Hydrogenation system for producing ultralow-sulfur diesel oil, and method thereof

A technology of ultra-low-sulfur diesel and hydrogenation system, which is applied in the field of hydrogenation system for the production of ultra-low-sulfur diesel, which can solve the problems of difficult production of ultra-low-sulfur diesel products, large investment, high energy consumption, etc. The effect of increasing the volume fraction and reducing the energy consumption and investment of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] Example specific conditions:

[0043] a) The raw material oil used is mixed diesel oil, and the total sulfur content is 0.9% in weight percentage, wherein straight-run diesel oil accounts for 85%, and catalytically cracked diesel oil accounts for 15%;

[0044] b) Hydrogen adopts reformed hydrogen, and the volume composition is, V%: H292 / C12.46 / C22.62 / C31.97 / iC40.30 / nC40.57 / C5+0.08; among them, C1~C5 refer to carbon one to C5 alkanes;

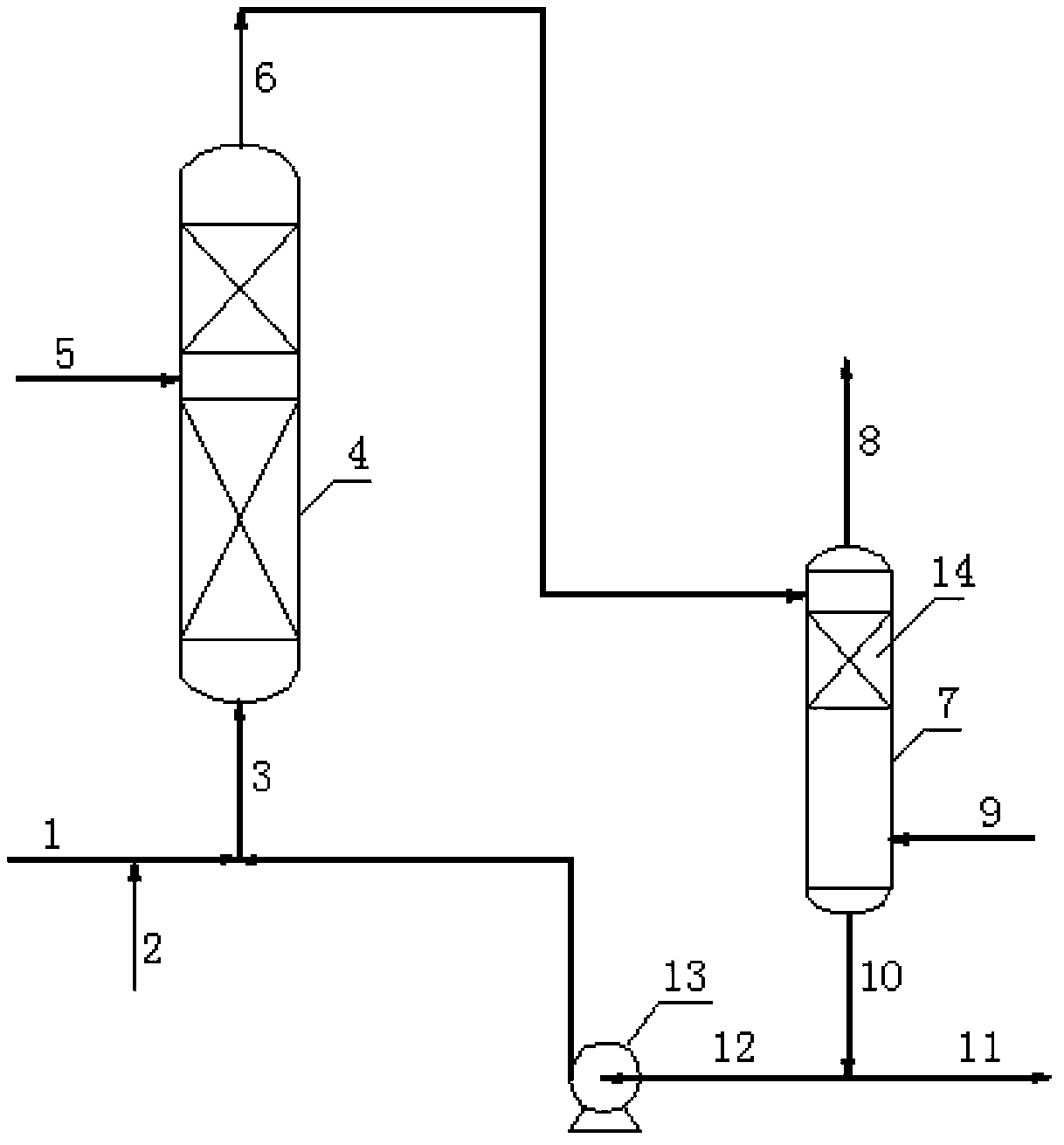

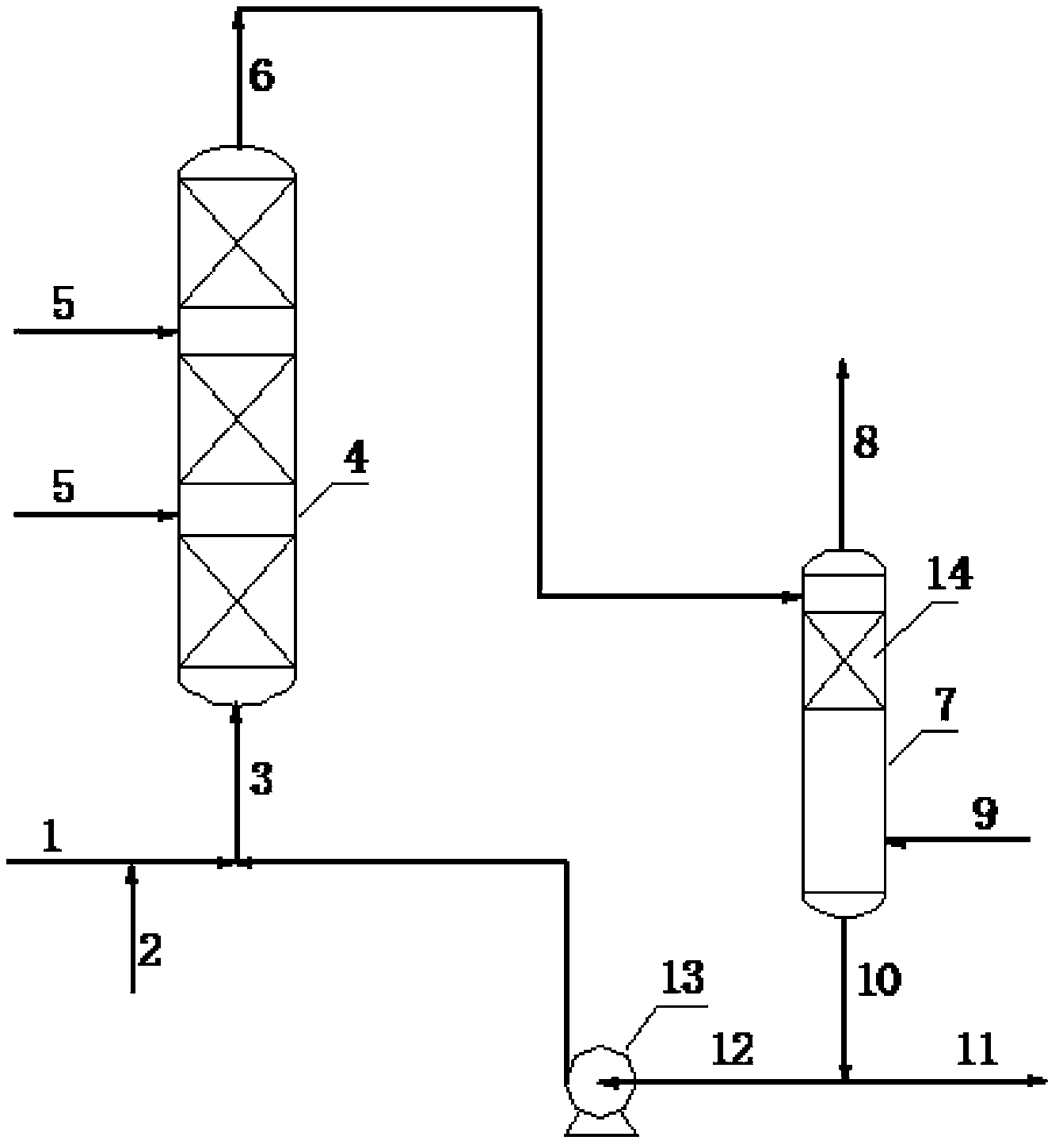

[0045] c) Three catalyst beds are set in the first-stage hydrogenation reaction zone; the weight ratio of circulating oil to feed oil is 1.5:1;

[0046] d) The operating conditions at the inlet of the first-stage hydrogenation reaction zone are: pressure 9.0MPa, temperature 350°C, and hourly space velocity of raw material liquid 2.5hr -1 ;

[0047] e) The average liquid phase volume fraction of the first-stage hydrogenation reaction zone is 90%;

[0048] f) The operating conditions of the second-stage hydrogenation reaction zone are: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com