Metal ion doped manganese oxide catalyst, preparation method and use thereof

A technology of metal ions and catalysts, which is applied in the field of metal ion-doped manganese oxide catalysts, can solve problems such as differences in catalytic performance and structure, and achieve the best catalytic combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

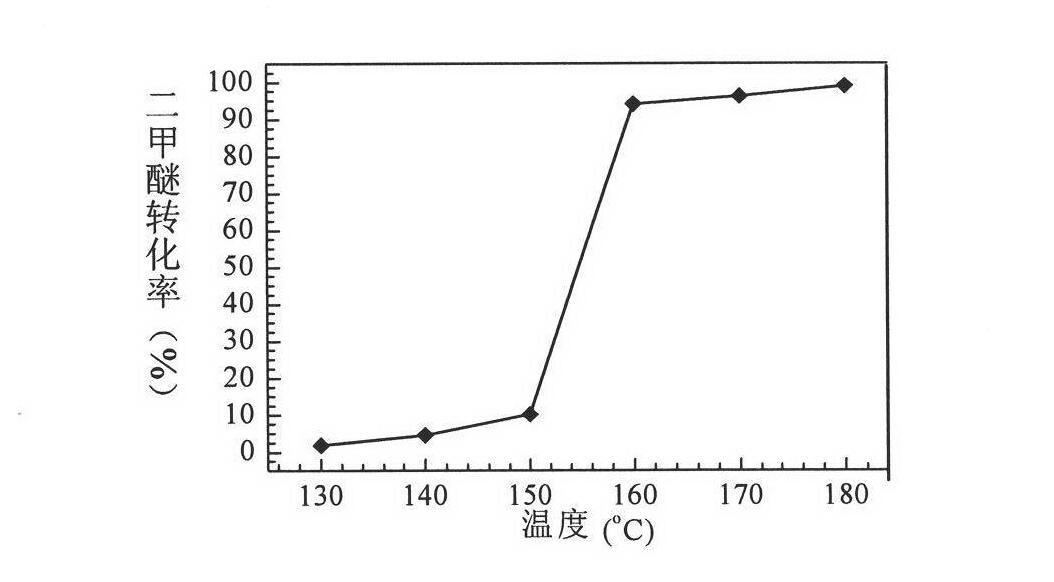

Embodiment 1

[0018] In a 40°C water bath, Bir-type manganese oxide and Ce(NO 3 ) 3 According to the Ce / Mn molar ratio of 1%, mixed evenly, stirred vigorously, washed and filtered, and baked at 110°C for 12 hours to obtain a black solid powder. Ce-doped manganese oxide is obtained, and its crystal structure is mainly Bir-type manganese oxide. The obtained catalyst is crushed and sieved to 40-60 meshes after being pressed into tablets for use.

