Construction method for digging composite environmental protection base of anchorage bar adding rock

A technology of rock bolts and construction methods, which is applied in basic structure engineering, construction and other directions, can solve the problems of increased excavation, insufficient clay layer thickness, manual excavation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

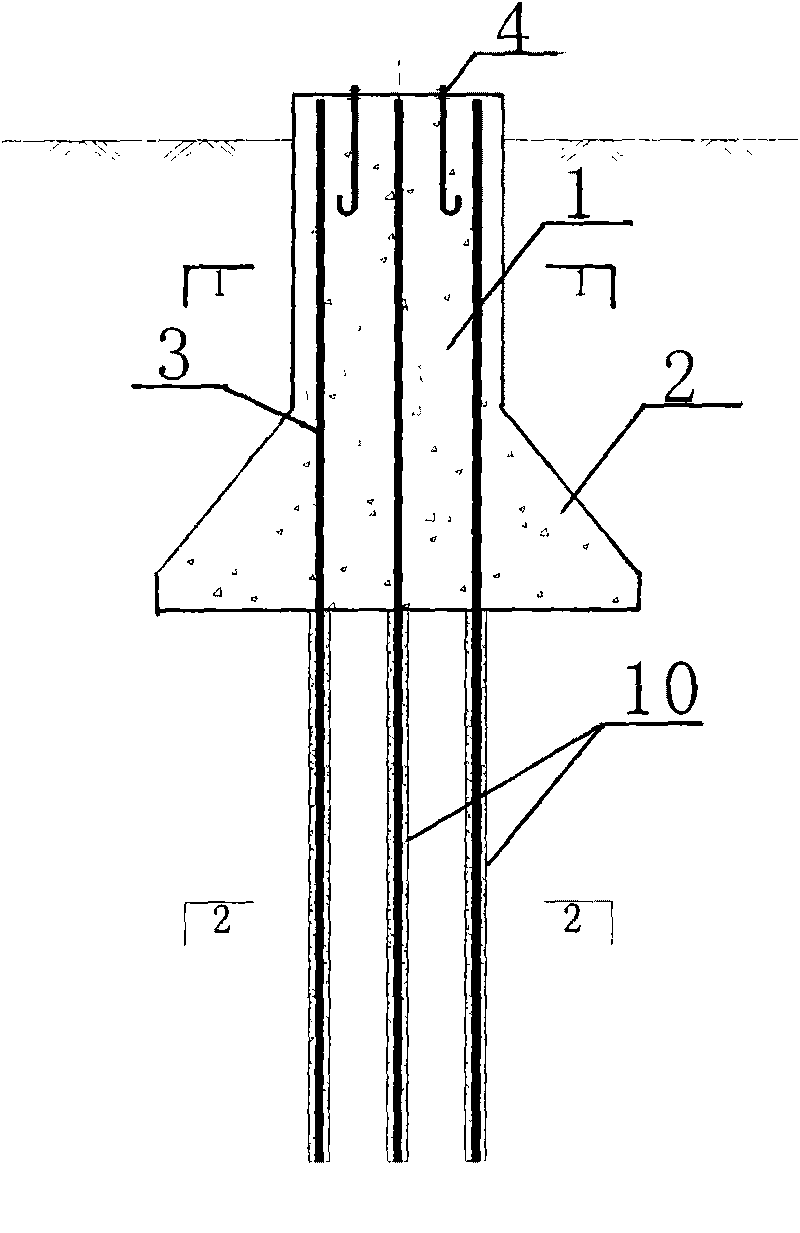

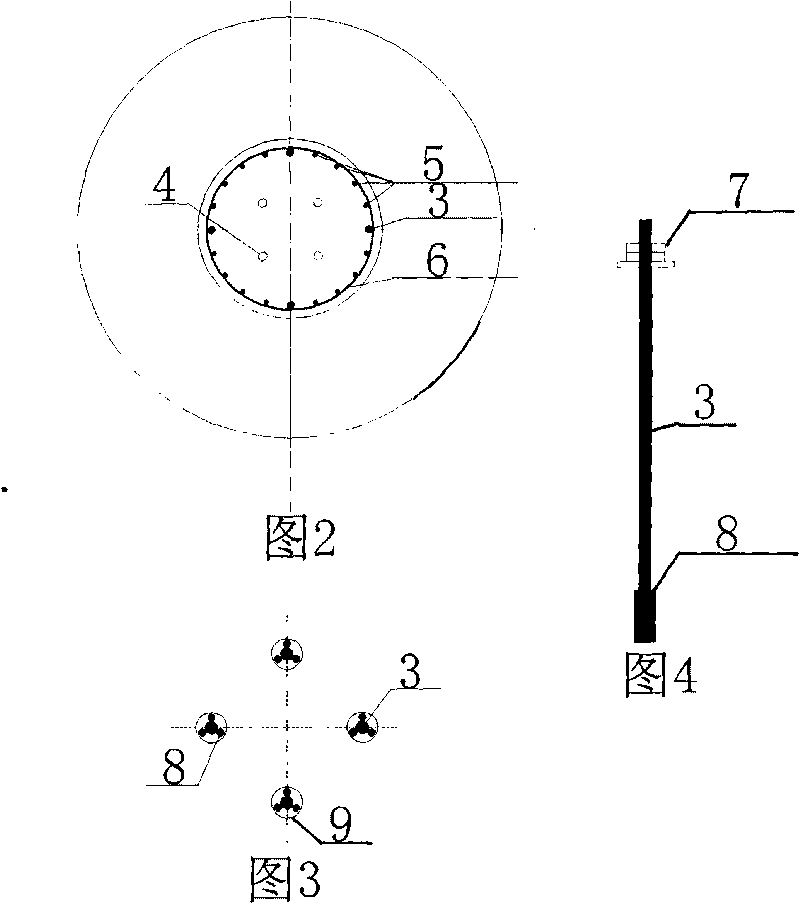

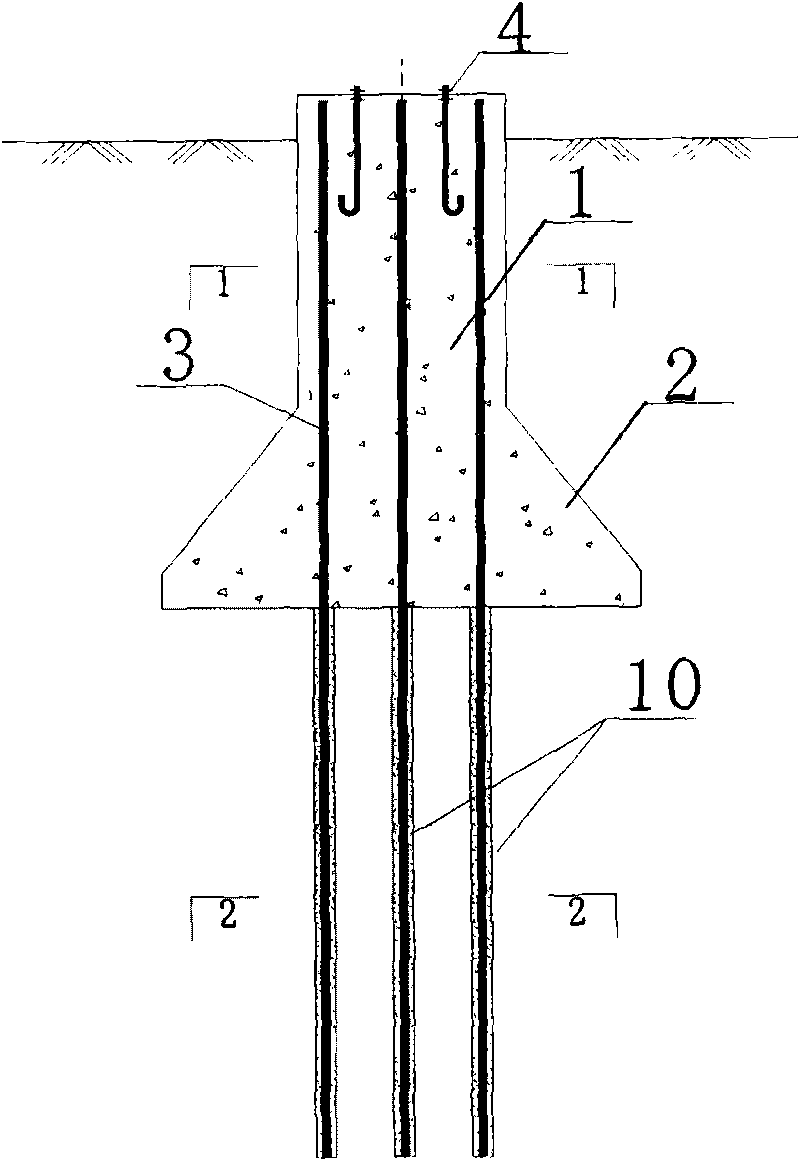

[0033] Reference figure 1 , figure 2 , image 3 , Figure 4 , The present invention includes the following steps:

[0034] (1) First use machinery to drill holes 9 on the ground, and after reaching the design depth, insert anchor bars 3, and weld short bars 8 on both sides of the lower ends of the anchor bars;

[0035] (2) Grouting the space around the anchor bar to form the anchor rod 10, if necessary, pressure grouting, the material of the grouting is C25 fine stone concrete or M15 mortar;

[0036] (3) When the concrete slurry has solidified and hardened to 30% of the design strength, start to manually dig the foundation pit soil and reach the design depth;

[0037] (4) After the foundation pit is formed, cut off the hardened concrete around the anchor bar above the bottom of the pit;

[0038] (5) Put the main column reinforcement cage composed of the main reinforcement 5 and the stirrup 6 into the foundation main column reinforcement cage, and tie or weld the anchor reinforcement an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com