Retracement method for fan section of fully-mechanized coal mining retracement working face

A fan-shaped area and working face technology, applied in mining equipment, earth-moving mining, mine roof support, etc., can solve the problems of poor safety, high roof pressure in fan-shaped area, and roof subsidence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

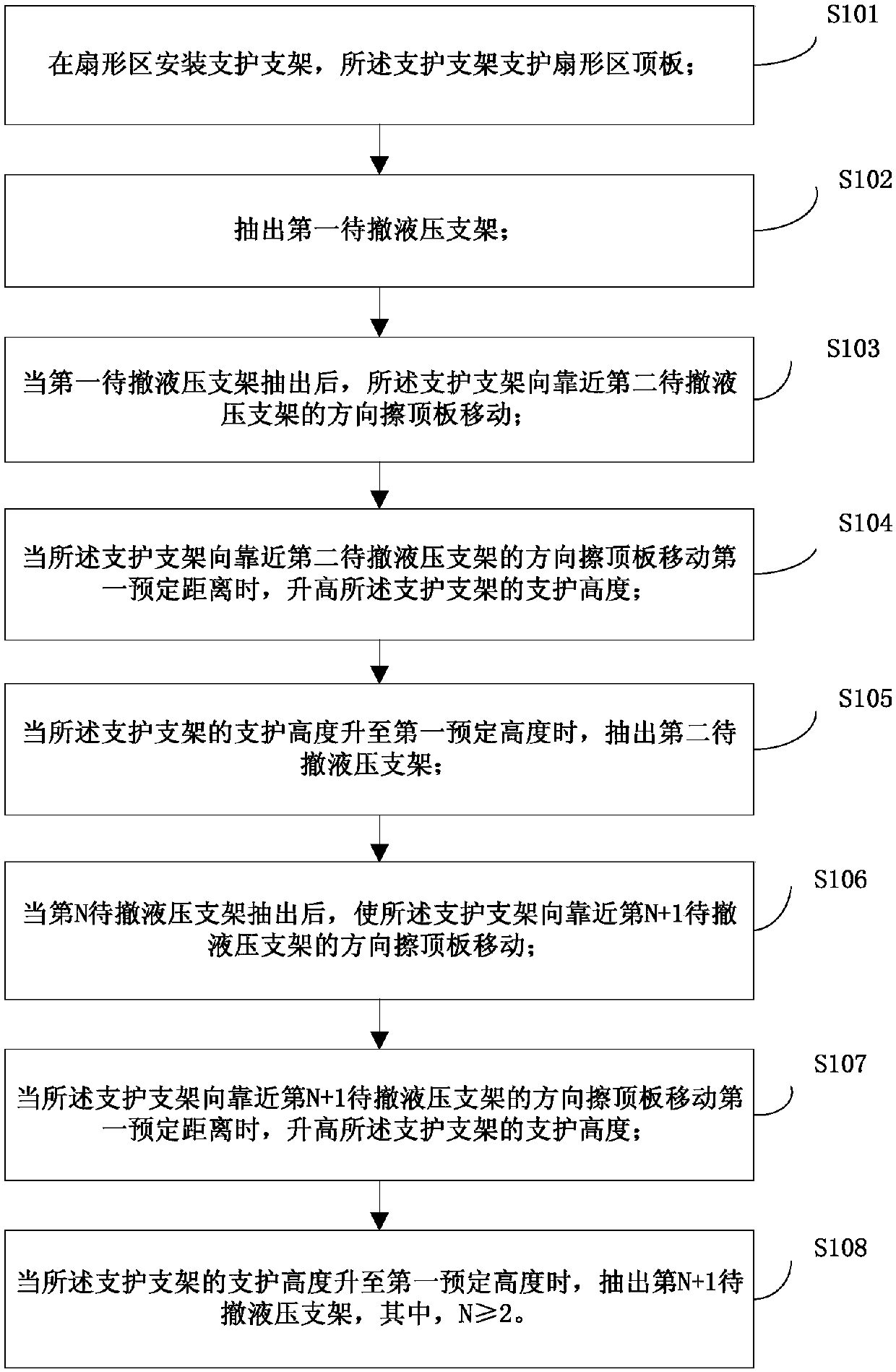

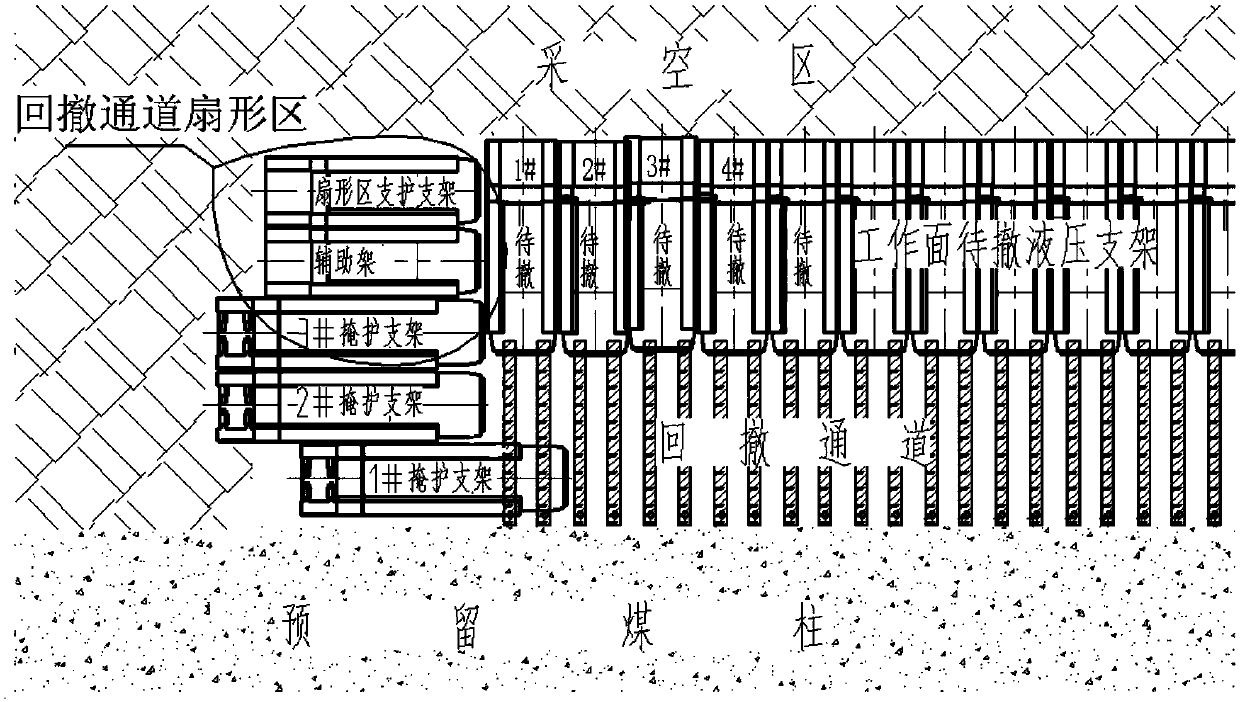

[0025] figure 1 It shows the flow chart of the method for retracting the fan-shaped area of the fully-mechanized mining retraction working face according to the embodiment of the present invention, figure 2 It shows the support layout of the fan-shaped area of the fully-mechanized mining retraction working face according to the embodiment of the present invention, which includes:

[0026] S101, installing a supporting bracket in the fan-shaped area, and the supporting bracket supports the top plate of the fan-shaped area;

[0027] The number of supporting brackets can be set according to the supporting area of the sector roof. The supporting bracket supports the roof of the fan-shaped area, and the supporting force of the supporting bracket on the roof before moving is the initial supporting force of the supporting bracket.

[0028] S102, pulling out the first hydraulic support to be withdrawn;

[0029] All the hydraulic supports to be withdrawn are arranged in paral...

