Method for preparing bio-oil by catalyzing and cracking microalgae with supported Hangjin No.2 soil solid base catalyst

A solid base catalyst, supported technology, applied in chemical instruments and methods, carbon compounds, chemical/physical processes, etc., can solve the problems of short service life, difficult industrial application, poor stability, etc., and achieve lower production costs and lower costs. , the effect of easy mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Screening and cultivation of algal species

[0041] The algal species used in this example is a high-lipid-content Chlorella pyrenoidosa that was independently screened in a freshwater lake and has both autotrophic and heterotrophic functions. The composition of the culture medium is as follows: a strain of chlorella pyrenoidosa with both autotrophic and heterotrophic growth capabilities, the oil content of the chlorella is 30-50%, and the protein content is 40-60%. The composition of Chlorella pyrenoidosa culture medium is as follows (1000mL deionized water): MgSO 4 7 hours 2 O 0.5-2.0g, Na 2 HPO 4 12H 2 O 0.5-2.0g, KNO 3 0.5-2.0g, CaCl 2 0.01-0.05g, EDTA-2Na 0.01-0.05g, ferric ammonium citrate 0.01-0.05g. The initial pH of this prepared medium is 6.5-8.0.

[0042] Preferred medium composition (1000mL deionized water): MgSO 4 ·7H 2 O 1.0g, Na 2 HPO 4 12H 2 O 1.5g, KNO 3 2.0g, CaCl 2 30mg, EDTA-2Na 50mg, ferric ammonium citrate 10mg. The initial pH...

Embodiment 2

[0050] 1) Screening and cultivation of algal species

[0051] The algal species used are Dunaliella salina and Scenedesmus, and the screening and cultivation are the same as those in Example 1, so no repeated description is given here.

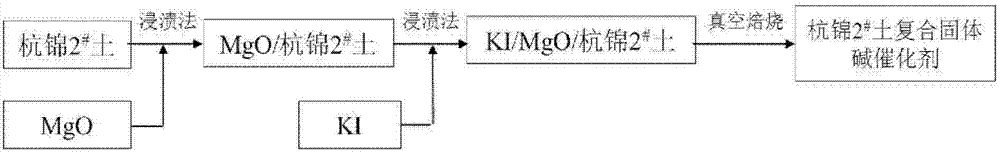

[0052] 2) Loaded KI / MgO / Hangjin 2 # Preparation of soil solid alkali catalyst:

[0053] Take MgO / Hangjin 2 respectively # Soil and KI were added into water according to 2:5 (mass ratio), stirred, heated and activated in a constant temperature water bath at 100°C for 4 hours. After the activation reaction is completed, cool, filter with suction, and wash until the pH value is 5-6, then dry the filter cake at 105°C. After drying, grind it into powder, bake it in a vacuum heating furnace at 300°C for 2 hours, put it in a desiccator and cool it to room temperature, pass it through a 200-mesh sieve, and keep it sealed.

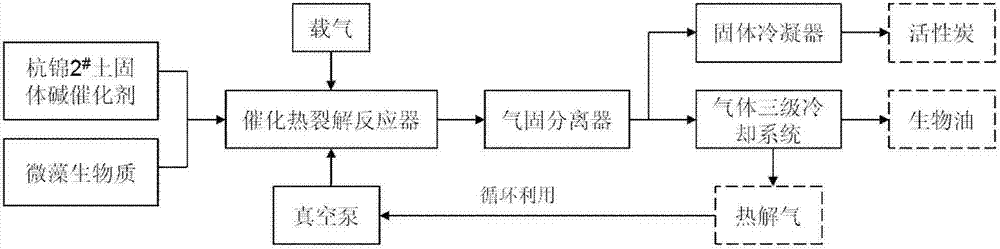

[0054] 3) Preparation of biofuel oil by catalytic cracking of microalgae

[0055] The prepared KI / MgO / Hangjin 2 # The soil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com