Process of preparing biofuel oil and fuel gas with half-dried biomass

A biofuel and biomass technology, applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, etc., can solve the problems of low calorific value, complicated operation, high oxygen content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Mix 5g rice straw powder (0.5~0.8mm) with 1ml water evenly, compact it into a 10ml miniature airtight reactor, raise the temperature to 320□ at a heating rate of 25□ / min, keep it for 1 hour, collect the generated combustible gas, and end reaction. After the reaction is cooled, the dregs are distilled at atmospheric pressure, and the temperature is raised to 350□ to obtain biofuel liquid. The output of combustible gas accounts for 60% of the raw material, the output of bio-fuel is 15%, the calorific value is 41.26MJ / kg, and the oxygen content is less than 6%.

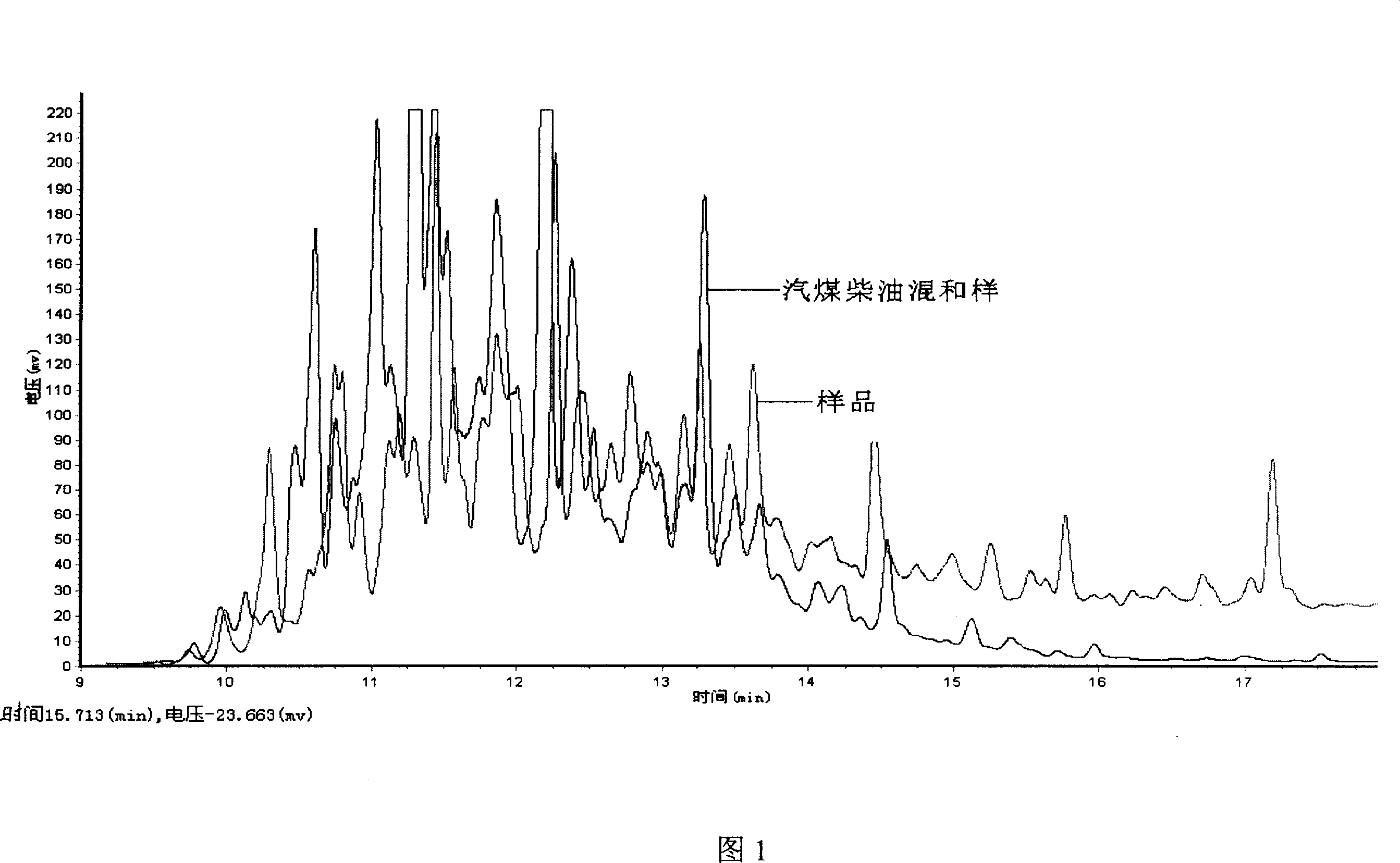

[0013] It can be seen from the accompanying drawings that the chromatographic peaks of the obtained biofuel substantially overlap with the chromatographic peaks of commercially available gasoline, diesel oil, and kerosene mixed samples. According to the results of mass spectrum peak analysis, the main components of the obtained biofuel are:

[0014] (1) Hydrocarbons mainly include: decane, undecane, dodecane, tr...

Embodiment 2

[0018] 5g of corn stalks were crushed into powder (1.0-1.5mm) and mixed with 4ml of water, compacted into a 10ml airtight reaction kettle, heated to 400°C at a heating rate of 10°C / min, kept for 1.5 hours, and collected gas to end the reaction. After the reaction is cooled, the dregs are distilled at atmospheric pressure, and the temperature is raised to 420°C to obtain biofuel liquid. The output of combustible gas accounts for 55% of the raw material, the output of bio-fuel is about 13%, the calorific value is 38.9MJ / kg, and the oxygen content is less than 6%.

Embodiment 3

[0020] Crush 5g of soybean straw into powder (10-15mm) and mix it with 3ml of water, compact it into a 10ml airtight reaction kettle, raise the temperature to 380°C at a heating rate of 40°C / min, keep it for 2 hours, and collect the generated combustible gas , to end the reaction. After the reaction is cooled, the dregs are distilled at atmospheric pressure, and the biofuel liquid is obtained when the temperature rises to 400°C. The output of combustible gas accounts for 65% of the raw material, the output of bio-fuel is about 18%, the calorific value is 39.8MJ / kg, and the oxygen content is less than 6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com