Comprehensive utilization method of vinasse

A technology of distiller's grains and distiller's grains powder, which is applied in chemical instruments and methods, carbon compounds, hydroxyl compound preparation, etc., can solve the problems of different market demands, inability to fully utilize distiller's grains, uneven geographical distribution, etc., and achieve high added value, operation Simple, pollution-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

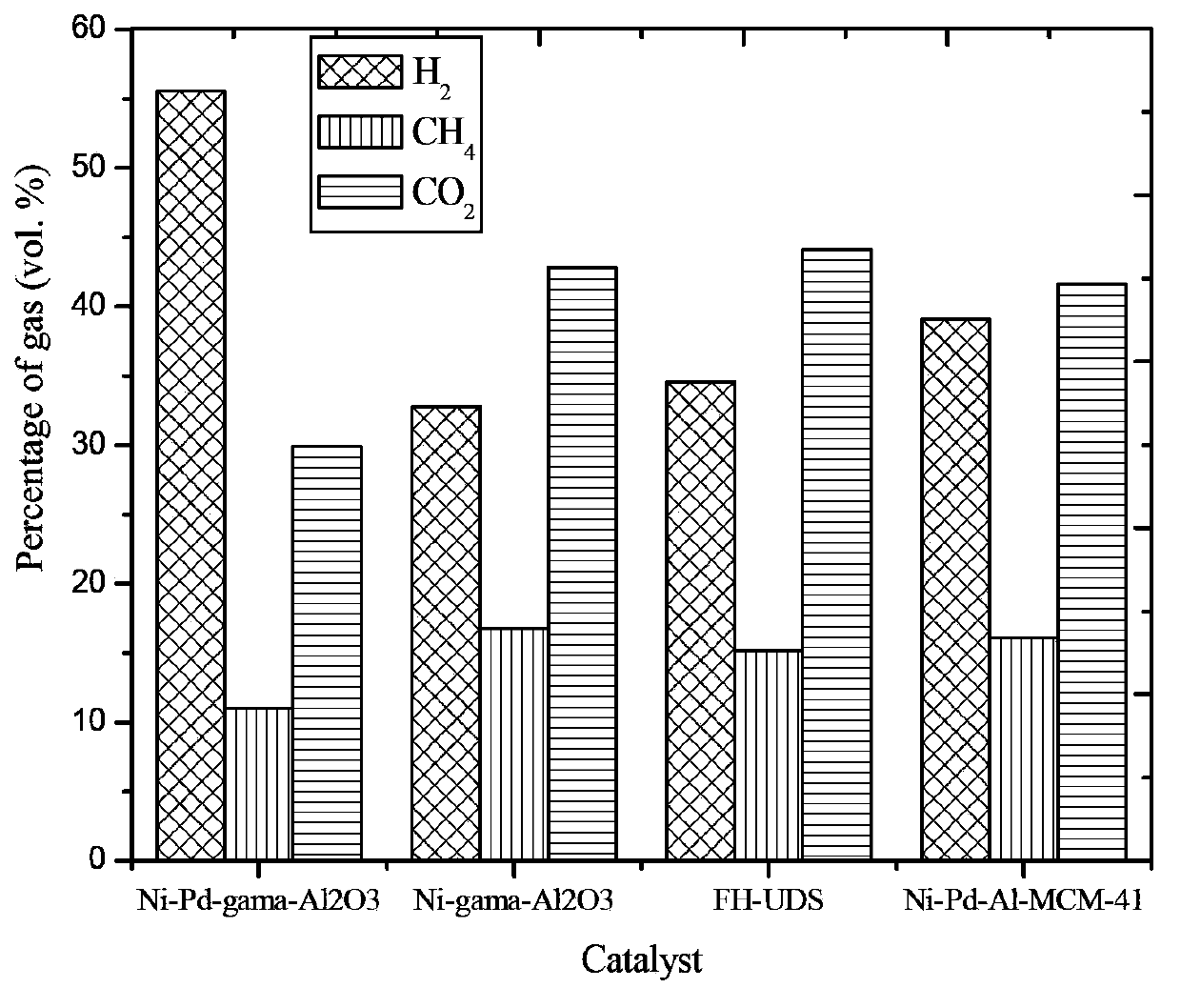

[0066] Catalyst Ni-γ-Al 2 o 3 and catalyst Ni-Pd-γ-Al 2 o 3 It is homemade by impregnation: γ-Al 2 o 3 It is commercially available and developed by Tianjin Chemical Industry Research and Design Institute; the preparation method comprises the following steps:

[0067] Catalyst prepared as Ni-γ-Al 2 o 3 Take nickel nitrate from time to time to prepare catalyst Ni-Pd-γ-Al 2 o 3 Take palladium chloride and nickel nitrate from time to time, add distilled water to the obtained raw materials to make a solution and impregnate γ-Al at room temperature 2 o 3 After 24 hours, the moisture was removed under reduced pressure at room temperature, dried in an oven at 90-100°C, and finally aerobically decomposed in a muffle furnace at 560°C for 6 hours to obtain the catalyst.

