Method for preparing biofuel oil with agronomic crop straw thermal cracking

A technology for crop straw and thermal cracking, which is applied in the preparation of liquid hydrocarbon mixtures and the petroleum industry, etc., can solve the problems of low bio-oil yield, waste of surplus energy resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

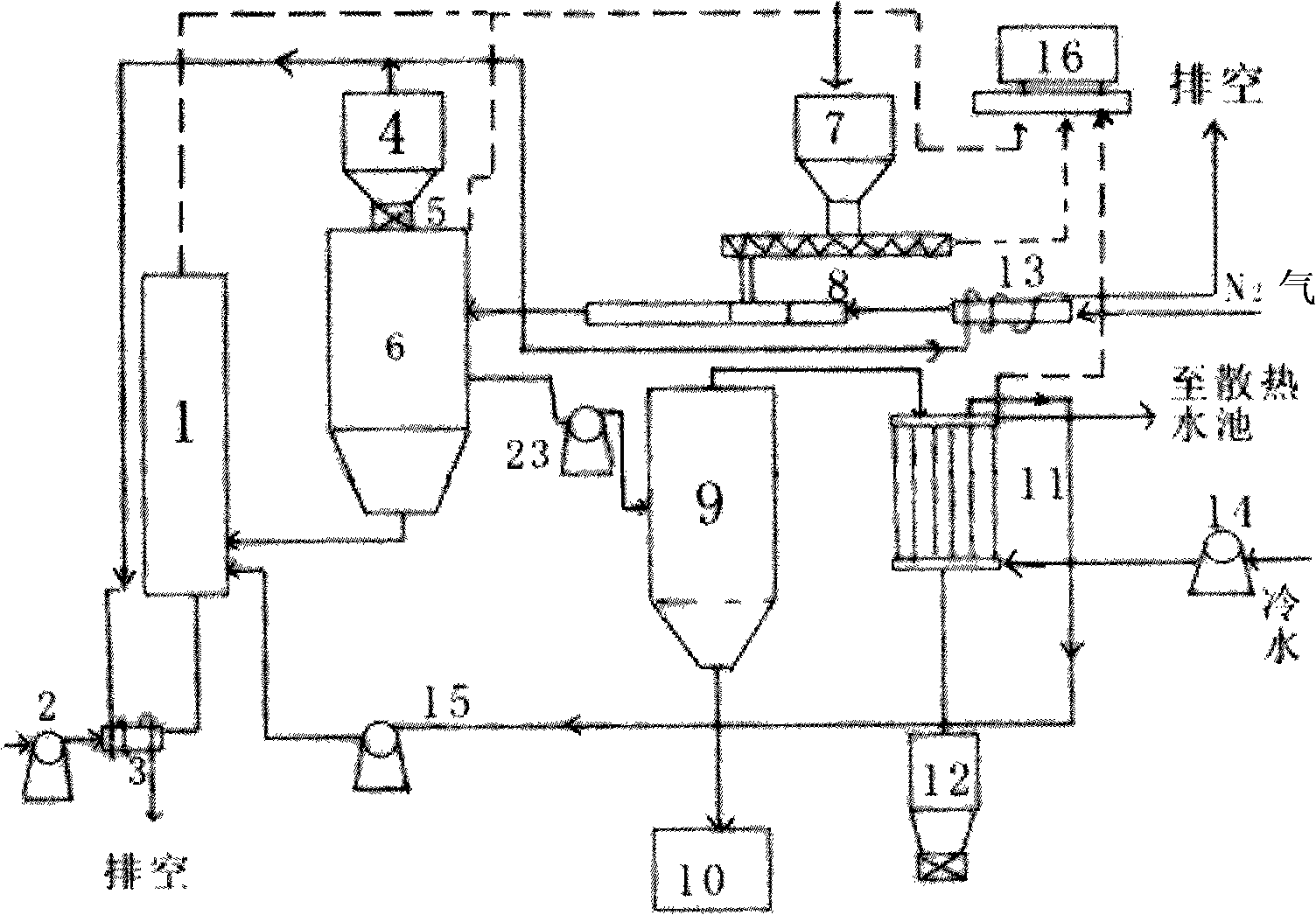

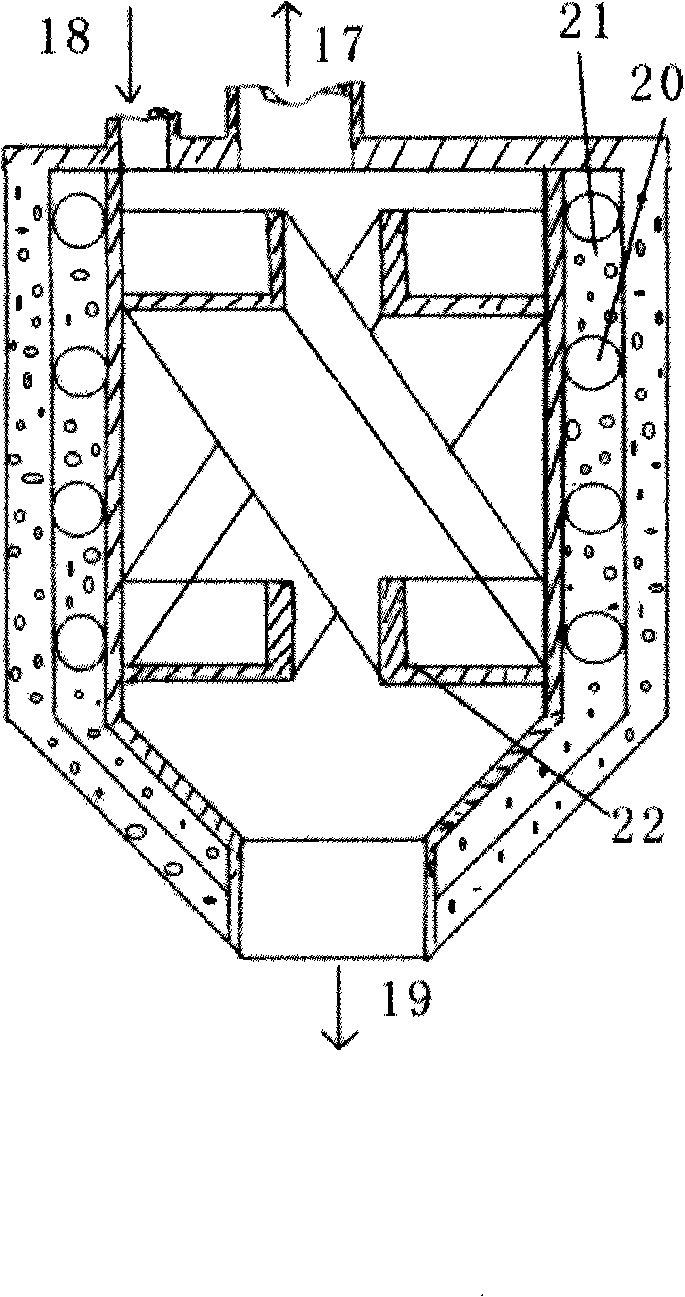

[0016] Among the figure "1"; the air blown by the blower fan "2" is delivered to the heat carrier particle heating furnace "1" by the air heater "3", and burns with the combustible gas introduced by the gas delivery pump "15". The heated heat carrier particles are sent to the cyclone separator "4", and the gas and particles are separated. Its hot air is sent to air heater "3" and nitrogen heater "13" for heating the gas. The hot carrier particles enter the upper part of the fluidized bed cracking furnace "6" through the valve "5". The biomass particles are blown from the biomass hopper "7", through the screw feeder "8", and the nitrogen gas flow heated by the nitrogen heater "13". It is ejected from the biomass particle nozzle "18" and mixed with heat carrier particles. Enter fluidized bed cracking furnace " 6 " under the effect of air-flow, spray into the raw material guide rail " 22 " upper end entrance that the inner wall of garden cylinder is installed. Biomass and heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com