Two-component odor-removing hollow glass silicone sealing glue

A glass silicon, two-component technology, used in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of poor substrate adhesion, unstable storage, personal hazards, etc. Good capacitance, improved rheology, and increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A two-component deodorizing hollow glass silicone sealant, made by mixing components A and B,

[0034] (1) The group A is:

[0035] 300 parts of room temperature vulcanized silicone rubber;

[0036] Fumed silica: 10 parts;

[0037] 250 parts of 107 silicone rubber;

[0038] 15 parts of simethicone;

[0039] 300 parts of nano active calcium carbonate;

[0040] (2) The group B is divided into:

[0041] 25 parts of simethicone oil;

[0042] 1.2 parts of titanium complex;

[0043] 50 parts of carbon black;

[0044] 2 parts of tetraethyl orthosilicate;

[0045] 2 parts of propyl orthosilicate;

[0046] 2 parts of dibutyltin dilaurate;

[0047] Adhesion promoter 4 parts;

[0048] Described A component: B component=0.9.

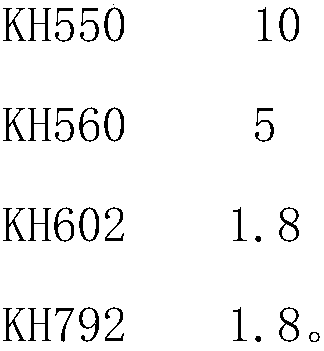

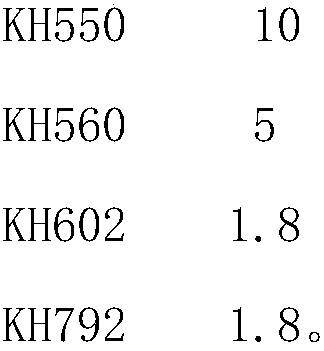

[0049] The adhesion promoter is composed of KH550, KH560, KH602 and KH792, and the four components are mixed and placed for crosslinking. The calculated weight ratio of KH550:KH560 is 2:1, and the weight ratio of KH602:KH792 The ratio is 1:1, the...

Embodiment 2

[0053] A two-component deodorizing hollow glass silicone sealant, made by mixing components A and B,

[0054] (1) The group A is:

[0055] 500 parts of room temperature vulcanized silicone rubber;

[0056] Fumed silica: 15 parts;

[0057] 350 parts of 107 silicone rubber;

[0058] 25 parts of simethicone oil;

[0059] 350 parts of nano active calcium carbonate;

[0060] (2) The group B is divided into:

[0061] 40 parts of simethicone oil;

[0062] 1.6 parts of titanium complex;

[0063] 100 parts of carbon black;

[0064] 5 parts of tetraethyl orthosilicate;

[0065] 5 parts of propyl orthosilicate;

[0066] 5 parts of dibutyltin dilaurate;

[0067] 10 parts of adhesion promoter;

[0068] Described A component: B component=1.1.

[0069] The adhesion promoter is composed of KH550, KH560, KH602 and KH792, and the four components are mixed and placed for crosslinking. The calculated weight ratio of KH550:KH560 is 2:1, and the weight ratio of KH602:KH792 The ratio is...

Embodiment 3

[0074] A two-component deodorizing hollow glass silicone sealant, made by mixing components A and B,

[0075] (1) The group A is:

[0076] 400 parts of room temperature vulcanized silicone rubber;

[0077] Fumed silica: 12 parts;

[0078] 300 parts of 107 silicone rubber;

[0079] 20 parts of simethicone oil;

[0080] 325 parts of nano active calcium carbonate;

[0081] (2) The group B is divided into:

[0082] 30 parts of simethicone oil;

[0083] 1.4 parts of titanium complex;

[0084] 80 parts of carbon black;

[0085] 3 parts of tetraethyl orthosilicate;

[0086] 3 parts of propyl orthosilicate;

[0087] 3 parts of dibutyltin dilaurate;

[0088] 7 parts of adhesion promoter;

[0089] The A component: B component=1.

[0090] The adhesion promoter is composed of KH550, KH560, KH602 and KH792, and the four components are mixed and placed for crosslinking. The calculated weight ratio of KH550:KH560 is 2:1, and the weight ratio of KH602:KH792 The ratio is 1:1, the KH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com