Waste foundry sand regeneration method

A technology for foundry waste sand and fine sand, which is applied in the direction of foundry molding equipment, cleaning/processing machinery for casting mold materials, manufacturing tools, etc., and can solve the problem that inorganic coated sand and organic resin sand cannot be regenerated and recycled, and the lack of recycling technology , Huge wet recycling equipment, etc., to reduce the purchase cost and the cost of waste sand discharge and stacking, avoid environmental damage, save warehouse construction and occupation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

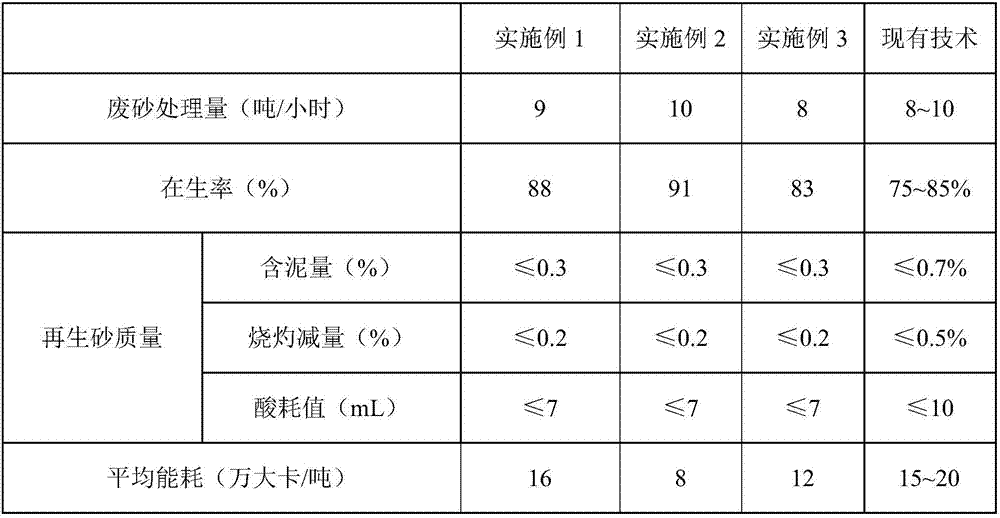

Embodiment 1

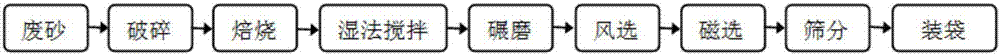

[0023] Such as figure 1 As shown, the method for the regeneration of foundry waste sand of the present embodiment is carried out according to the following steps:

[0024] (1) Foundry waste sand crushing: the inorganic coated sand and organic resin sand cores are crushed to become fine sand, which is easy to enter the roasting furnace, and the crushed fine sand can pass through the 3mm×3mm sieve.

[0025] (2) Roasting: Roast the fine sand crushed in step (1) at 340°C to remove the inert film on the surface of the inorganic coated sand, and then bake at 650°C to completely burn the organic matter in the waste sand.

[0026] (3) Wet mixing: move the fine sand roasted in step (2) into a stirring tank equipped with 0.28mol / L hydrochloric acid solution and stir, on the one hand, it cools down the sand, and in addition neutralizes the alkaline substances in the sand , the fine sand and waste liquid are separated by the sand-water separator, the waste liquid is treated and discharge...

Embodiment 2

[0031] The difference between the operating steps of the method for the regeneration of foundry waste sand of this embodiment and that of Embodiment 1 is that in this embodiment, the raw material for processing in step (1) is an inorganic coated sand core, and the temperature used for roasting in step (2) It is 360 ℃, and other operations are identical with embodiment 1.

Embodiment 3

[0033] The difference between the operating steps of the method for the regeneration of foundry waste sand of this embodiment and that of Example 1 is that in this embodiment, the raw material for processing in step (1) is an organic resin sand core, and the temperature used for roasting in step (2) is 350°C, other operations are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com