Embodiment 2

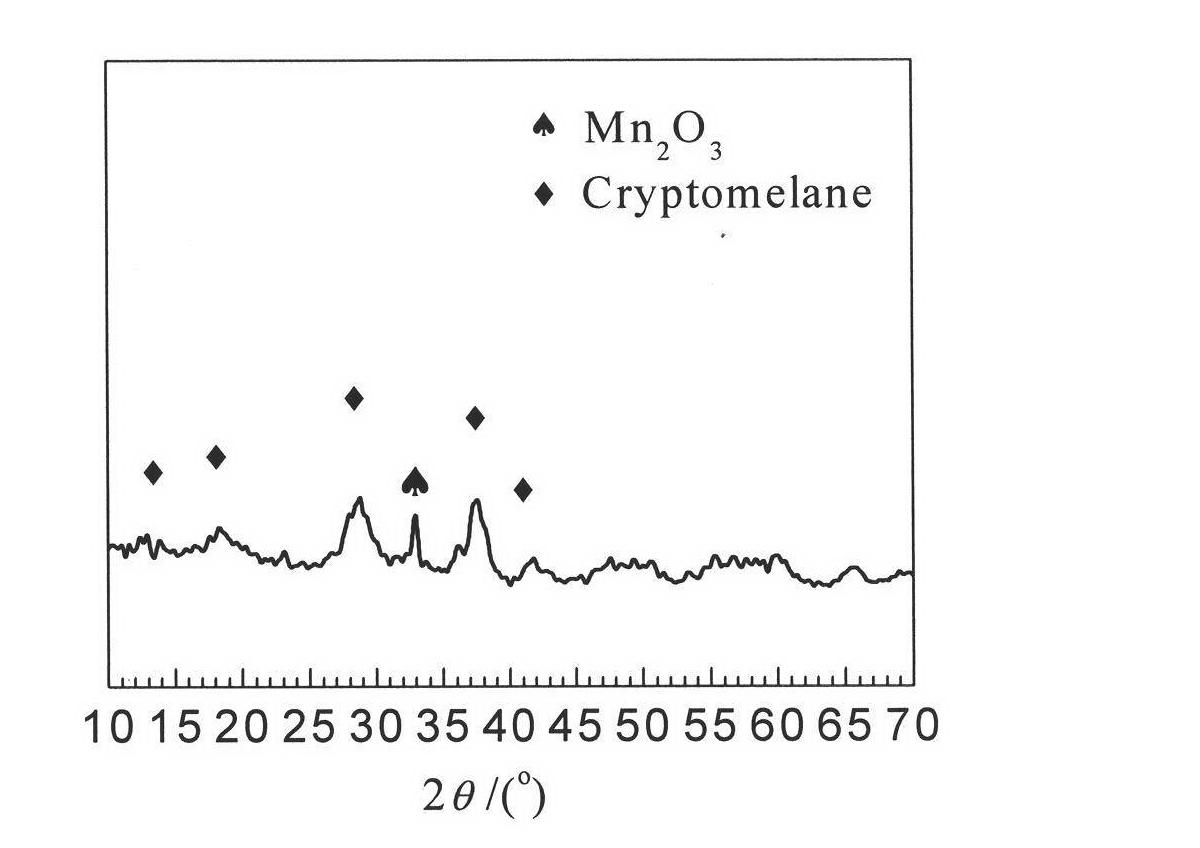

[0020] In a 60°C water bath, Bir-type manganese oxide and Ce(NO 3 ) 3 Mix evenly according to Ce / Mn molar ratio of 5%, stir vigorously, wash and filter, and bake at 110°C for 12 hours to obtain a black solid powder. The powder is roasted at 700°C for 20 hours at a rate of 4°C / min in an air atmosphere. Ce-doped manganese oxide was obtained. Its crystal structure is mainly Mn 2 o 3 . The obtained catalyst is crushed and sieved to 40-60 meshes after being pressed into tablets for use.

Embodiment 3

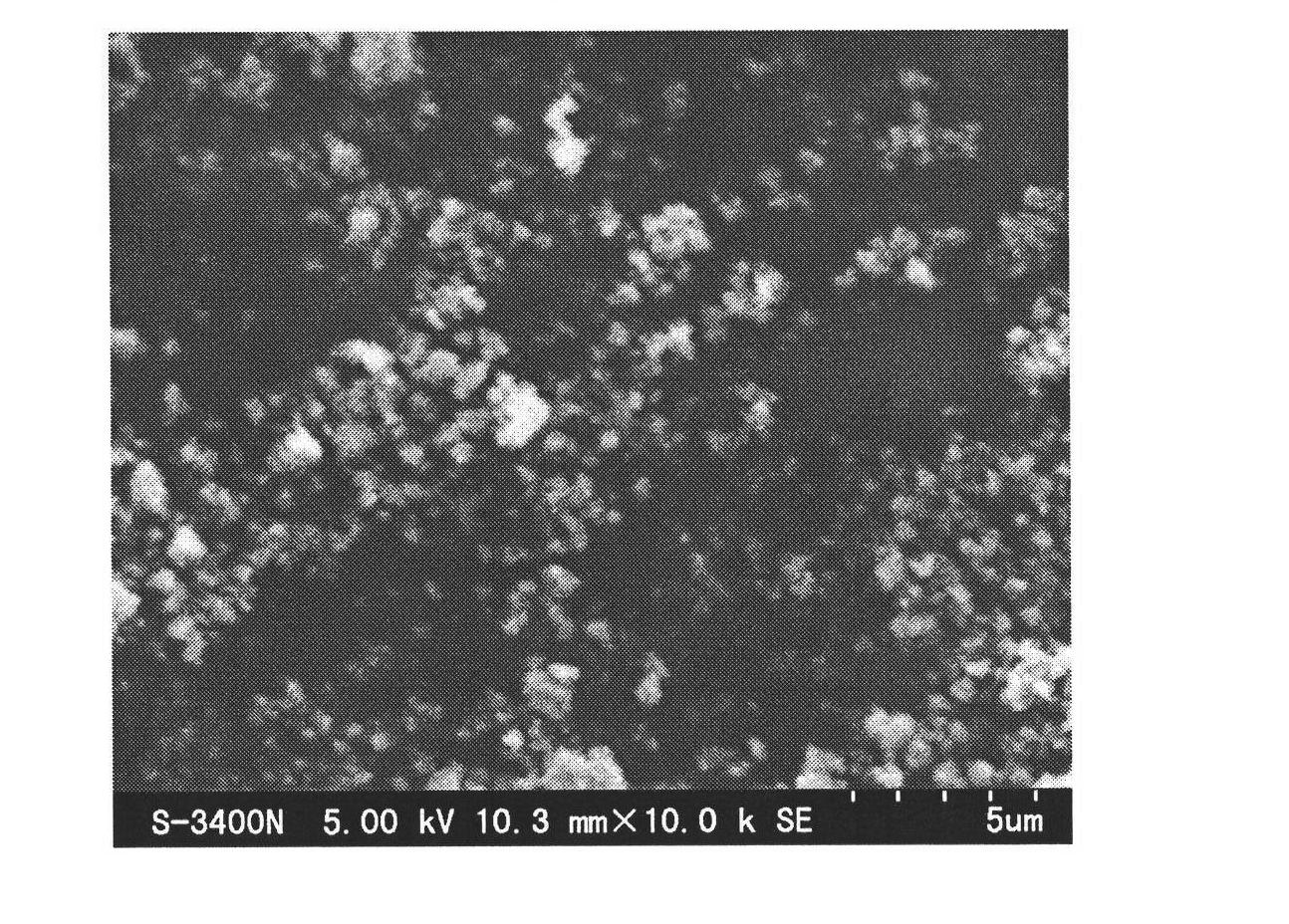

[0022] In a 60°C water bath, Bir-type manganese oxide and Ce(NO 3 ) 3 Mix evenly according to Ce / Mn molar ratio of 7%, stir vigorously, wash and filter, and bake at 110°C for 12 hours to obtain a black solid powder. The powder is roasted at a rate of 4°C / min to 500°C for 5 hours in an air atmosphere. Ce-doped manganese oxide was obtained. Its crystal structure is mainly Cry type manganese oxide. The obtained catalyst is crushed and sieved to 40-60 meshes after being pressed into tablets for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com