[0068] Further, the catalyst is Ni-Pd-Al-MCM-41, the main component is 1Si:0.06Al:0.005Pd:0.1Ni:0.2C in molar ratio 16 :64H 2 O, wherein Si, Al, Pd or Ni in the molar ratio represent their elements respecti...

Embodiment 1

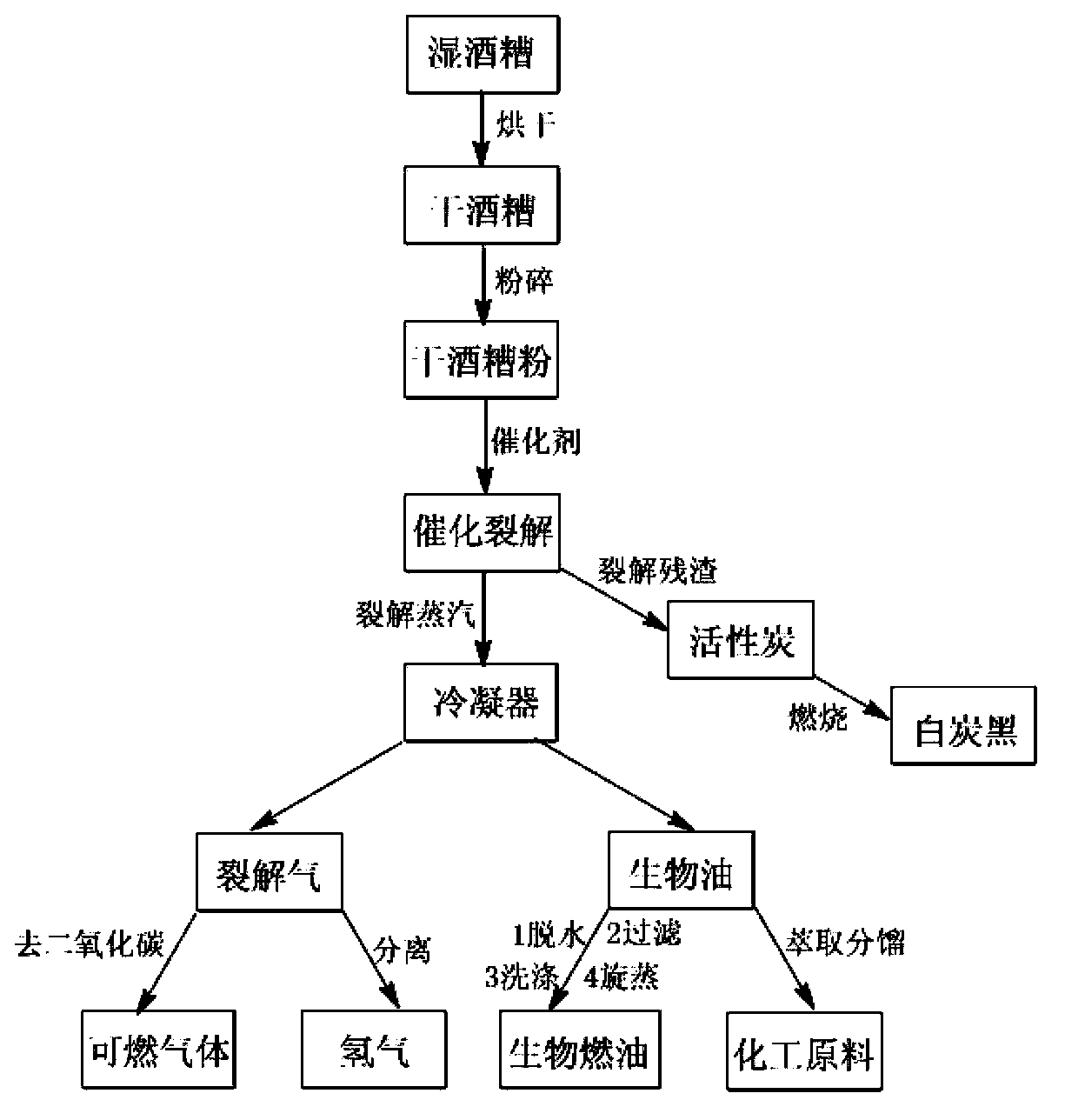

[0093] Example 1 Production of bio-fuel or chemical raw materials, high calorific value gas or hydrogen and activated carbon by catalytic cracking of distiller's grains

