General type assembly welding and positioning device used for various side wall frameworks

A positioning device and general-purpose technology, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems that the welding device of the side wall frame is not universal, time-consuming and labor-intensive to disassemble and install, and low production efficiency, etc., to achieve The effect of improving equipment utilization, reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

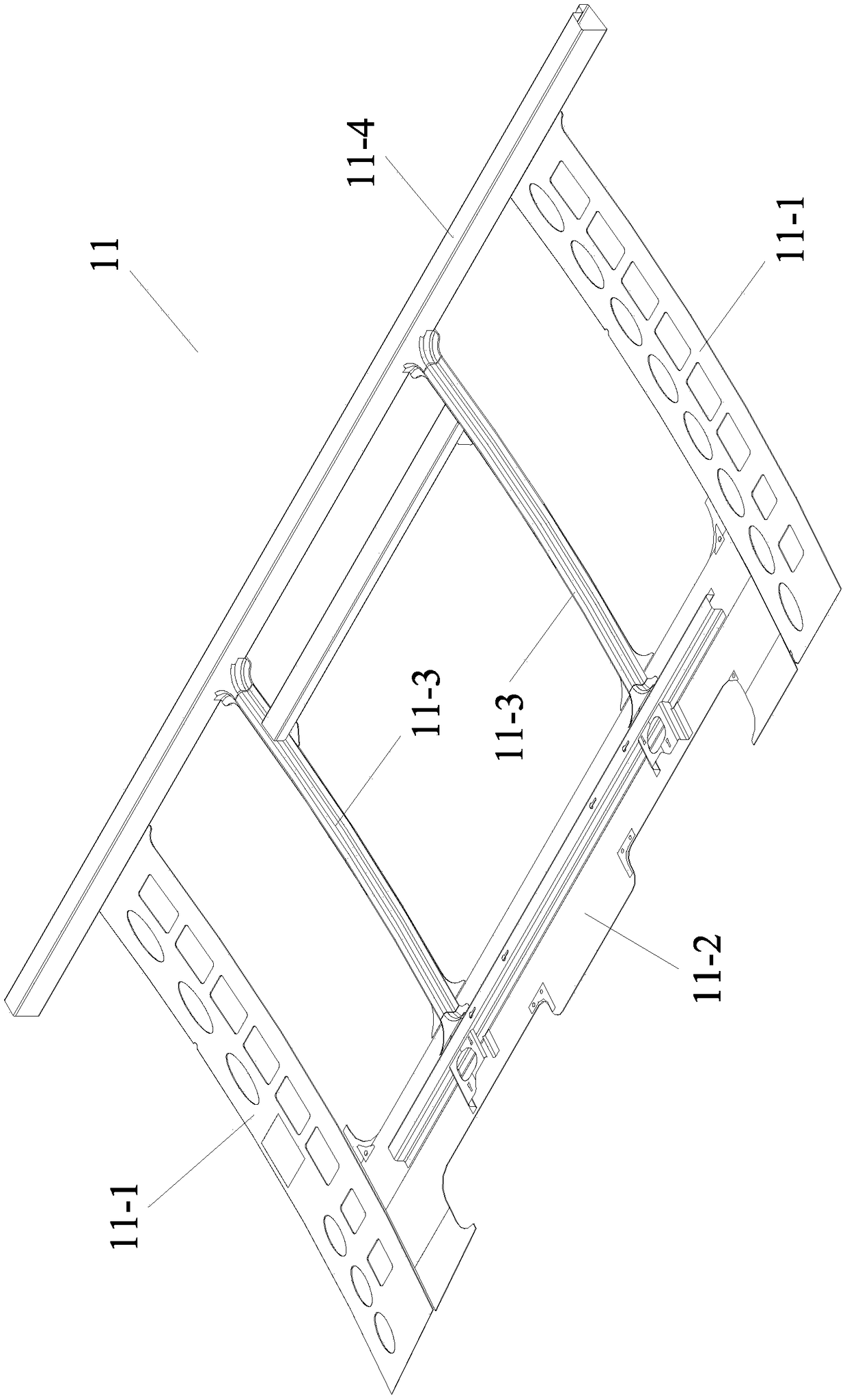

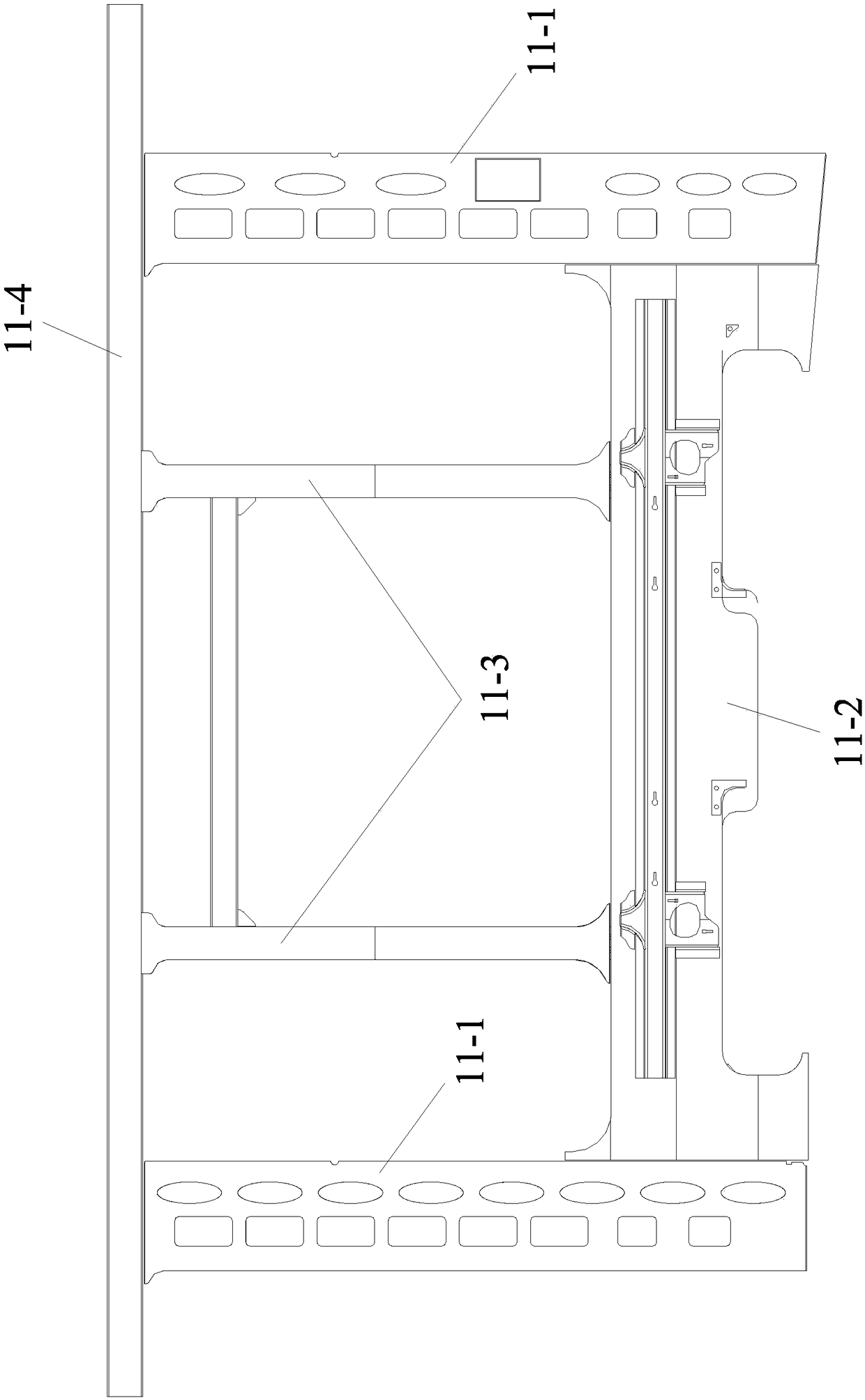

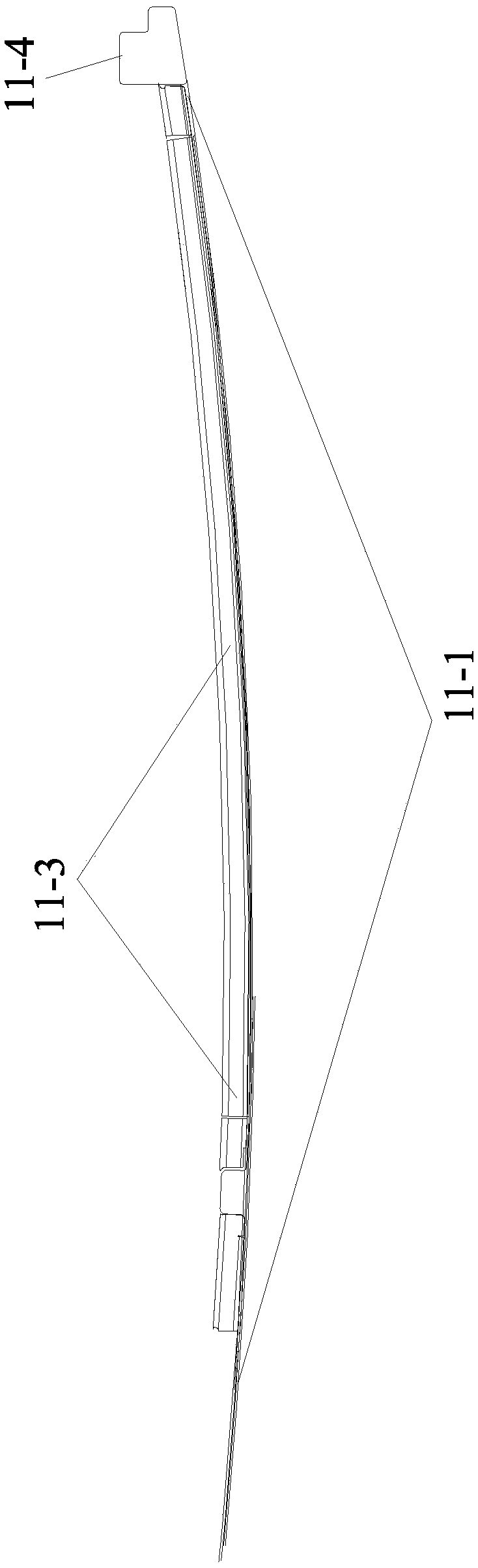

[0024] Such as Figure 4 to Figure 9 As shown, the general-purpose assembly welding positioning device for various side wall frameworks of the present invention includes: multiple base T-shaped groove guide rails 1, multiple height-adjustable bases 2, table tops 3, four pressing mechanisms 4, A plurality of ball head mechanisms 5 , a plurality of pivots 6 , four upper positioning blocks 7 , two lower positioning blocks 8 , a plurality of spacers 9 and two three-sided right-angled positioning blocks 10 . The T-shaped bolt can slide in the T-shaped groove guide rail, and can be locked and positioned at the required fixed position by the nut.

[0025] A plurality of base T-slot guide rails 1 are fixed on the ground in parallel, the bottoms of multiple height-adjustable bases 2 are fixedly connected to the base T-slot guide rails 1 through T-shaped bolts, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com