Method for preparing novel biological fuel oil by using cornus wilsoniana oil

A technology of eucalyptus oil and fuel oil, which is applied to the preparation of biological raw materials, liquid hydrocarbon mixtures, and the petroleum industry, and can solve the problems of low output, high cost, and high raw material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

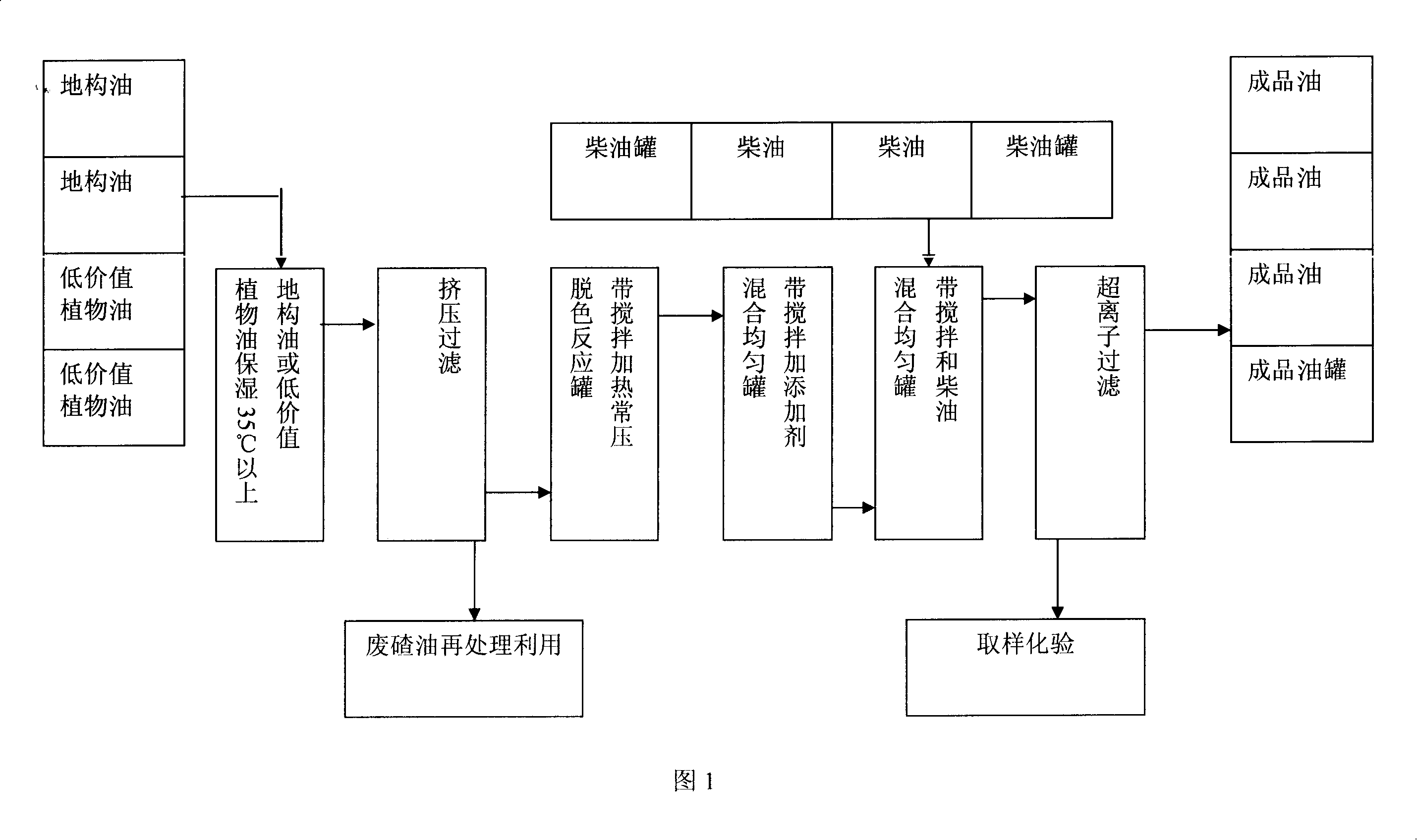

Image

Examples

Embodiment 1

[0017] Mix the synthetic fuel and diesel at a ratio of 20% and 80%, and its preparation method is shown in (A, B, C) of Article 3 of this chapter. The novel biofuel oil synthesized by this example is equivalent to the national standard GB5 # diesel standard.

Embodiment 2

[0019] Mix the synthetic fuel agent and diesel oil at a ratio of 10% and 90%, and the preparation process is shown in (A, B, C) of Article 3 of this chapter. The novel biofuel oil synthesized by this example is equivalent to the national standard GB0 # diesel standard.

Embodiment 3

[0021] Mix synthetic fuel and diesel at a ratio of 30% and 70%, and its preparation process is shown in (A, B, C) of Article 3 of this chapter. The novel biofuel oil synthesized by this example is equivalent to the national standard GB10 # diesel standard.

[0022] The above-mentioned novel biofuel oil (1) can be equally used in all diesel application fields. (2) The method of use is equivalent to that of diesel (see the content of the instructions for use of diesel). (3) For the required equipment and process, see the flow chart of the following process equipment.

[0023] Note 1: The additive is hydrogen peroxide

[0024] Note 2: Solvent oil is diesel oil with cetane number less than 50 or gasoline with octane number less than 90

[0025] Note 3: The catalyst is a polymer hormone enzyme

[0026] Note 4: The power enhancer is a cetane number enhancer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com