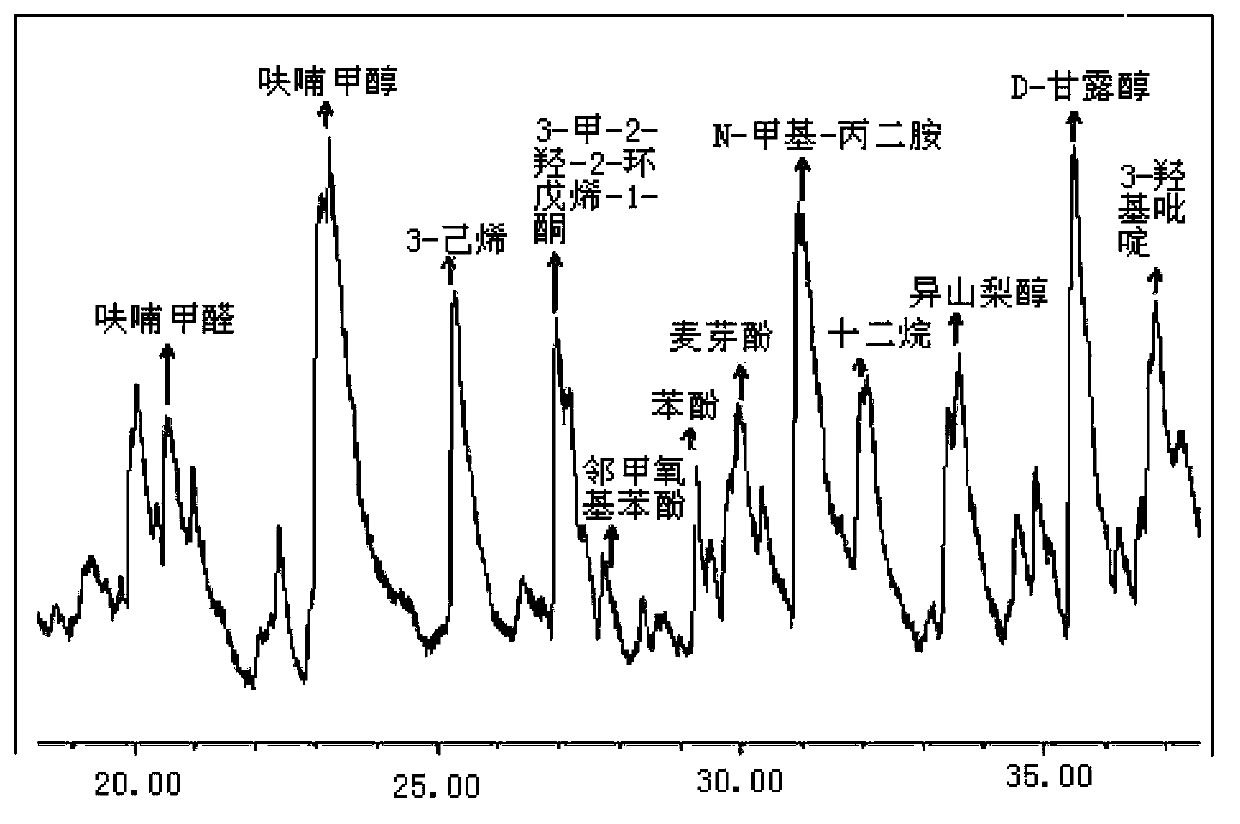

[0094] Take the wet distiller's grains and dry them at 100°C; crush the dried distiller's grains to particles with a particle size of 300um to obtain dried distiller's grains; add 0.05 tons of industrial FH-UDS catalyst to 1 ton of dried distiller's grains, FH- UDS catalyst was developed by Fushun Petrochemical Research Institute and mixed evenly. After that, send it to the cracking tank, and pass nitrogen gas, after 10 minutes. Heating, the temperature of the system was raised to 500°C, and the pyrolysis was maintained at this temperature for 100 minutes. The pyrolysis steam is condensed in an ice-water bath to obtain crude product bio-oil and pyrolysis gas. The remaining residue is pyrolysis residue, and the mass of bio-oil, pyrolysis gas and pyrolysis residue is about 0.39 tons, 0.27 tons, and 0.33 tons ...

Embodiment 2

[0097] Example 2 Production of bio-fuel or chemical raw materials, high calorific value gas or hydrogen and activated carbon by catalytic cracking of distiller's grains

[0098] Take wet distiller's grains and dry them at 100°C; crush the dried distiller's grains to particles with a particle size of 300um to obtain dried distiller's grains powder; add 0.05 tons of catalyst Ni-γ-Al to 1 ton of dried distiller's grains 2 o 3 ,well mixed. Afterwards, send it into the cracking tank, feed nitrogen gas, heat up after 10 minutes, raise the temperature of the system to 500°C, and keep it at this temperature for cracking for 100 minutes. The pyrolysis steam is condensed in an ice-water bath to obtain crude product bio-oil and pyrolysis gas. The remaining residue is pyrolysis residue, and the mass fractions of bio-oil, pyrolysis gas and pyrolysis residue are about 0.43 tons, 0.23 tons, and 0.33 tons, respectively.

[0099] The cracked gas is analyzed by gas chromatography: flammable ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com