A kind of pet non-woven fabric-based composite lithium-ion battery diaphragm with nanopore and preparation method thereof

A non-woven-based, ion battery technology, applied in the field of electrochemical power supply, can solve problems such as poor thermal stability, membrane melting deformation, short circuit, etc., and achieve the effects of excellent electrochemical performance, easy operation and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also includes a preparation method of a PET non-woven fabric-based composite lithium-ion battery diaphragm with a nanopore, comprising the following steps:

[0030] Under the condition of water bath heating, high molecular polymer is dissolved in deionized water, obtains high molecular polymer solution; The mass ratio of described high molecular polymer and deionized water is 0.5~30:100, and the temperature of water bath heating is 25~95°C, the heating time in a water bath is 2~12 hours; the high molecular polymer is polyvinyl alcohol or sodium hydroxymethyl cellulose;

[0031] Soak the hydrophilic PET non-woven fabric substrate in the step In the obtained high molecular polymer solution, ultrasonically disperse the hydrophilic PET non-woven fabric substrate in the high molecular polymer solution, and then keep the water bath heating under vacuum conditions for 1 to 6 hours to obtain the hydrophilic PET non-woven fabric after vacuum impregnati...

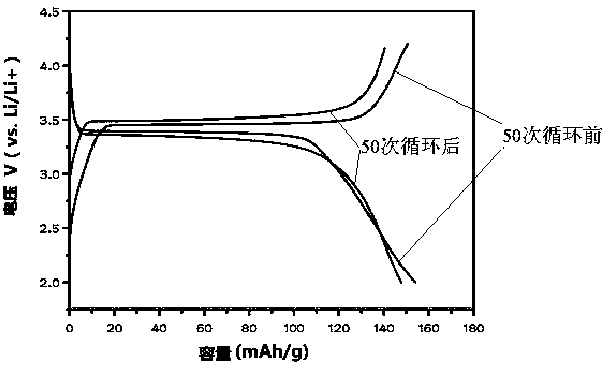

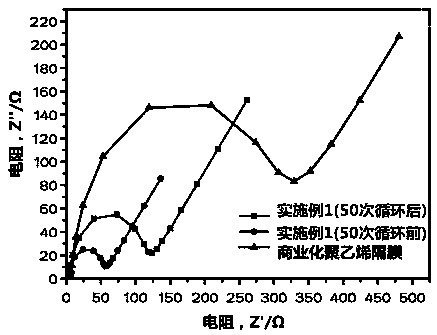

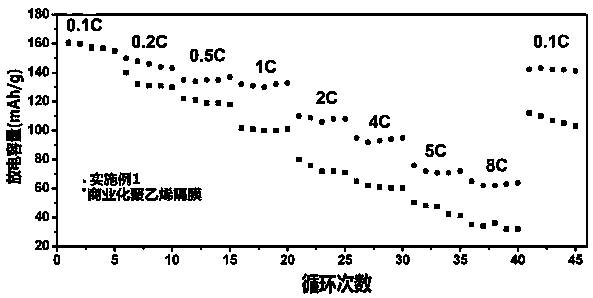

Embodiment 1

[0041] A PET non-woven fabric-based composite lithium-ion battery diaphragm with a nanopore size, comprising a hydrophilic PET non-woven fabric substrate and polyvinyl alcohol, the hydrophilic PET non-woven fabric substrate is evenly distributed with micron-sized pores , with a porosity of 68%, the polyvinyl alcohol is filled in the pores of the hydrophilic PET non-woven fabric substrate, the pores of the hydrophilic PET non-woven fabric substrate are reduced to nanoscale, and the hydrophilic PET non-woven fabric The surface density of the cloth substrate is 20g / m 2 , the fiber fineness is 1.3D, the thickness is 45μm, and the air permeability under the condition of 124Mpa is 4000mm / s.

Embodiment 2

[0043] A PET non-woven fabric-based composite lithium-ion battery diaphragm with nanopores, comprising a hydrophilic PET non-woven base material and sodium hydroxymethyl cellulose, on which micron-sized Small pores, the porosity is 52%, the high molecular polymer is filled in the small pores of the hydrophilic PET non-woven fabric substrate, and the small pores of the hydrophilic PET non-woven fabric substrate are reduced to nanoscale, hydrophilic The surface density of the water PET non-woven substrate is 30g / m 2 , the fiber fineness is 1.7D, the thickness is 60μm, and the air permeability under the condition of 124Mpa is 2753mm / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com