Method for hydrofinishing biological crude oil by using high temperature gas cooled reactor

A technology of high-temperature gas-cooled reactor and bio-crude oil, applied in refining to remove heteroatoms, etc., can solve the problems of poor stability, poor thermal stability, large energy consumption and hydrogen consumption, and achieve improved water resistance and heat resistance, and simplified process The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

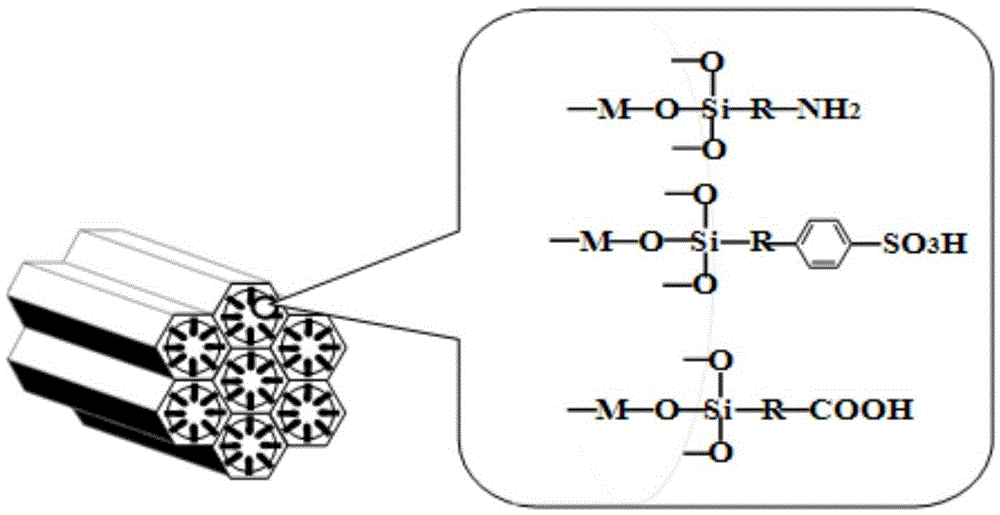

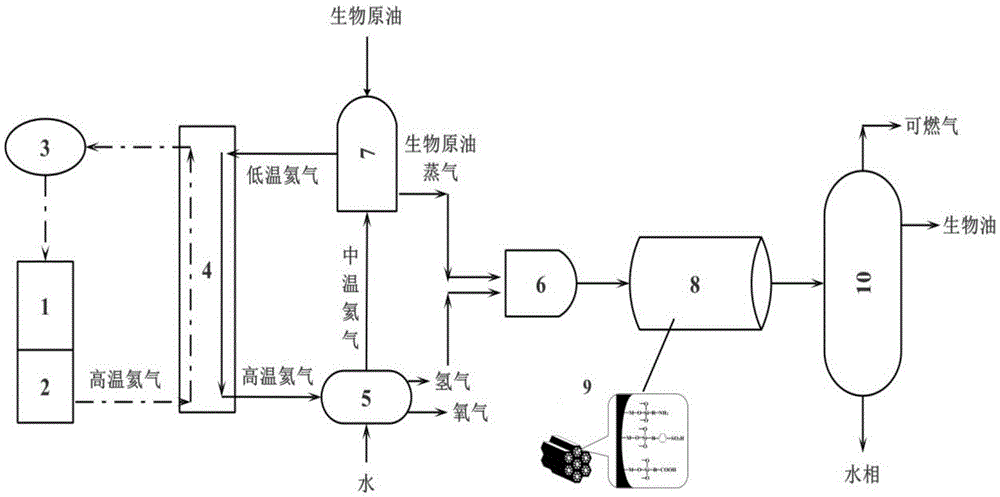

[0059] Embodiment 1. In crude oil by biomass cracking, the oil phase is 75%, the water phase is 25%, the oxygen content of the oil phase is 30%, and the calorific value is 22MJ / kg. Bio-oil vapor and hydrogen (the mass ratio of the two is 100:7) are mixed and then enter the catalytic hydrogenation fixed-bed reactor 8. The hydrogenation reaction temperature is 350°C and the hydrogen pressure is 15MPa. The catalyst is mesoporous molecular sieve SBA-15 doped with Pt and added amino organic functional groups. The oil phase obtained after the hydrogenation reaction is completed and condensed and separated accounts for 80%, the oxygen content of the oil phase is 2.5%, the calorific value is 39MJ / kg, the gas phase accounts for 3%, and the rest is the water phase.

Embodiment 2

[0060] Embodiment 2, in bio-crude oil, the oil phase is 75% by mass, the water phase is 25%, the oxygen content of the oil phase is 30%, and the heat value is 22MJ / kg. Bio-oil vapor and hydrogen (the mass ratio of the two is 100:6) are mixed and then enter the catalytic hydrogenation fixed-bed reactor 8, the hydrogenation reaction temperature is 280°C, and the hydrogen pressure is 4MPa. The catalyst is mesoporous molecular sieve SBA-15 doped with Pd-Co and grafted with amino and carboxyl organic functional groups. The oil phase obtained after the hydrogenation reaction is completed and condensed and separated accounts for 80%, the oxygen content of the oil phase is 0.5%, the calorific value is 41.2MJ / kg, the gas phase accounts for 4%, and the rest is the water phase.

Embodiment 3

[0061] Embodiment 3, the mass ratio of bio-crude oil is 75%, the water phase is 25%, the oxygen content of the oil phase is 30%, and the calorific value is 22MJ / kg. Bio-oil vapor and hydrogen (the mass ratio of the two is 100:9) are mixed and then enter the catalytic hydrogenation fixed-bed reactor 8. The hydrogenation reaction temperature is 320°C and the hydrogen pressure is 10MPa. The catalyst is mesoporous molecular sieve SBA-15 doped with Pt-Ni and grafted amino and sulfonic acid organic functional groups at the same time. The oil phase obtained after the hydrogenation reaction is completed and condensed and separated accounts for 80%, the oxygen content of the oil phase is 1.5%, the calorific value is 40MJ / kg, the gas phase accounts for 5%, and the rest is the water phase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com