Self-extinction waterborne polyurethane resin as well as preparation method and application thereof

A water-based polyurethane, self-extinction technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of small molecular weight, inability to self-extinction, and inability to obtain large molecular chains, so as to improve adhesion and chemical resistance Sex and scratch resistance, easy handling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

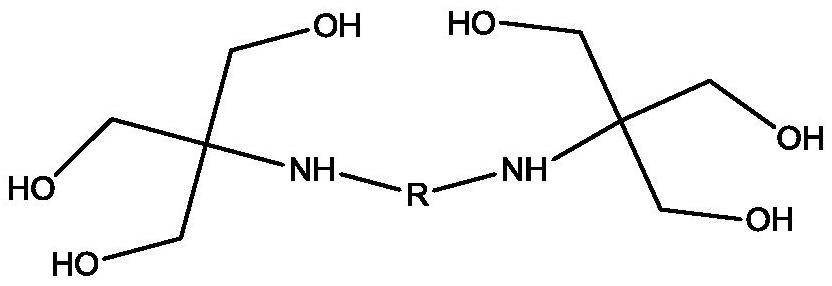

[0097] Preparatory Example 1: Preparation of 1,3-bis((trimethylol)methylamino)propane

[0098] Mix 1,3-dibromopropane and trishydroxymethylaminomethane in an ethanol solvent at a molar ratio of 1:4, react under reflux for 8 hours, cryogenically crystallize at -5°C after the reaction, filter and take the filtrate to acidify with HBr To pH 2, cryogenically crystallize at -5°C and then filter with suction, take the filter cake and dissolve it in absolute ethanol, and adjust the pH to 10 with sodium hydroxide solution, then crystallize in cryogenically at -5°C, filter with suction, and dry to obtain the product Crude. The crude product was first dissolved in hot absolute ethanol, cooled naturally for 30 minutes, vacuum filtered to remove insoluble matter, then recrystallized at room temperature, and filtered to obtain the pure product.

[0099] NMR characterization is as follows:

[0100] 1 H NMR (CDCl 3 ,400MHz,TMS):δ1.58(m,2H),2.55(t,4H),3.38(m,12H).

Embodiment 2

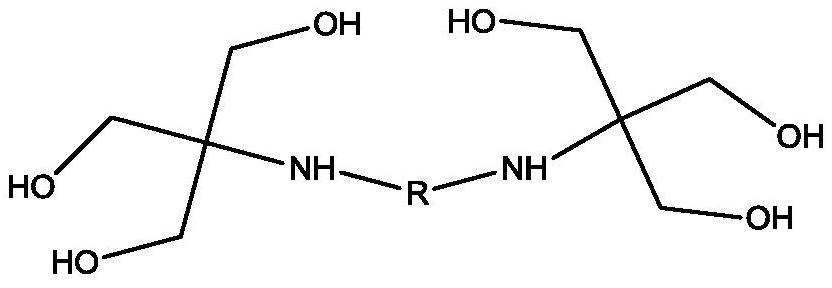

[0101] Preparatory Example 2: Preparation of 1,4-bis((trimethylol)methylamino)butane

[0102] Prepare 1,4-bis((trimethylol)methylamino)butane according to the above method, the only difference is that the raw material 1,3-dibromopropane is replaced by 1,4-dibromobutane.

[0103] NMR characterization is as follows:

[0104] 1 H NMR (CDCl 3 ,400MHz,TMS):δ1.4(m,4H),2.45(m,4H),3.48(m,12H).

Embodiment 3

[0105] Preparatory Example 3: Preparation of 1,5-bis((trimethylol)methylamino)pentane

[0106] Prepare 1,5-bis((trimethylol)methylamino)pentane according to the above method, the only difference is that the raw material 1,3-dibromopropane is replaced by 1,5-dibromopentane.

[0107] NMR characterization is as follows:

[0108] 1 H NMR (CDCl 3 ,400MHz,TMS):δ1.19(m,2H),1.48(m,4H),2.55(t,4H),3.48(m,12H).

[0109] Example 1

[0110]Add 120 g of polycaprolactone diol, 2 g of polyethylene glycol monomethyl ether, 3 g of dimethylolpropionic acid, and 17.5 g of 1,4-cyclohexanedimethanol into a Add 72 grams of IPDI, 0.08 grams of Bi@8108, and 50 grams of acetone to a four-necked flask, react at 70°C for 3 hours, the NCO value is 1.8%, and the theoretical value is 1.89%; cool down to 40°C, add 300 grams of acetone, then add 1.9 grams of dimethylethanolamine, react for 10 minutes at 35 degrees, then add 9 grams of 1,3-bis ((trimethylol) methylamino) propane and 36 grams of deionized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com