Stone-like coating for outer wall

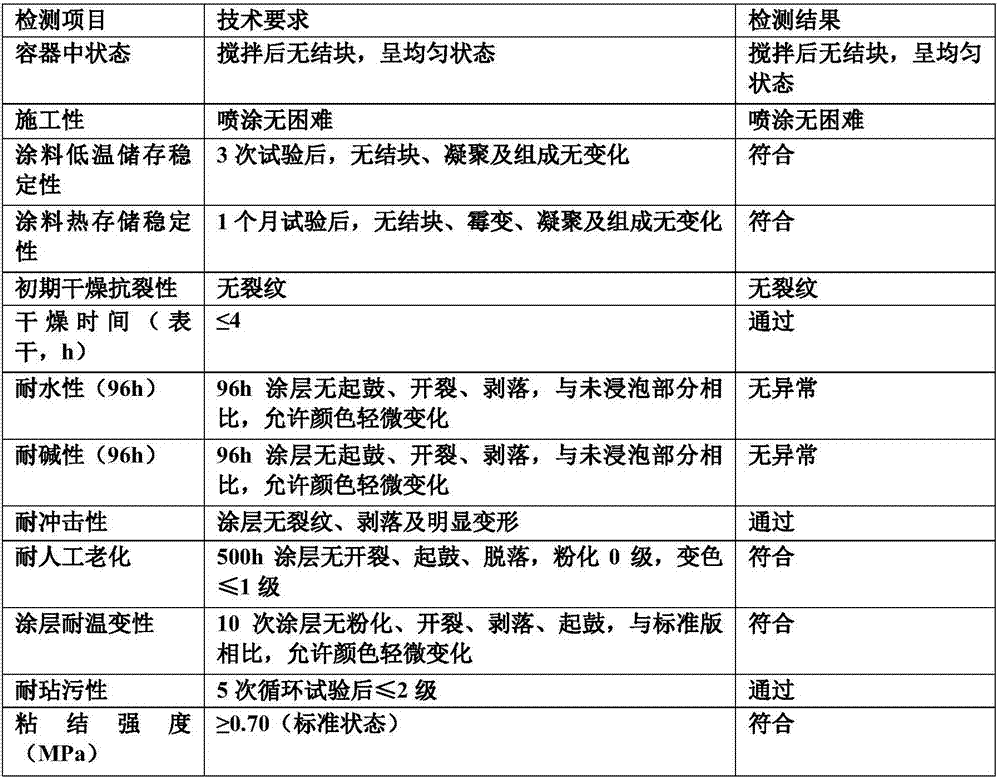

A real stone paint and coating technology, applied in the field of wall coatings, can solve the problems of poor water resistance of the coating, the paint film is not easy to dry, and the film is not formed in time, and achieves the effect of bright luster, easy construction and operation, and strong three-dimensional effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of real stone paint coating for exterior walls, its composition includes the following components in parts by mass: 100 parts of emulsion (silicon acrylic emulsion and styrene acrylic emulsion according to the ratio of 6:4), 300 parts of colored sand, thickener carboxyl 7 parts of methyl cellulose (viscosity of 3500mPa.s), 0.5 parts of pH regulator AMP-95, 8 parts of alcohol ester twelve film-forming aids, 0.5 parts of paint dispersant Dispersant-5040, and 0.5 parts of defoamer SN-NXZ 0.5 parts, 0.5 parts of paint antiseptic and bactericide of model BIT10, 5 parts of water-repellent agent and 150-200 parts of deionized water.

[0029] Described real stone varnish coating for exterior wall is prepared by the following method:

[0030] (1) Pretreatment of colored sand

[0031]The composition of colored sand is calculated by mass percentage: 80-120 mesh snowflake white 60%, 80-120 mesh medium yellow 20%, 80-120 mesh cream yellow 10%, 120-180 mesh tiger skin yellow ...

Embodiment 2

[0036] A kind of real stone paint coating for exterior walls, its composition includes the following components in parts by mass: 200 parts of emulsion (silicon acrylic emulsion and styrene acrylic emulsion according to the ratio of 8:2), 400 parts of colored sand, thickener carboxylate 15 parts of methyl cellulose (viscosity of 4000mPa.s), 1 part of pH regulator AMP-95, 15 parts of alcohol ester twelve film-forming aids, 1 part of paint dispersant Dispersant-5040, 1 part of defoamer SN-NXZ 1 part, 1 part of paint antiseptic and bactericide of model BIT10, 10 parts of water repellent and 200 parts of deionized water.

[0037] Described real stone varnish coating for exterior wall is prepared by the following method:

[0038] (1) Pretreatment of colored sand

[0039] The composition of colored sand is calculated by mass percentage: 80-120 mesh snowflake white 60%, 80-120 mesh medium yellow 25%, 80-120 mesh cream yellow 10%, 80-120 mesh rosin yellow 5%.

[0040] The above-ment...

Embodiment 3

[0044] A kind of real stone paint coating for exterior walls, its composition includes the following components in parts by mass: 200 parts of emulsion (silicon acrylic emulsion and styrene acrylic emulsion according to the ratio of 7:3), 300 parts of colored sand, thickener carboxylate 10 parts of methyl cellulose (viscosity of 4000mPa.s), 0.8 parts of pH regulator AMP-95, 12 parts of alcohol ester twelve film-forming aids, 1 part of paint dispersant Dispersant-5040, and 1 part of defoamer SN-NXZ 1 part, 1 part of BIT10 paint antiseptic and bactericide, 8 parts of water repellent and 180 parts of deionized water.

[0045] Described real stone varnish coating for exterior wall is prepared by the following method:

[0046] (1) Pretreatment of colored sand

[0047] The composition of colored sand is calculated by mass percentage: 80-120 mesh snowflake white 60%, 80-120 mesh medium yellow 10% and 200 mesh cream yellow 30%.

[0048] The above-mentioned colored sand is spray-drie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com