Embodiment 2

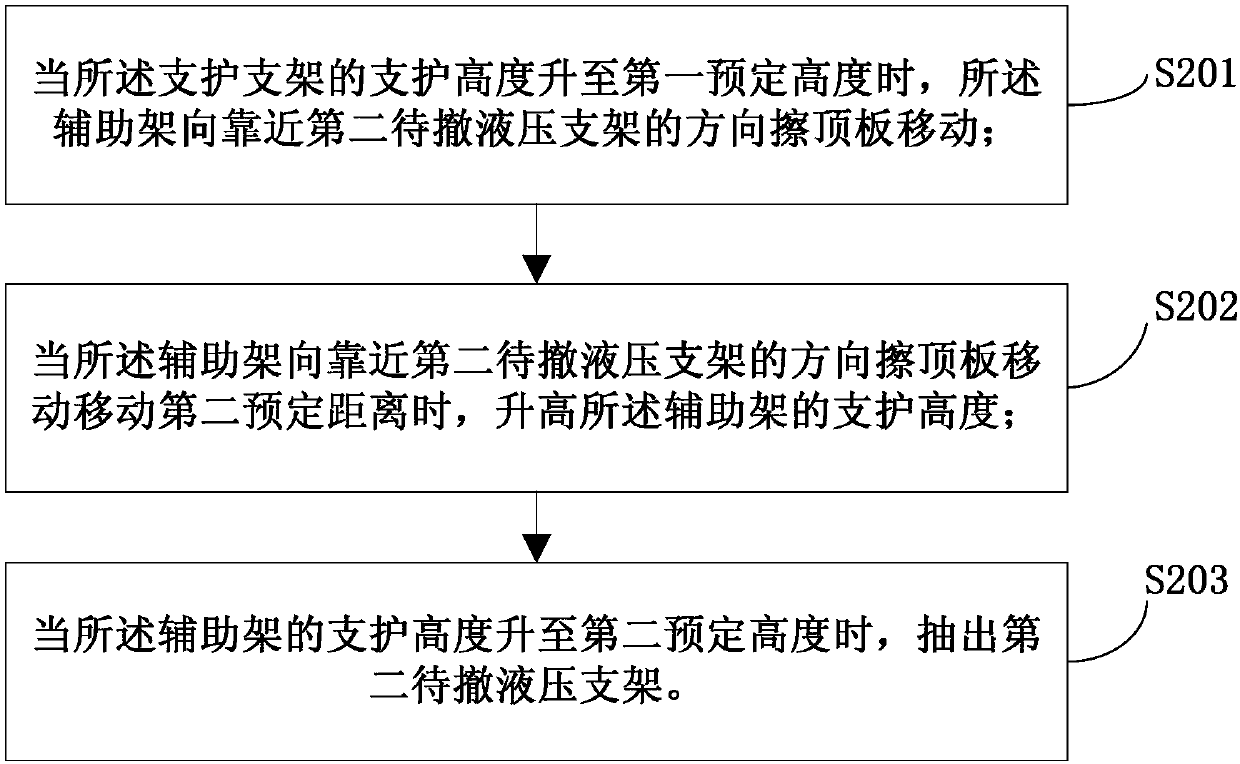

[0042] On the basis of Embodiment 1, the embodiment of the present invention is improved, optionally, as image 3 As shown, the S105 includes:

[0043]S201, when the support height of the support bracket rises to a first predetermined height, the auxiliary frame moves toward the top plate in a direction close to the second hydraulic support to be withdrawn;

[0044] Among them, the auxiliary frame is set adjacent to the support bracket, such as figure 2 As shown, the auxiliary frames are arranged side by side on the side of the support bracket close to the withdrawal channel. The auxiliary frame supports the roof of the fan-shaped area with the auxiliary support bracket. The supporting force on the roof before the auxiliary frame moves is the initial supporting force of the auxiliary frame.

[0045] S202. When the auxiliary frame moves toward the roof in a direction close to the second hydraulic support to be withdrawn and moves a second predetermined distance, raise the s...

Embodiment 3

[0059] On the basis of the second embodiment, the embodiment of the present invention is improved, optionally, as Figure 5 As shown, S203 includes:

[0060] S301, when the support height of the auxiliary frame rises to a second predetermined height, the cover support moves toward the top plate in a direction close to the second hydraulic support to be withdrawn;

[0061] Wherein, the shield bracket is arranged adjacent to the auxiliary frame, and the auxiliary frame is located between the shield bracket and the support bracket, such as figure 2 shown. Shield brackets are also used to support the roof of the sector. The cover support can adopt hydraulic support. The supporting force of the shielding bracket on the top plate before moving is the initial supporting force of the shielding bracket.

[0062] S302. When the shield bracket moves a third predetermined distance to the top plate in a direction close to the second hydraulic support to be withdrawn, raise the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com