Preparation method of propane catalytic combustion composite oxide catalyst and application of catalyst

A composite oxide, catalytic combustion technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, combustion method, etc., to achieve the effect of low cost, good stability and complete combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

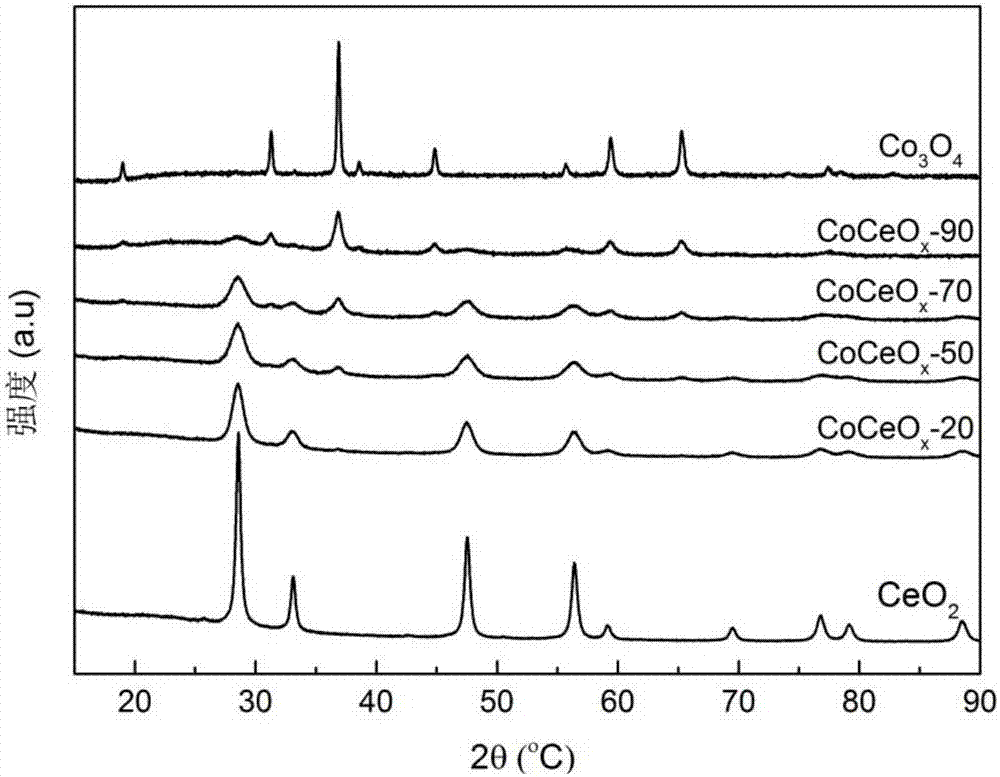

[0020] Embodiment 1: the preparation method of propane catalytic combustion catalyst of the present invention

[0021] a. 4.3422g (0.01mol) Ce(NO 3 ) 3 ·6H 2 O was dissolved in 20 mL of deionized water to form solution A, and 3.1521 g of citric acid was dissolved in 10 mL of deionized water to form solution B.

[0022] b. Mix solution A and solution B, and stir in a water bath at 60°C for 1 hour to obtain solution C.

[0023] c. Put solution C on a rotary evaporator, heat to 60° C., and rotary evaporate for 90 minutes to obtain gel-like substance D.

[0024] d. Place the substance D in an oven at 90°C for 10 hours at a constant temperature.

[0025] e. Put the product of the above step d in a muffle furnace at 300° C. for 1 hour to decompose citric acid to obtain a dry powder.

[0026] f. Calcining the above dry powder in a muffle furnace at 550°C for 4h to obtain pure cerium oxide catalyst CeO 2 .

Embodiment 2

[0027] Embodiment 2: the preparation method of propane catalytic combustion catalyst of the present invention

[0028] a. 3.4738g (8mmol) Ce (NO 3 ) 3 ·6H 2 O and 0.5821g (2mmol) Co(NO 3 ) 2 ·6H 2 O (molar ratio Co / (Ce+Co)=20%) was dissolved in 20 mL of deionized water to form solution A, and 3.1521 g of citric acid was dissolved in 10 mL of deionized water to form solution B.

[0029] b. Mix solution A and solution B, and stir in a water bath at 60°C for 1 hour to obtain solution C.

[0030] c. Transfer solution C to a rotary evaporator, slowly heat to 60° C., and rotary evaporate for 90 minutes to obtain gel-like substance D.

[0031] d. Place the substance D in an oven at 90°C for 10 hours at a constant temperature.

[0032] e. Put the product of the above step d in a muffle furnace at 300° C. for 1 hour to decompose citric acid to obtain a dry powder.

[0033] f. Put the above dry powder in a muffle furnace at 550°C for 4 hours to obtain the cerium-cobalt composite...

Embodiment 3

[0034] Embodiment 3: Prepare the cerium-cobalt composite oxide catalyst with molar ratio Co / (Co+Ce)=50% according to the method of embodiment 2, denoted as CoCeO x -50.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com