Method for producing silicon dioxide by using gas phase process

A silicon dioxide and production method technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve problems such as high cost and reduce production cost, and achieve the effects of reducing raw material cost, high quality, significant economic and environmental significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

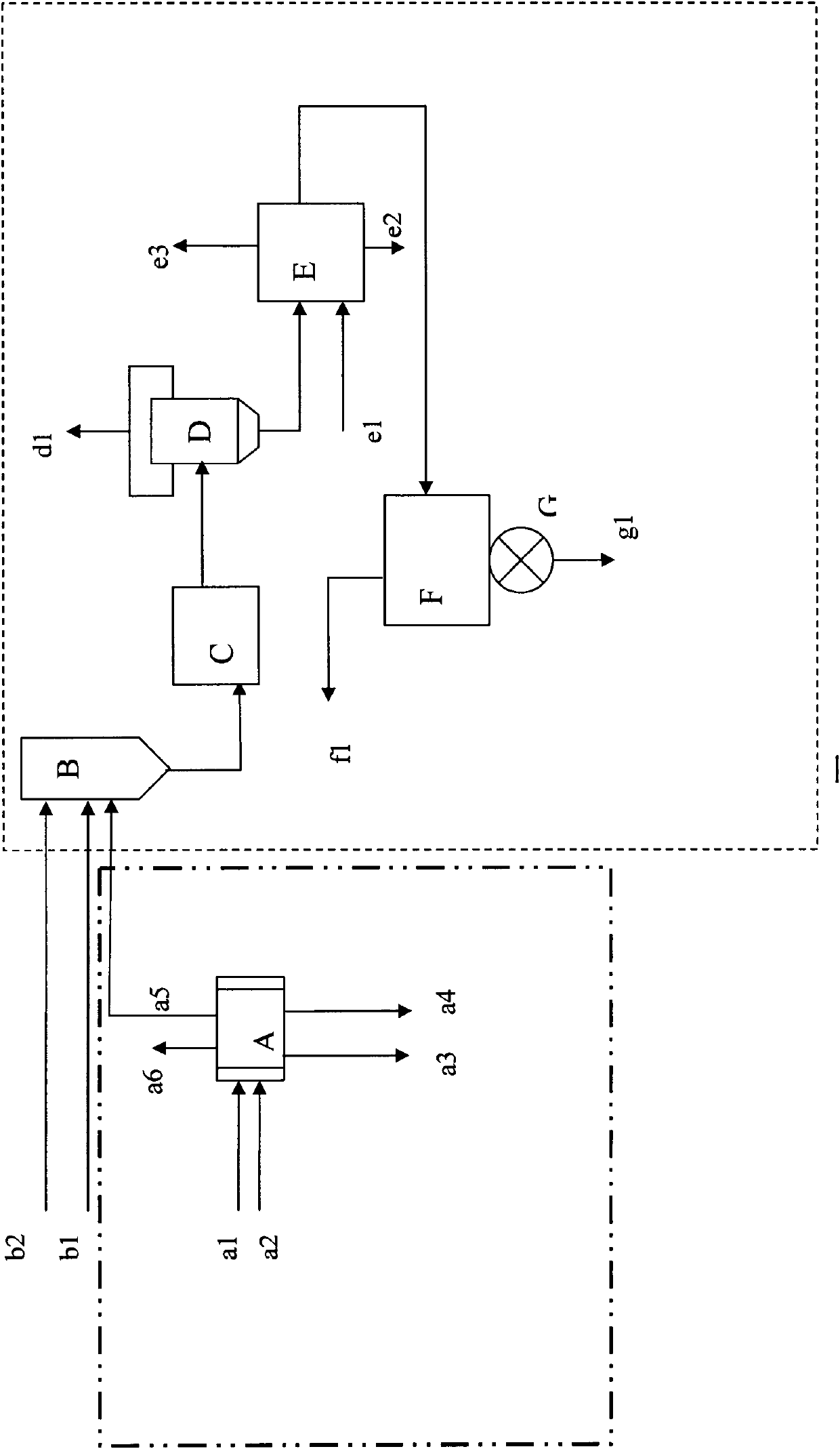

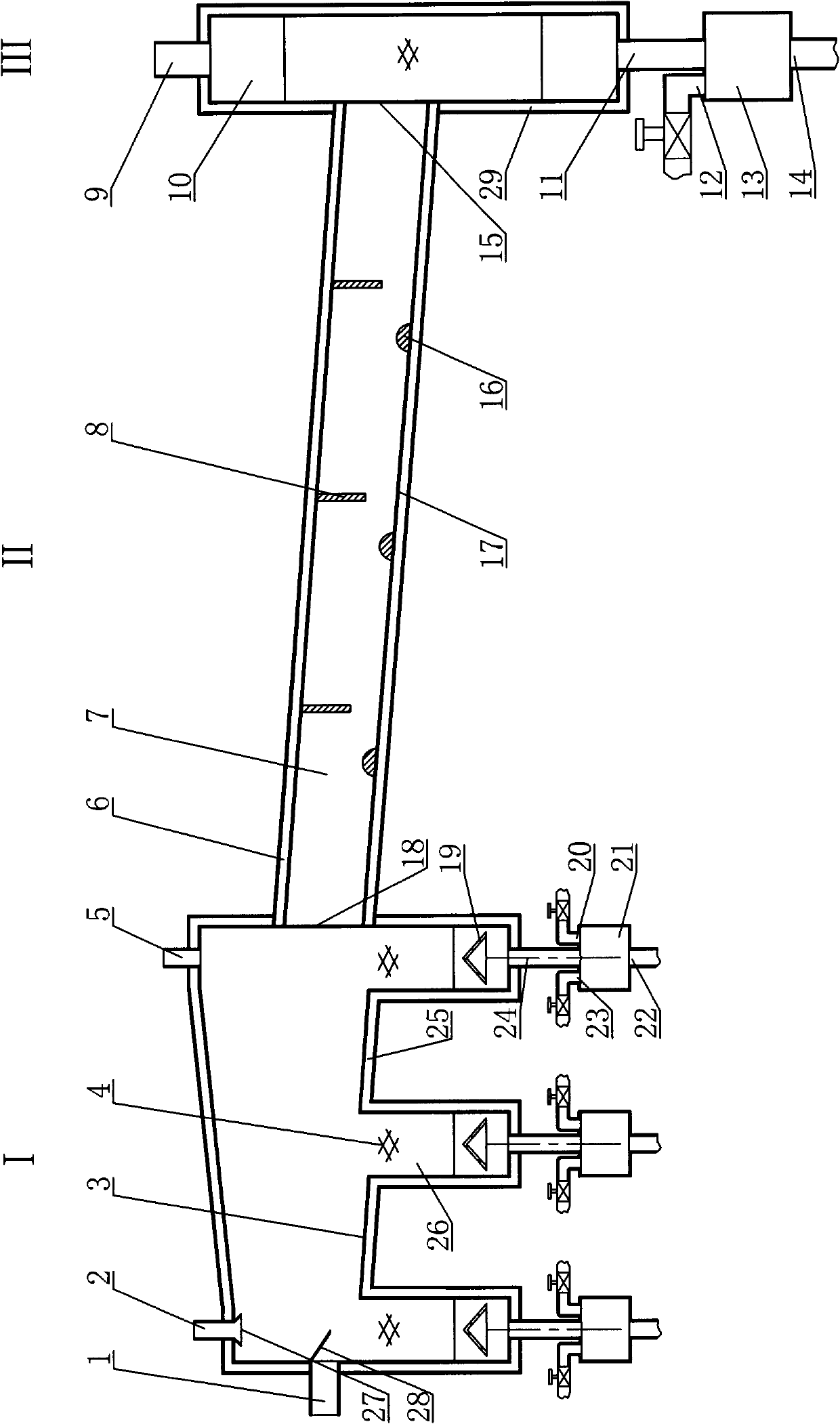

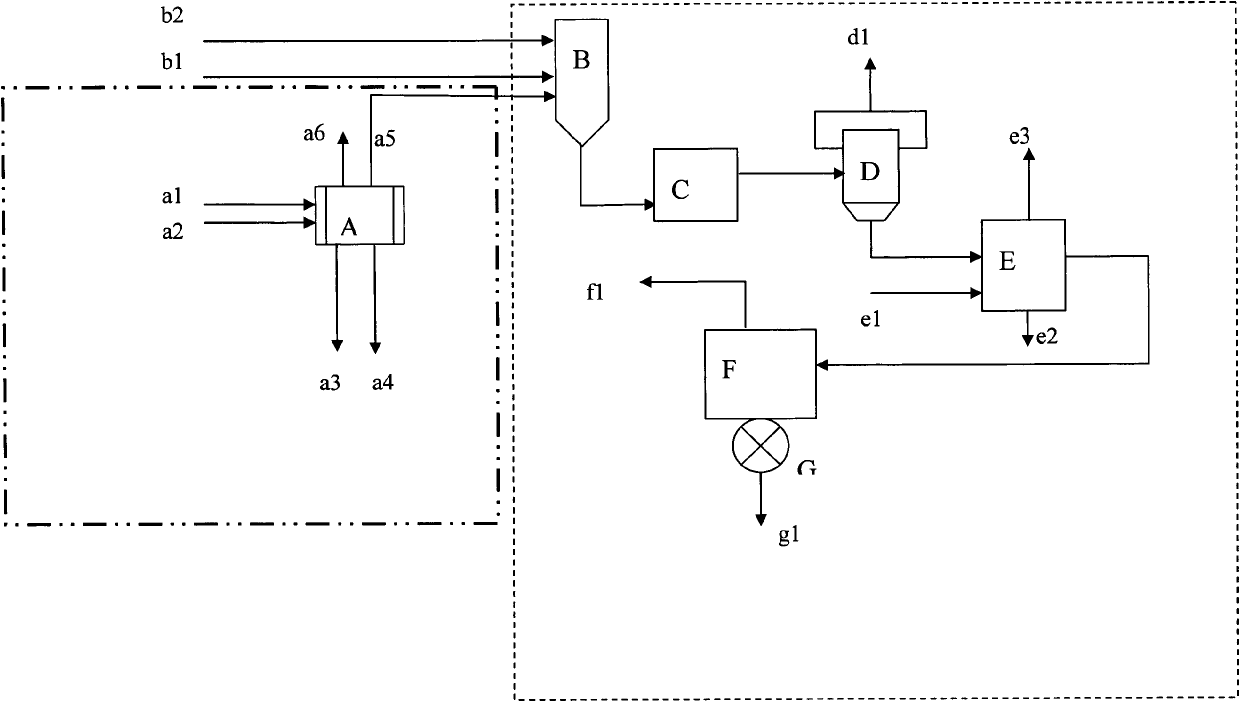

Method used

Image

Examples

Embodiment 1

[0039] Press hydrogen: silicon tetrachloride: air=1: 1.6 * 10-3: 1.5 (molar ratio) ratio, will contain silicon tetrachloride 90.5% aforementioned raw material silicon tetrachloride, hydrogen, air three kinds of materials in the aforementioned manner into the combustion reactor 2. go through figure 1 Obtain product analysis (according to Q / SHG19-2008) result after the technological process shown:

[0040] Specific surface area: 142m 2 / g

[0041] PH value: 3.8

[0042] Apparent density: 53g / l.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com