Thermoplastic dynamic vulcanized brominated butyl rubber/polypropylene composition and preparation method thereof

A technology for vulcanizing bromobutyl and polypropylene compositions, applied in the field of composite materials, can solve the problems of high vulcanization activity of bromobutyl rubber, low production and use efficiency, complicated processes, etc. The effect of production efficiency and easy operation of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

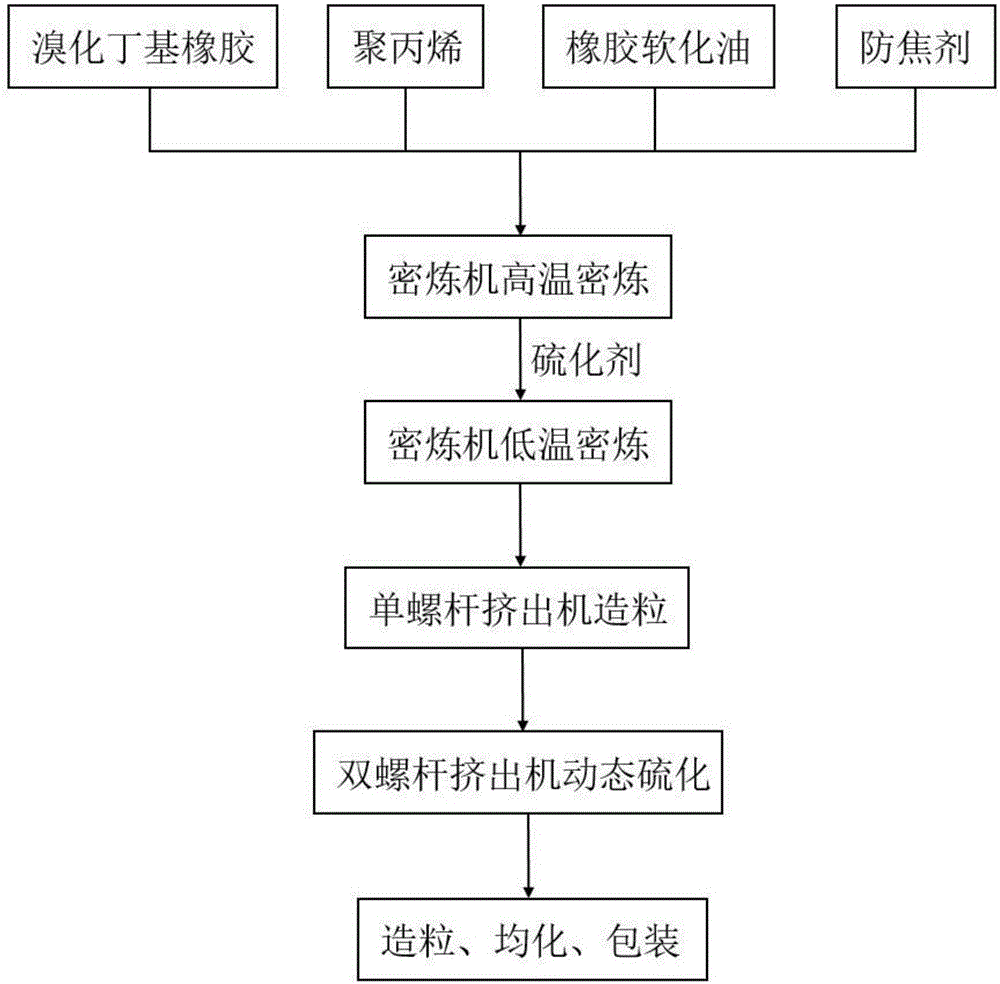

[0052] The preparation method of the above-mentioned thermoplastic dynamic vulcanization bromobutyl rubber / polypropylene composition includes the following steps:

[0053] 1) Add bromobutyl rubber, polypropylene, rubber softening oil, and anti-scorching agent into the internal mixer, and mix well;

[0054] 2) Then add dialkyl peroxide, peroxy acid ester and N,N'-m-phenylene bismaleimide into the internal mixer and mix well;

[0055] 3) Transfer the blend obtained in step 2) to a single screw extruder for granulation;

[0056] 4) The blend obtained in step 3) is transferred to a parallel co-rotating twin-screw extruder for dynamic vulcanization and extrusion granulation to obtain a thermoplastic dynamic vulcanized bromobutyl rubber / polypropylene composition.

[0057] Preferably, the operating temperature of the internal mixer described in step 1) is 160-190°C, the rotor speed of the internal mixer is 70-120 rpm, and the mixing time is 5-20 min.

[0058] Preferably, the operating temperatu...

