Method for harmless resourceful treatment of antibiotic mushroom dregs

An antibiotic bacteria residue and resource utilization technology, applied in chemical instruments and methods, inorganic chemistry, hydrocarbon oil treatment, etc., can solve the problems of easy residues of antibiotics that endanger the environment and human health, affect treatment and resource utilization, and high energy consumption for operation. Achieve the effect of no antibiotic residues and secondary pollution, realizing resource-based treatment, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

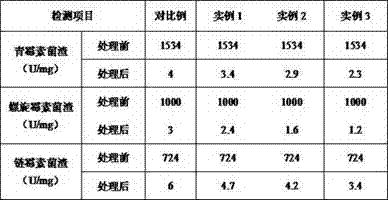

example 1

[0023] First, mix 5-6 tons of antibiotic residues to be treated with trypsin and phospholipase C in a mass ratio of 100:1:1, and keep warm for 7-10 hours at 35-37°C for enzymolysis. Spray the frozen enzymatic hydrolyzate with liquid nitrogen for 3 to 5 minutes, then put the frozen enzymatic hydrolyzate into a grinder and pulverize for 20 to 30 minutes to obtain a mixed pulverized product, and dig a 3m long, 2m wide, and deep For a 2m biogas digester, use cement to paint the bottom and wall of the pond evenly, and then lay a layer of polyethylene geomembrane on the bottom of the pond. Insulate and ferment at ~45°C for 5-7 days, collect the biogas produced during the fermentation process, and after the fermentation is completed, scoop out the fermentation product and filter, separate the filter residue and filtrate, and use the filtrate for later use, weigh 1-2kg of filter residue and 2-4L to remove Mix ionic water to obtain a mixed solution, then put the mixed solution into a h...

example 2

[0025]First, mix 5-6 tons of antibiotic residues to be treated with trypsin and phospholipase C in a mass ratio of 100:1:1, and keep warm for 7-10 hours at 35-37°C for enzymolysis. Spray the frozen enzymatic hydrolyzate with liquid nitrogen for 3 to 5 minutes, then put the frozen enzymatic hydrolyzate into a grinder and pulverize for 20 to 30 minutes to obtain a mixed pulverized product, and dig a 3m long, 2m wide, and deep For a 2m biogas digester, use cement to paint the bottom and wall of the pond evenly, and then lay a layer of polyethylene geomembrane on the bottom of the pond. Insulate and ferment at ~45°C for 5-7 days, collect the biogas produced during the fermentation process, and after the fermentation is completed, scoop out the fermentation product and filter, separate the filter residue and filtrate, and use the filtrate for later use, weigh 1-2kg of filter residue and 2-4L to remove Mix ionic water to obtain a mixed solution, then put the mixed solution into a hy...

example 3

[0027] First, mix 5-6 tons of antibiotic residues to be treated with trypsin and phospholipase C in a mass ratio of 100:1:1, and keep warm for 7-10 hours at 35-37°C for enzymolysis. Spray the frozen enzymatic hydrolyzate with liquid nitrogen for 3 to 5 minutes, then put the frozen enzymatic hydrolyzate into a grinder and pulverize for 20 to 30 minutes to obtain a mixed pulverized product, and dig a 3m long, 2m wide, and deep For a 2m biogas digester, use cement to paint the bottom and wall of the pond evenly, and then lay a layer of polyethylene geomembrane on the bottom of the pond. Insulate and ferment at ~45°C for 5-7 days, collect the biogas produced during the fermentation process, and after the fermentation is completed, scoop out the fermentation product and filter, separate the filter residue and filtrate, and use the filtrate for later use, weigh 1-2kg of filter residue and 2-4L to remove Mix ionic water to obtain a mixed solution, then put the mixed solution into a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com