Punching press shaped high sealing tropical type plastic aluminium composite hard sheet and production technology

A composite hard sheet and plastic-aluminum technology, which is applied in the direction of layered products, metal layered products, chemical instruments and methods, etc., can solve the problems of undiscovered literature and achievement reports, etc., and achieve the effect of short time period and low ton price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

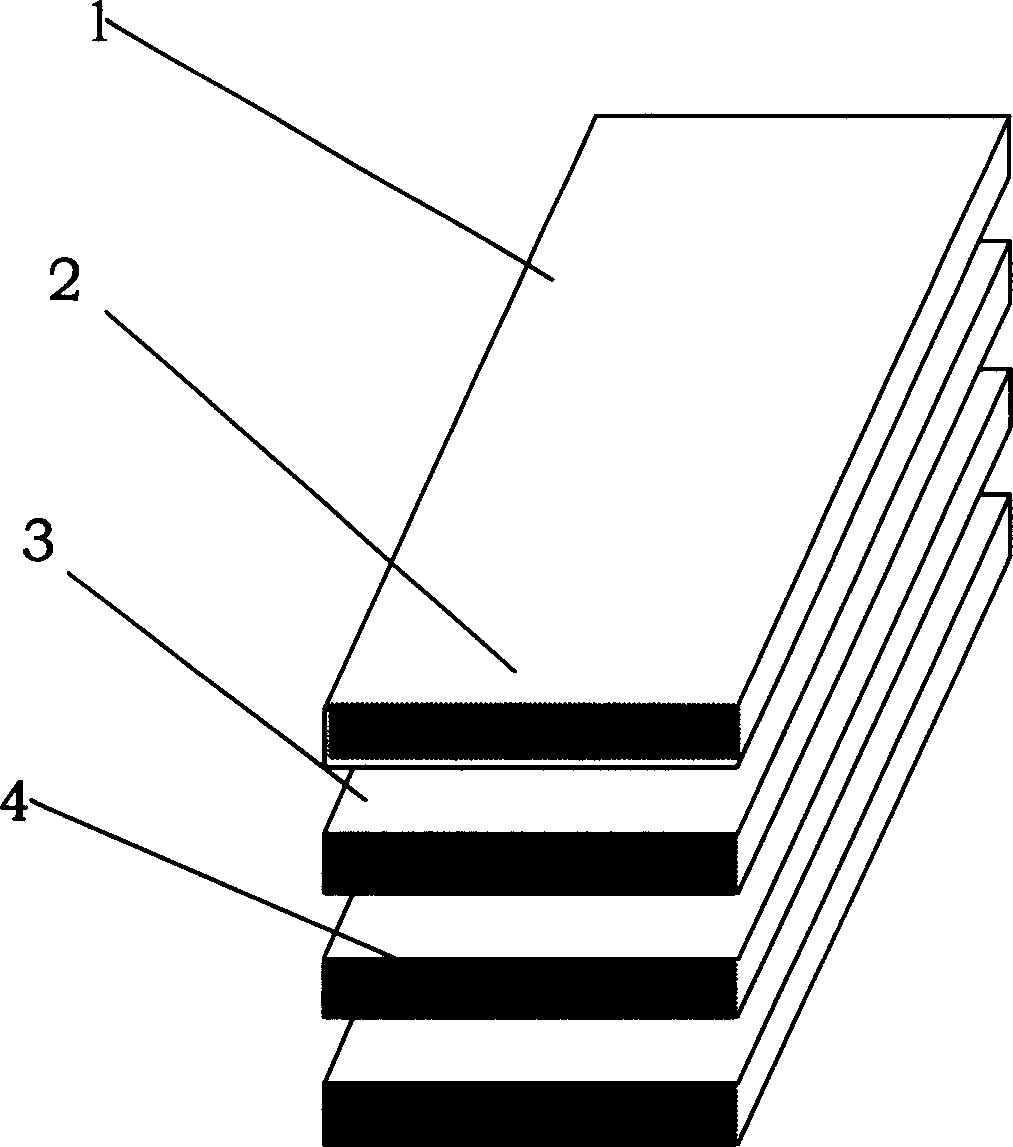

[0033] The figure shows polyester 1 (or polyamide) / aluminum foil 2 / polyester 3 (or polyamide) / aluminum foil 4 formed by a dry laminating machine...even-numbered multi-layer composite plastic aluminum, and finally coated with heat The high-sealing tropical-type plastic-aluminum composite hard sheet composed of sealing glue can be punched and formed, and the thickness reaches about 0.08-0.12mm. Among them, the first base material adopts heat-resistant polyester film with high mechanical strength and rigidity, scratchy surface. The polyester film is a film formed by biaxially stretching polyethylene terephthalate, or a nylon film made of biaxially stretched nylon resin. The thickness of the aluminum foil is selected to be 0.02mm-0.06mm. On the basis of the traditional aluminum-magnesium alloy, silicon is added to form a new reinforced Mg 2 Si aluminum foil, can significantly improve the tensile strength and elongation.

[0034] According to the manufacturing method and technolo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com