Biofuel oil processing device

A technology for processing equipment and fuel oil, which is applied in the fields of fuel, petroleum industry, liquid carbon-containing fuel, etc., can solve the problems of poor quality of biofuel oil, unsatisfactory impurity removal effect, outdated processing equipment, etc. Automatic separation and collection, good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with specific embodiment, further illustrate the present invention.

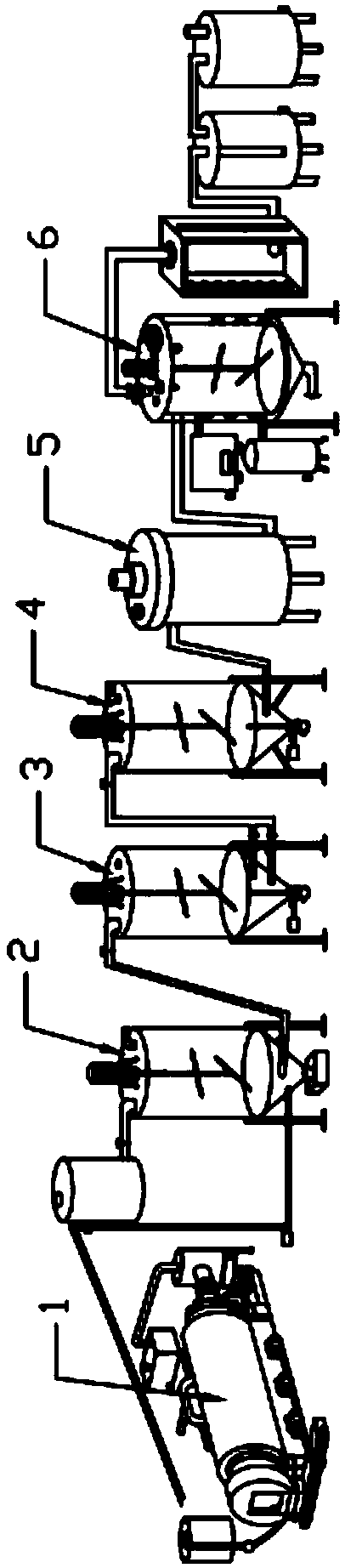

[0028] like Figure 1-7 As shown, a biofuel oil processing equipment includes a separation and pretreatment equipment 1 , a degumming device 2 , a deacidification device 3 , a decolorization device 4 , a dehydration device 5 and a deodorization device 6 connected in sequence.

