into a decompression bottle, and vacuumize to 5.0×10 4 Pa, gradually increase the temperature, discharge water to 240°C, and react stably for 4 hours to obtain 320g of biofuel oil; compatibility: first grade, acid value: 6.06mgKOH / g; ash content ≤ 0.07% (m / m); pour point ≤ 21 ℃.

Embodiment 3

[0018] Put 300g of waste oil and 50g of glycerin into a decompression bottle, and vacuumize to 5.5×10 4 Pa, gradually increase the temperature, discharge water to 245°C, and react stably for 4 hours to obtain 315g of biofuel oil; compatibility: first grade, acid value: 5.922mgKOH / g; ash content ≤ 0.08% (m / m); pour point ≤ 21 ℃.

[0019] Density at 25°C: 923.2kg / m 3

[0020] Kinematic viscosity at 50°C: 38.3mm2·S -1

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com