Flowing phase-change energy storing type falling-film evaporating heat pump unit

A technology of heat pump units and falling film evaporation, which is applied in heat pumps, evaporation, horizontal tube evaporators, etc., can solve problems such as unbalanced use of cold/heat in two directions, constraints on the properties of energy storage materials, and difficulty in improving heat exchange efficiency, etc., to achieve structural Reasonable, ensure uniformity, improve the effect of heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

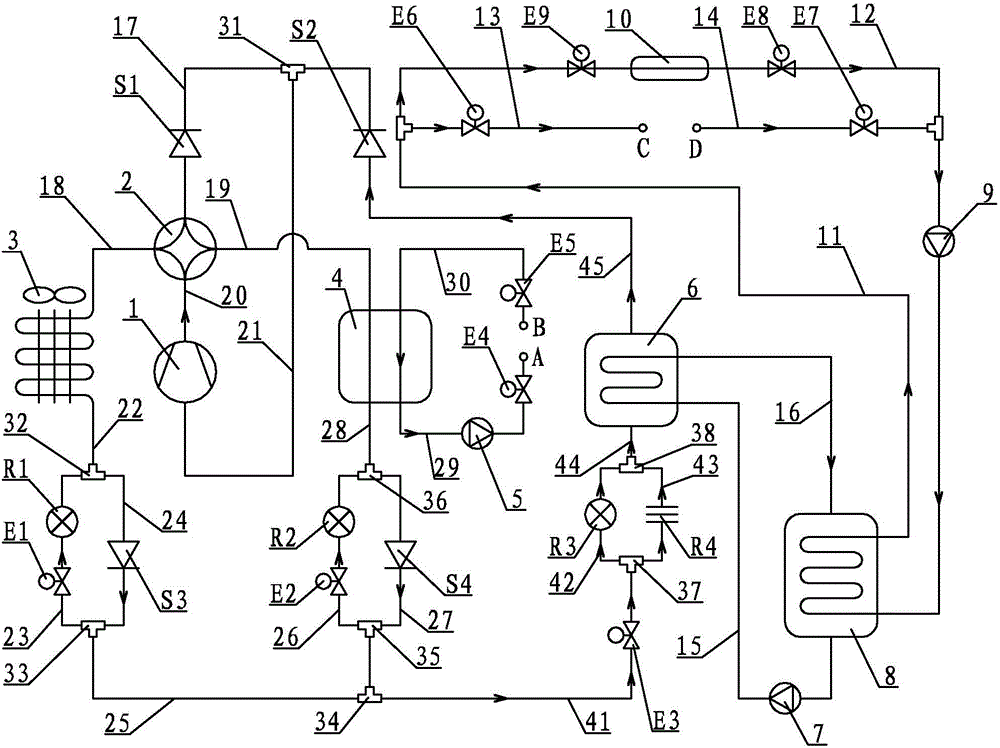

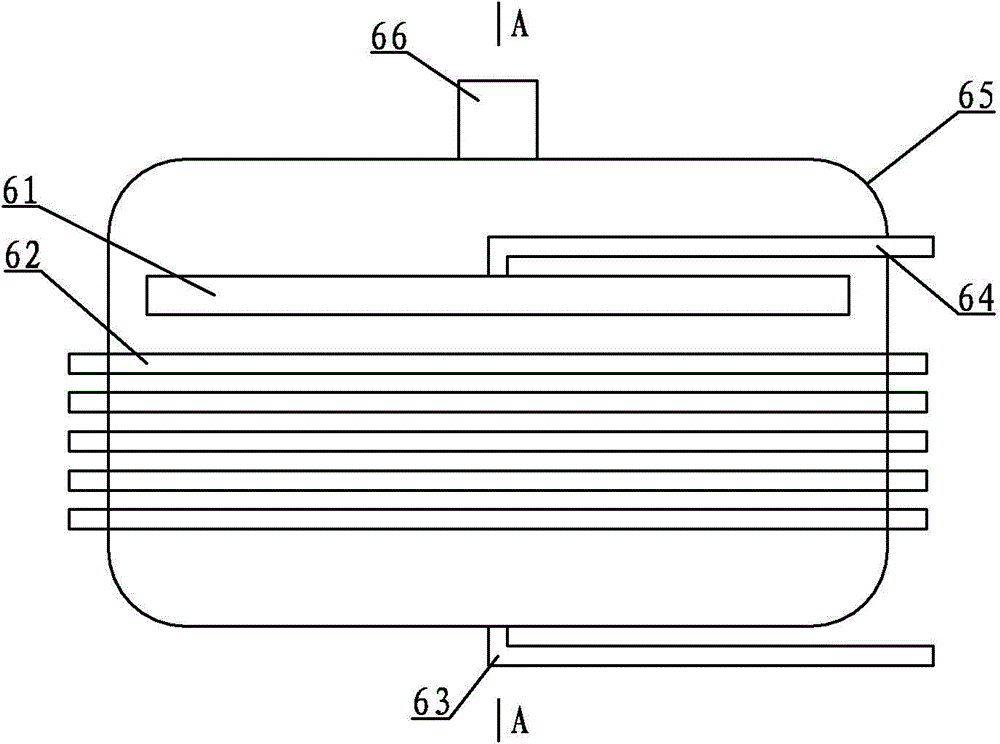

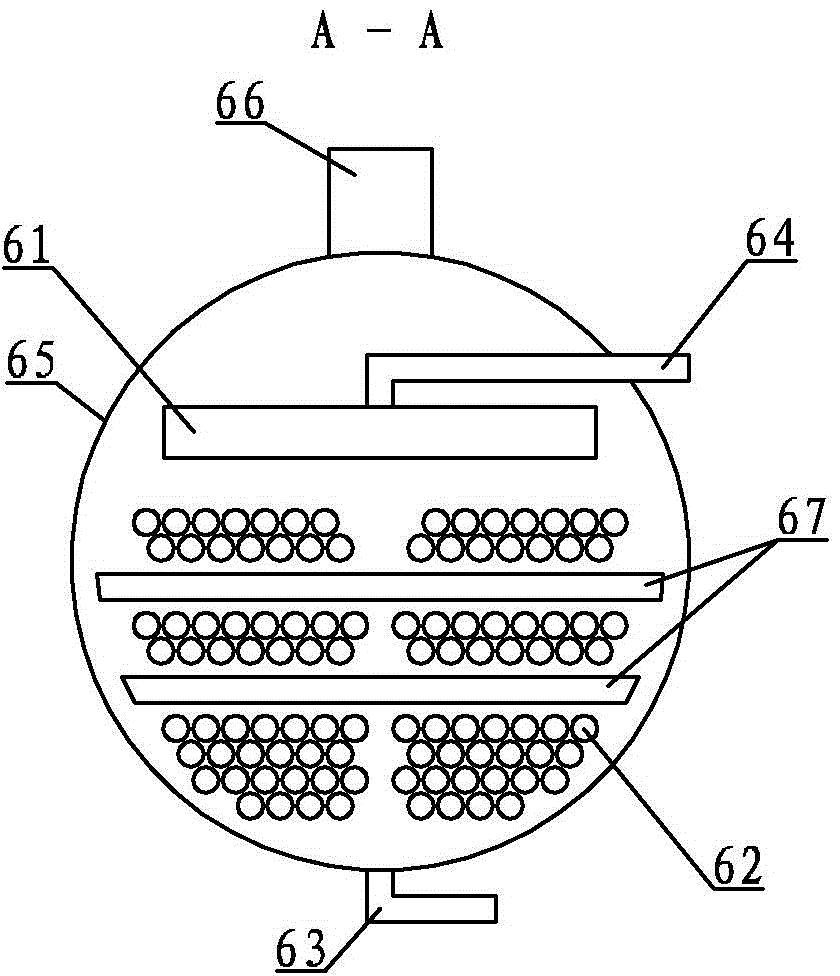

[0022] Specific implementation mode one: combine Figure 1 to Figure 6Describe this embodiment, this embodiment includes a compressor 1, an electric four-way reversing valve 2, an outdoor finned tube air heat exchanger 3, a refrigerant / water dry heat exchanger 4, a hot and cold water circulation pump 5, Falling film energy storage evaporator 6, stainless steel magnetic pump 7, energy storage tank 8, water pump 9, solar heat collector 10, first pipeline 11, second pipeline 12, third pipeline 13, fourth pipeline 14. Fifth pipeline 15, sixth pipeline 16, seventh pipeline 17, eighth pipeline 18, ninth pipeline 19, tenth pipeline 20, eleventh pipeline 21, twelfth pipeline 22. Thirteenth pipeline 23, fourteenth pipeline 24, fifteenth pipeline 25, sixteenth pipeline 26, seventeenth pipeline 27, eighteenth pipeline 28, nineteenth pipeline 29 , the twentieth pipeline 30, the first three-way 31, the second three-way 32, the third three-way 33, the fourth three-way 34, the fifth three-w...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination figure 1 To describe this embodiment, the refrigerant selected for the falling film evaporation energy storage heat pump unit of this embodiment is R134a refrigerant. R134a refrigerant is a medium and low temperature environmentally friendly refrigerant with good overall performance. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0024] Specific implementation mode three: combination Figure 7 and Figure 8 To illustrate this embodiment, the throttling orifice R4 of this embodiment is composed of two orifice R41 connected in series, and each orifice R41 is provided with several throttling holes R411. The existing orifice plate R41 is a single hole structure. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com