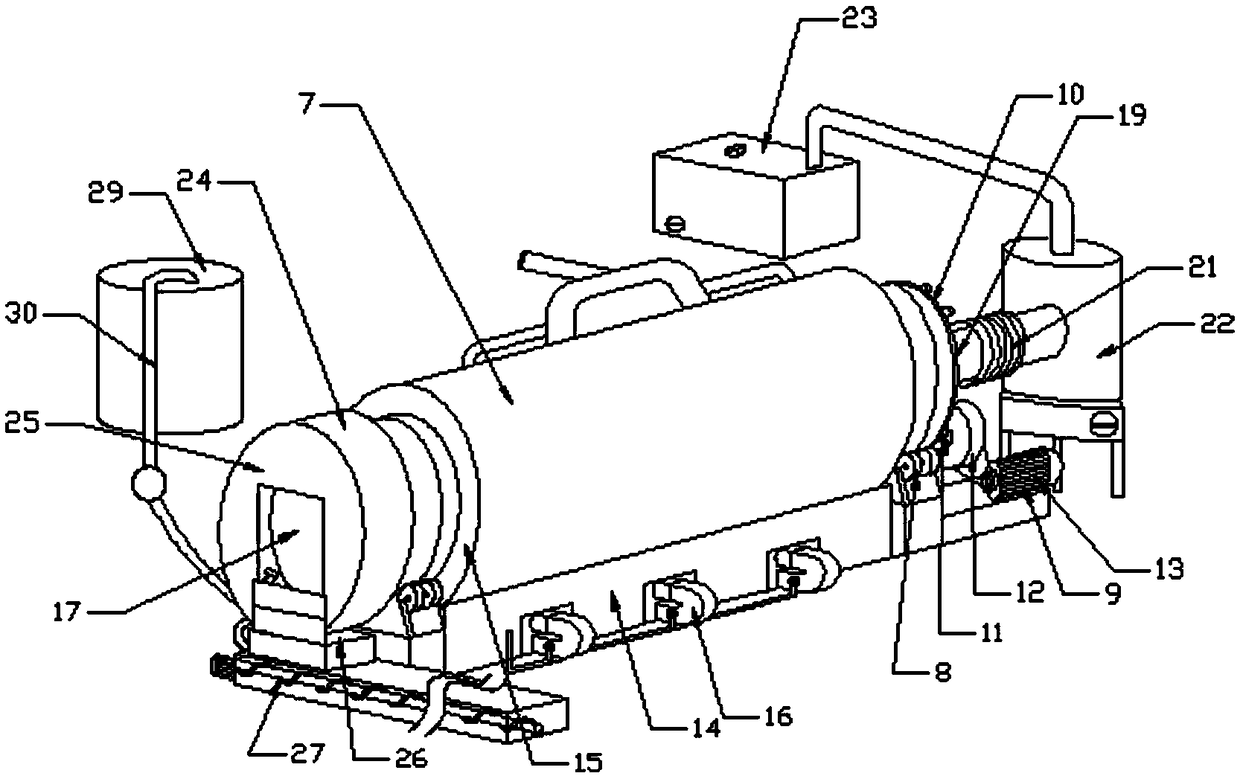

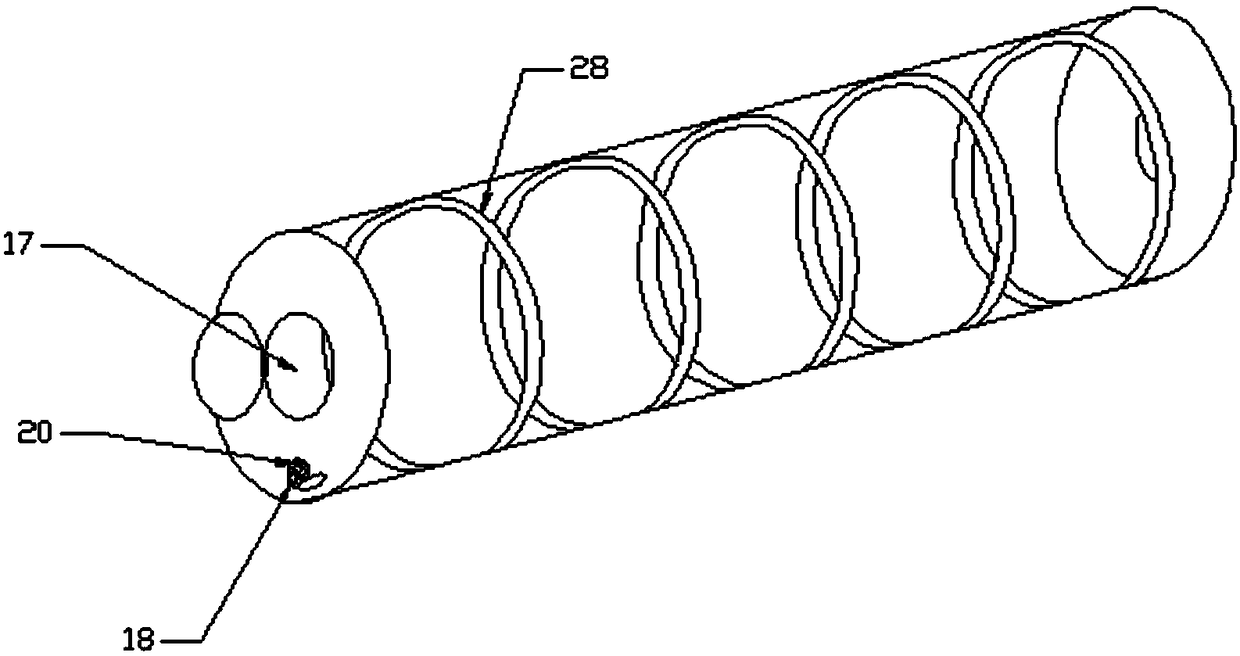

[0029] like Figure 2-3As shown, the separation pretreatment equipment 1 includes a pyrolysis furnace body 7, the pyrolysis furnace body 7 is a rotary furnace arranged horizontally, and a rotating supporting wheel 8 is arranged under both ends of the pyrolysis furnace body 7, and one end outside It is connected with the rotary drive device 9 . The driving device 9 includes a rolling ring 10 arranged on the outer circumference of the pyrolysis furnace body 7 and a driving wheel 11 for driving the rolling ring 10 to rotate. The driving wheel 11 is connected with a reducer 12 and a motor 13 . A heating devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com