Quick-drying non-sticky ultraviolet (UV) ink-jet ink and preparation method thereof

An inkjet ink, quick-drying technology, applied in ink, household utensils, applications, etc., can solve problems such as light is not easy to penetrate, the surface is not dry and sticky, the bottom of the coating is not dry and the adhesion is not good, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

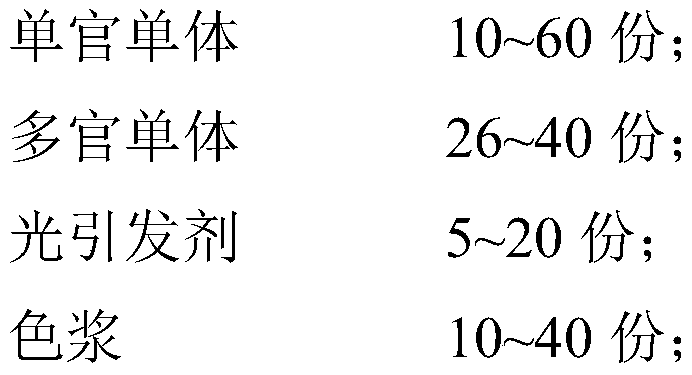

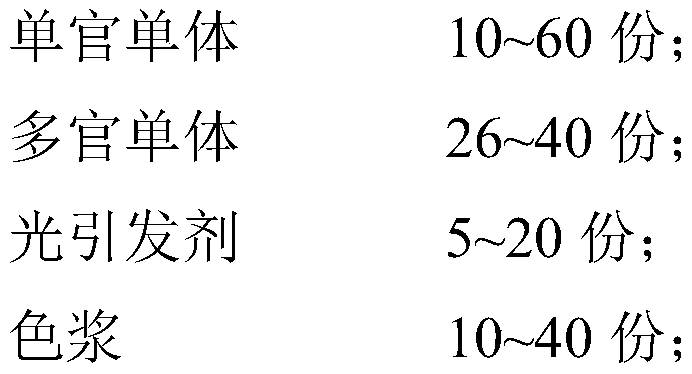

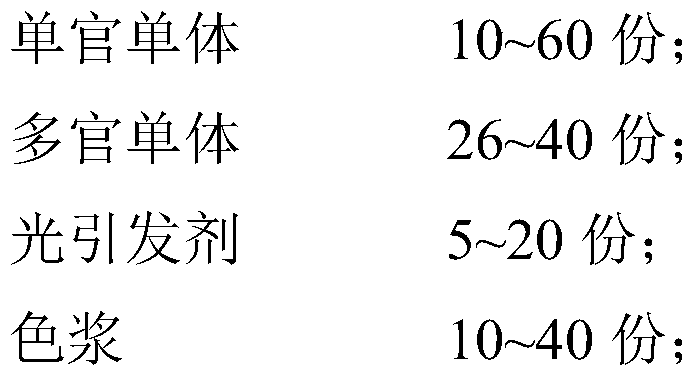

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a preparation method of the quick-drying non-stick UV inkjet ink described in the above technical solution, comprising the following steps:

[0044] (1) Dissolving the photoinitiator by monomer to obtain a pre-solution;

[0045] (2) Stir and mix the color paste with the pre-solution obtained in the step (1), and then filter to obtain a quick-drying non-stick UV inkjet ink.

[0046] The invention adopts the monomer to dissolve the photoinitiator to obtain the pre-solution. In the present invention, the monomers refer to the monofunctional monomers and polyfunctional monomers described in the foregoing technical solutions. In the present invention, there is no particular limitation on the specific implementation of the monomer-dissolving photoinitiator, and a method well known to those skilled in the art can be used.

[0047] After the pre-solution is obtained, the present invention stirs and mixes the color paste and the pre-solution...

Embodiment 1

[0065] The fast-drying non-stick inkjet ink consists of: 24% tetrahydrofurfuryl acrylate, 30% 1,6-hexanediol diacrylate, epoxy acrylate (one functional group in a single oligomer molecule) in parts by mass. Number≧2) 5.0%, polyurethane resin 5.0%, 2,4,6-trimethylbenzoyldiphenylphosphine oxide 8.0%, bis(2,4,6-trimethylbenzoyl)phenyl oxide Phosphine 2.0%, leveling agent BYK-3370.3%, stabilizer GENORAD16 0.7%, phenoxyethyl acrylate 14%, Solsperse240001.0%, white pigment (titanium dioxide) 10%.

[0066] The preparation method of the fast-drying non-stick inkjet ink is as follows: after mixing tetrahydrofurfuryl acrylate, 1,6-hexanediol diacrylate, epoxy acrylate oligomer, polyurethane resin, leveling agent and stabilizer , mixed with 2,4,6-trimethylbenzoyldiphenylphosphine oxide and bis(2,4,6-trimethylbenzoyl)phenylphosphine oxide to obtain a pre-solution;

[0067] Mix the pre-solution with the color paste, and the stirring speed is 1000rpm. The colorants included phenoxyethyl a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com