Color film substrate and preparation method thereof, and display device

一种彩膜基板、彩膜层的技术,应用在彩膜基板及其制备方法以及显示装置领域,能够解决彩膜基板良率低等问题,达到良率高、易于实现、简化工艺的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

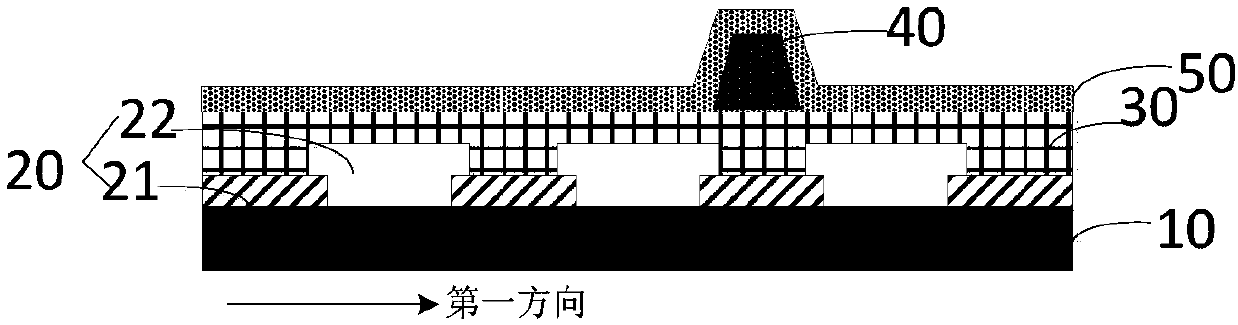

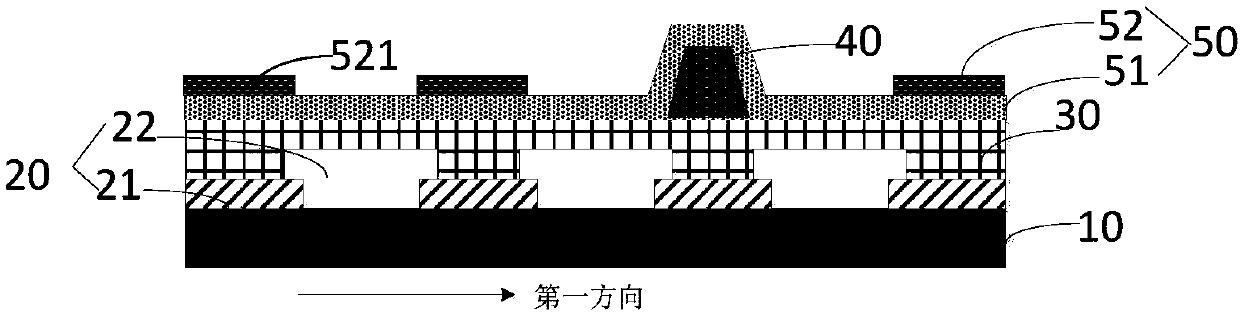

[0068] In this example, refer to Figure 6 to Figure 9 and figure 2 , wherein the electrode 50 includes a transparent conductive oxide electrode 51 and sub-metal electrodes 521 arranged at intervals in the first direction, and the method for preparing the color filter substrate is as follows:

[0069] 1. The glass substrate 10 is cleaned, and the black matrix 21, the color filter 22, and the cover layer 30 are continuously deposited on the substrate 10, wherein the color filters 22 are deposited successively during the preparation of the R, G, and B color filters, And make the color filter 22 have a certain coverage to the black matrix 21;

[0070] 2. Deposit the spacer 40 material and form a pattern, so that the spacer 40 pattern is located directly above the light-shielding metal pattern (or black matrix 21 pattern), and the width of the pattern is slightly smaller than the width of the black matrix 21 pattern;

[0071] 3. Deposit a layer of transparent conductive oxide e...

Embodiment 2

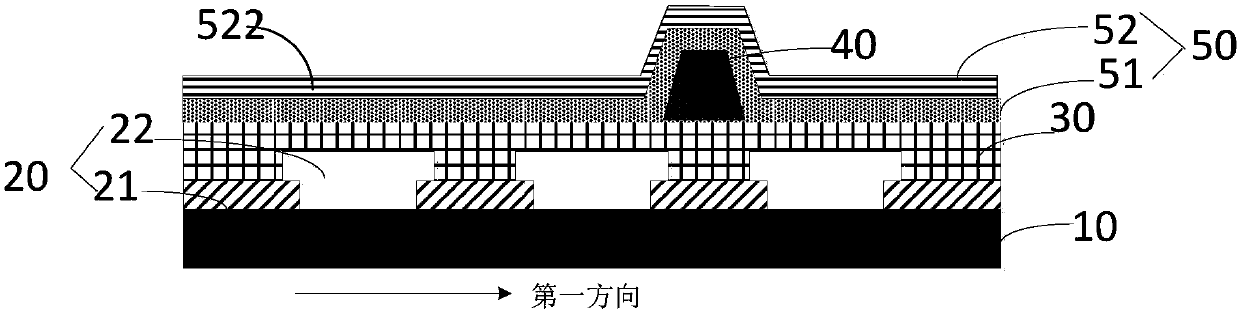

[0074] In this example, refer to Figure 6 to Figure 9 and image 3 , wherein the electrode 50 includes a transparent conductive oxide electrode 51 and a first transparent metal surface electrode 522, and the method for preparing the color filter substrate is as follows:

[0075] 1. The glass substrate 10 is cleaned, and the black matrix 21, the color filter 22, and the covering layer 30 are continuously deposited on the substrate 10, and the color filters of R, G, and B are successively deposited during the preparation of the color filter 22 , and make the color filter 22 cover the black matrix 21 to a certain extent;

[0076] 2. Deposit 40 layers of spacer material and form a pattern, so that the spacer 40 pattern is located directly above the black matrix 21 pattern, and the width of the pattern is slightly smaller than the width of the black matrix 21 pattern;

[0077] 3. Finally deposit a layer of transparent conductive oxide electrode 51 film and a thin layer of transp...

Embodiment 3

[0079] In this example, refer to Figure 6 to Figure 9 and Figure 4 , wherein the electrode 50 includes a second transparent metal surface electrode 523, and the method for preparing the color filter substrate is as follows:

[0080] 1. The glass substrate 10 is cleaned, and the black matrix 21, the color filter 22, and the covering layer 30 are continuously deposited on the substrate, and the color filters of R, G, and B are successively deposited during the preparation of the color filter 22 layers, And make the color filter 22 have a certain coverage to the black matrix 21;

[0081] 2. Deposit 40 layers of spacer material and form a pattern, so that the spacer 40 pattern is located directly above the black matrix 22 pattern, and the width of the pattern is slightly smaller than the width of the black matrix 22 pattern;

[0082] 3. Finally, a thin layer of transparent metal electrode 523 is deposited, and its material can be Ag, Al, Mg, Ca, Sm, etc., or alloys thereof suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com