Method for preparing fuel oil biological butanol by using cassava as raw material

A technology of bio-butanol and fuel oil, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., to achieve high octane number, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

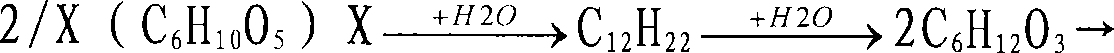

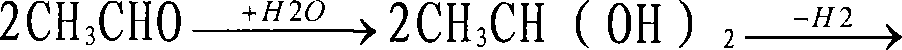

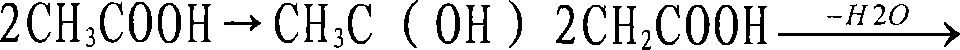

Method used

Image

Examples

Embodiment 1

[0046]Weigh 1 kg of cassava refined starch, put it into the mixing tank, add 9 kg of clear water and soak it at room temperature, so as to dissolve various impurities in the water, add hydrochloric acid to the soaking solution, adjust the pH value to 4, soak for 5 hours Discard the sundries in the upper layer, and soak for three times to end. Adjust the concentration of the washed cassava flour to 17Be, then add 10 grams of S1010 catalyst, the catalytic temperature is 100°C, stir, and the reaction is completed in 0.5 hours. Cool the liquid to 37°C, add CL·a-b Np-1 strain to ferment, the inoculum size is 150 grams, and after inoculation, keep it at 42°C for 50 hours to ferment to produce a mixture of bio-butanol, acetone and ethanol. First, the mixed solution is distilled to a solvent solution with a concentration of about 30% through a rectification tower, and the temperature is controlled at 90°C, and then the mixed solution is separated at 70°C to separate acetone and ethano...

Embodiment 2

[0048] Weigh 100 kg of cassava chips, crush them, put them into the pulping tank, add 1000 kg of clear water to soak, so that various impurities can be dissolved in water, and add N a OH, adjust the pH value to 9, soak for 10 hours and discard the upper debris, and end the second soak. Adjust the concentration of the cleaned cassava flour to 20Be, then add 1 kg of S1010 catalyst, and stir at a catalytic temperature of 70°C. After 1.5 hours of reaction, heat up to 100°C and keep it for 20 minutes, then cool the liquid to 32°C, add CL·a-b Np -1 strain fermentation, the inoculum amount is 10 kg, and after inoculation, it is incubated and fermented at 40°C for 70 hours to generate a mixture of bio-butanol, acetone and ethanol. First, the mixed solution is distilled to a solvent solution with a concentration of about 25% through a rectification tower, and the temperature is controlled at 90°C, and then the mixed solution is separated at 78°C to separate acetone and ethanol, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com