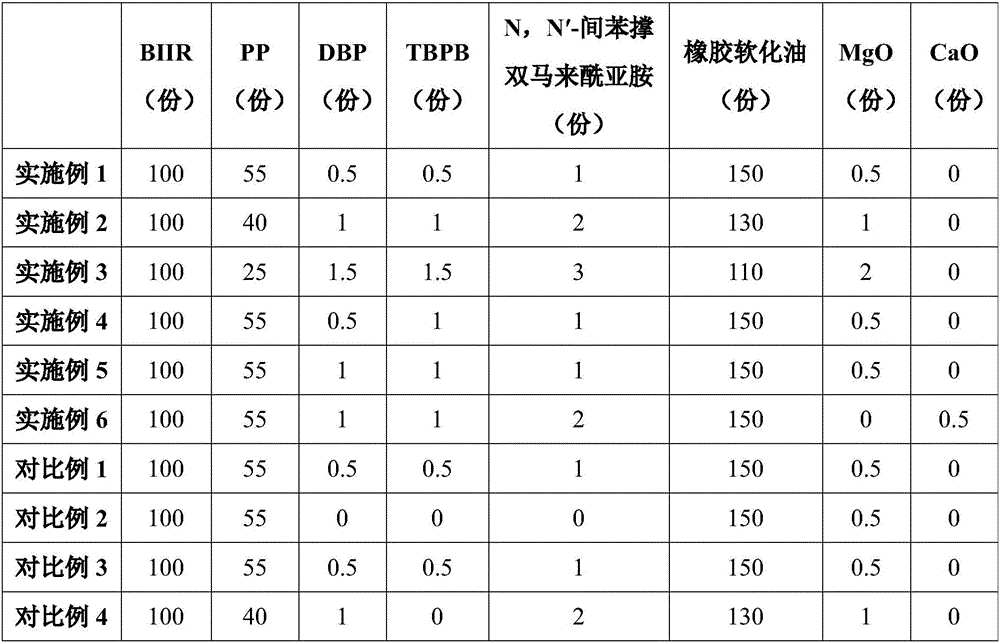

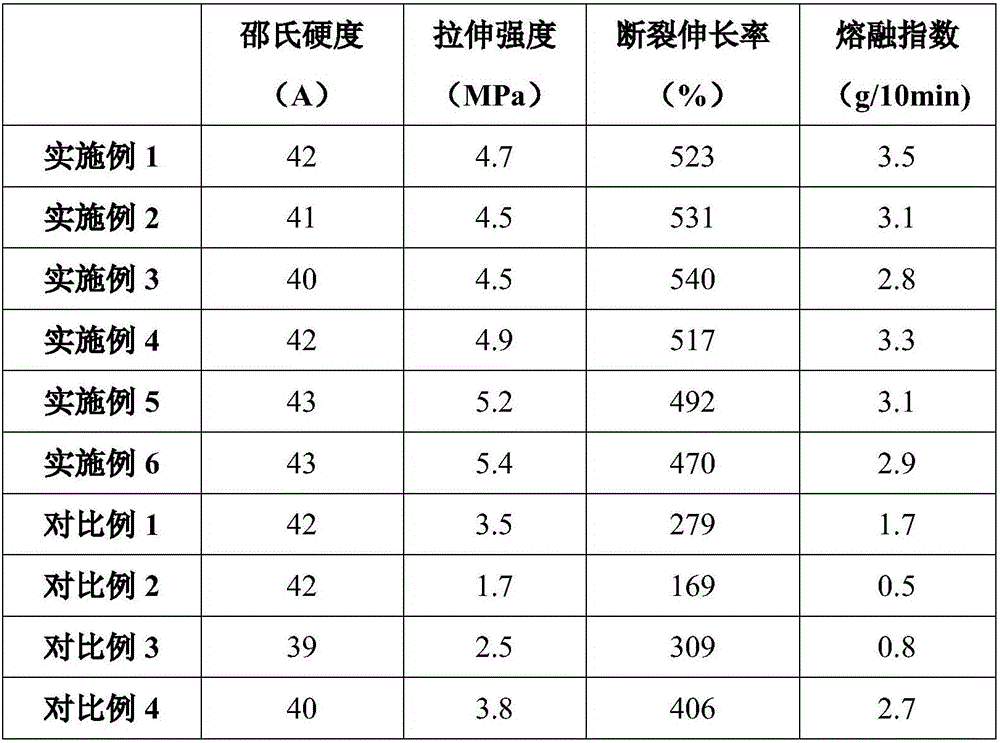

Embodiment 1

[0066] A thermoplastic dynamic vulcanization BIIR / PP composition, the raw material composition of which is as follows (parts by mass):

[0067] BIIR (bromine content 1.8wt%, German LANXESS): 100 copies;

[0068] PP: 55 copies;

[0069] Di-tert-butyl peroxide (Trigonox B): 0.5 parts;

[0070] Tert-butyl peroxybenzoate (Trigonox C): 0.5 parts;

[0071] N,N'-m-phenylene bismaleimide (HVA-2): 1 part;

[0072] Rubber softening oil: 150 parts;

[0073] MgO: 0.5 parts.

[0074] The preparation method of the above-mentioned thermoplastic dynamic vulcanization BIIR / PP composition includes the following steps:

[0075] 1) Put BIIR, PP, rubber softening oil and MgO into the internal mixer, mix evenly, the internal mixer temperature is 190℃, the internal mixer rotor speed is 120rpm, and the internal mixing time is 5min;

[0076] 2) Add DBP, TBPB and HVA-2 to the internal mixer, mix well, the internal mixer temperature is 50℃, the internal mixer rotor speed is 80rpm, and the internal mixing time is 5min;...

Embodiment 2

[0081] A thermoplastic dynamic vulcanization BIIR / PP composition, the raw material composition of which is as follows (parts by mass):

[0082] BIIR (2.0wt% bromine content, Sinopec Yanshan Petrochemical Company): 100 copies;

[0083] PP: 40 copies;

[0084] Di-tert-butyl peroxide (Trigonox B): 1 part;

[0085] Tert-Butyl Peroxybenzoate (Trigonox C): 1 part;

[0086] N,N'-m-phenylene bismaleimide (HVA-2): 2 parts;

[0087] Rubber softening oil: 130 parts;

[0088] MgO: 1 part.

[0089] The preparation method of the above-mentioned thermoplastic dynamic vulcanization BIIR / PP composition includes the following steps:

[0090] 1) Put BIIR, PP, rubber softening oil and MgO into the internal mixer, mix well, the internal mixer temperature is 170℃, the internal mixer rotor speed is 100rpm, and the internal mixing time is 10min;

[0091] 2) Add DBP, TBPB and HVA-2 to the internal mixer, mix well, the internal mixer temperature is 80℃, the internal mixer rotor speed is 60rpm, and the internal mixing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com