Method and an apparatus for refining biomass fuel oil by hydration catalysis means

A biomass and fuel oil technology, applied in fuel, liquid carbon-containing fuel, petroleum industry, etc., can solve problems such as process risk, unstable composition, and unstable function, and achieve the effect of process simplification and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

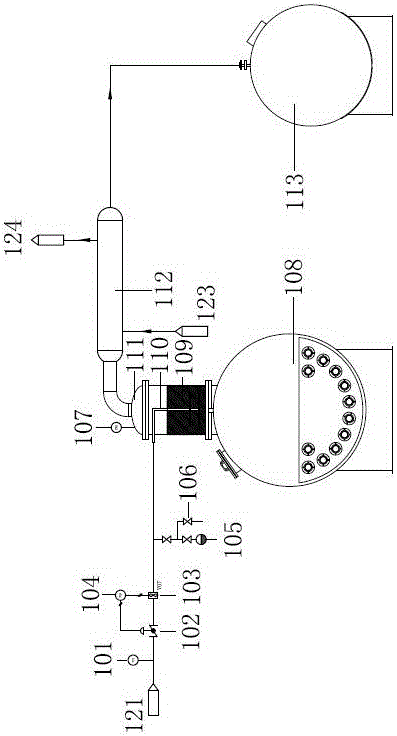

[0019] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

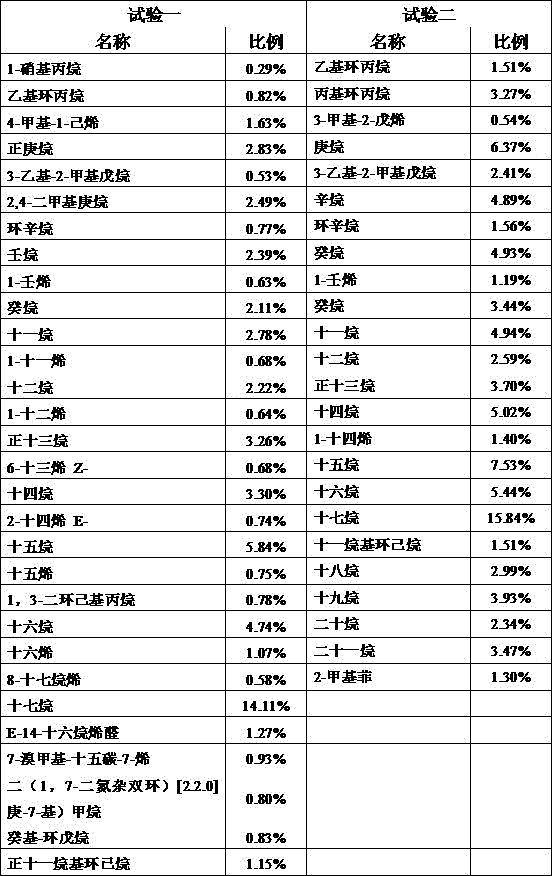

[0020] Carboxyl groups and hydroxyl groups of fatty acids, unsaturated hydrocarbons and hydroxyl groups, unsaturated hydrocarbons and hydrogen ions react on a suitable catalytic surface at a certain catalyst surface temperature (120-300°C) to generate alkanes, aromatic hydrocarbons, ketones, aldehydes, components such as esters. According to this theory, the present invention designs the hydration catalytic cracking reaction mode, the basic principle of which is: when the steam of fatty acids and unsaturated hydrocarbons (waste animal and vegetable oils and plastic depolymerized liquefied oil) passes through the SZM molecular sieve catalyst, with the change of catalyst temperature, Long-chain oil and gas molecules are broken into short-chain molecules to varying degrees. When the surface temperature of the catalyst reaches 280°C, C24 chain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com