Modified separation membrane for membrane distillation, and preparation method and application thereof

A separation membrane and membrane distillation technology, which is applied in semipermeable membrane separation, chemical instruments and methods, and membranes, can solve problems such as easy wetting and easy pollution of separation membranes, and achieve high salt cut-off rate, stable permeation flux, The effect of broadening the modification pathway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

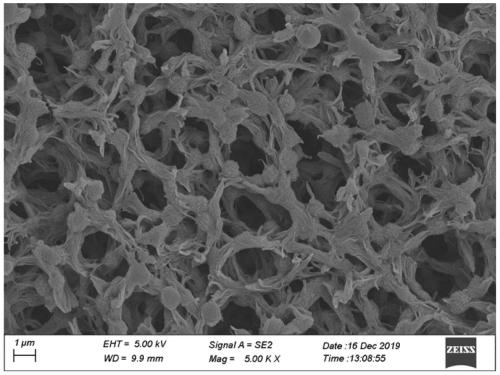

[0047] A modified separation membrane for membrane distillation, the specific modification process is as follows:

[0048] (1) Fix a commercially dry polyvinylidene fluoride diaphragm (0.45 μm) on a metal clamp with a diameter of 14 cm, and perform surface plasma activation on the diaphragm, with a power of 28w and an irradiation time of 10 minutes;

[0049] (2) Dissolve 0.440g of sodium acetate and 0.428g of sodium periodate in 100mL of pure water, and adjust the pH to 5.0, add 0.1g of dopamine and stir for 2 minutes, and use the prepared solution to perform single-phase reaction on the activated polyvinylidene fluoride membrane. For the coating of the hydrophilic layer, the whole system was reacted on a shaker at 30 rpm for 2 hours. And rinse with deionized water for 5 minutes;

[0050] (3) Configure 1% polyethyleneimine (molecular weight: 800Da) solution, adjust pH=5.0, coat the membrane with polycation electrolyte solution, and react the whole system on a shaker at 30 rpm...

Embodiment 2

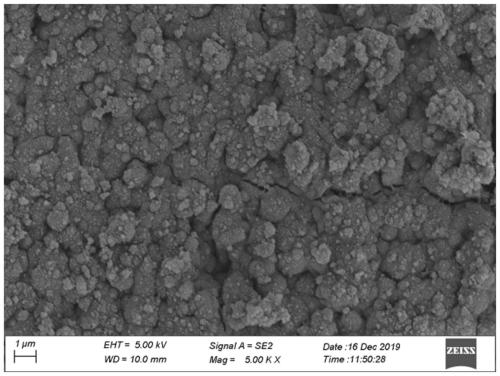

[0054] A modified separation membrane for membrane distillation, the specific modification process is as follows:

[0055] (1) Dissolve 10 g of chitosan powder and 10 mL of glacial acetic acid in 1 L of pure water, and keep stirring until the chitosan is completely dissolved.

[0056] (2) Fix a commercially dry polyvinylidene fluoride diaphragm (0.45 μm) on a metal clamp with a diameter of 14 cm, and perform surface plasma activation on the diaphragm, with a power of 28w and an irradiation time of 10 minutes;

[0057] (3) Dissolve 0.440g sodium acetate, 0.428g sodium periodate, and 40mL chitosan solution in 60mL pure water, and adjust the pH to 5.0, add 0.1g catechol and stir for 2 minutes, and use the prepared solution to The activated polyvinylidene fluoride membrane is coated with a hydrophilic layer on one side, and the whole system is reacted on a shaker at 30 rpm for 2 hours, and rinsed with deionized water for 5 minutes;

[0058] (4) Configure 1% polyethyleneimine (mol...

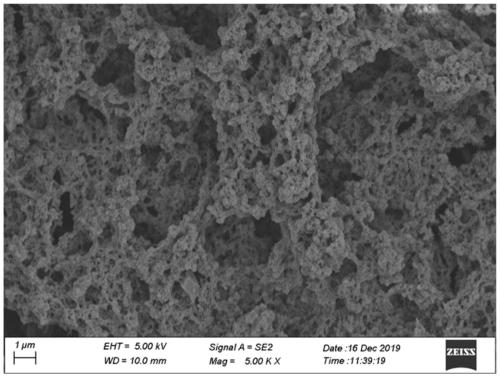

Embodiment 3

[0062] Example 3 adopts the same preparation method as that of Example 2, except that the molecular weight of polyethyleneimine is 750,000Da.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Maximum aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com