Gob-side entry retaining method for pouring spacing concrete walls in tunnel of advanced highwall

A technology for concrete walls and working faces, which is applied to mining equipment, earthwork drilling, shaft lining, etc. It can solve problems such as large roof sinking, heavy workload impact, and gas overrun, and achieve safe and reliable support, reduce The effect of high workload and support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

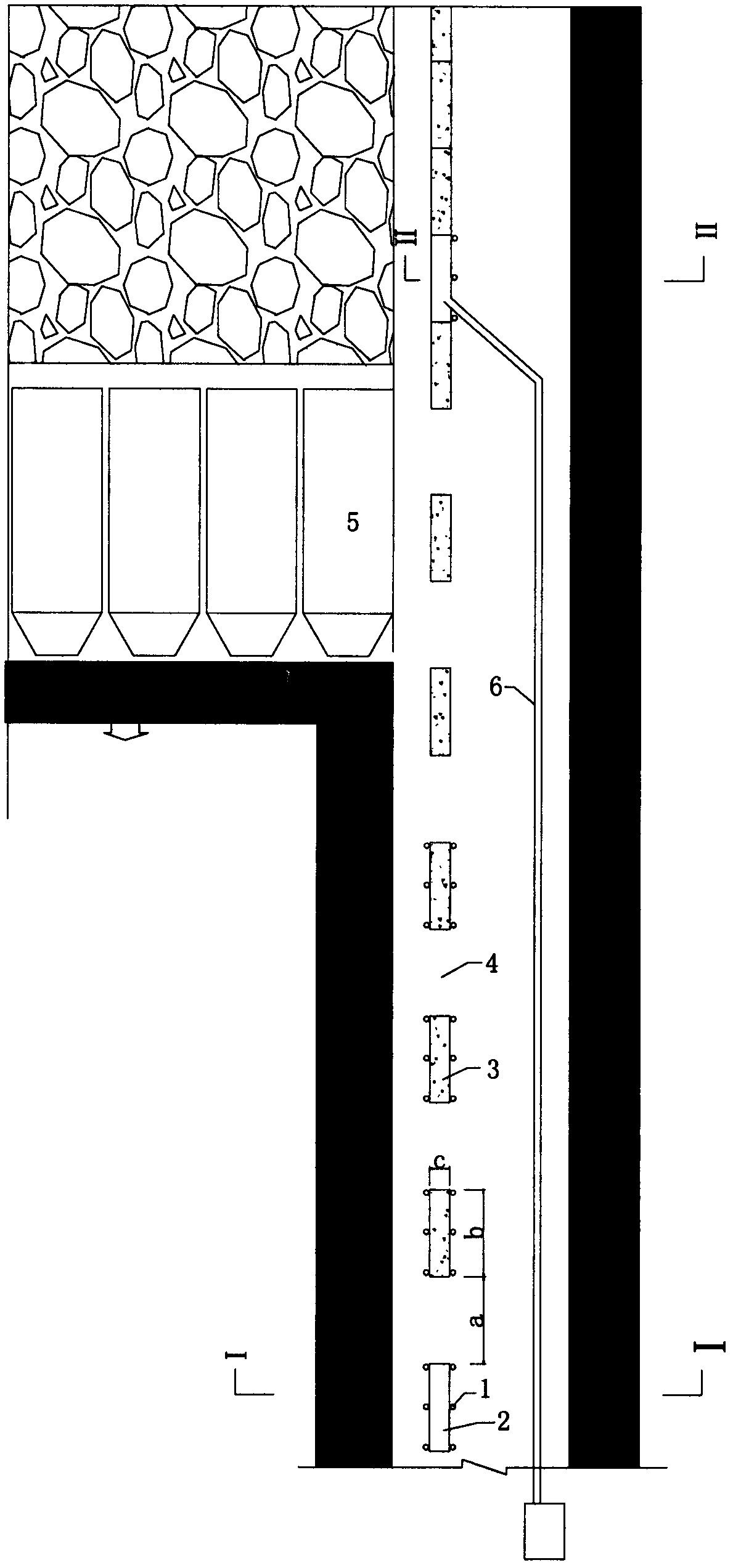

[0019] Below in conjunction with accompanying drawing, content of the invention is further described:

[0020] refer to Figure 1-Figure 3 Shown:

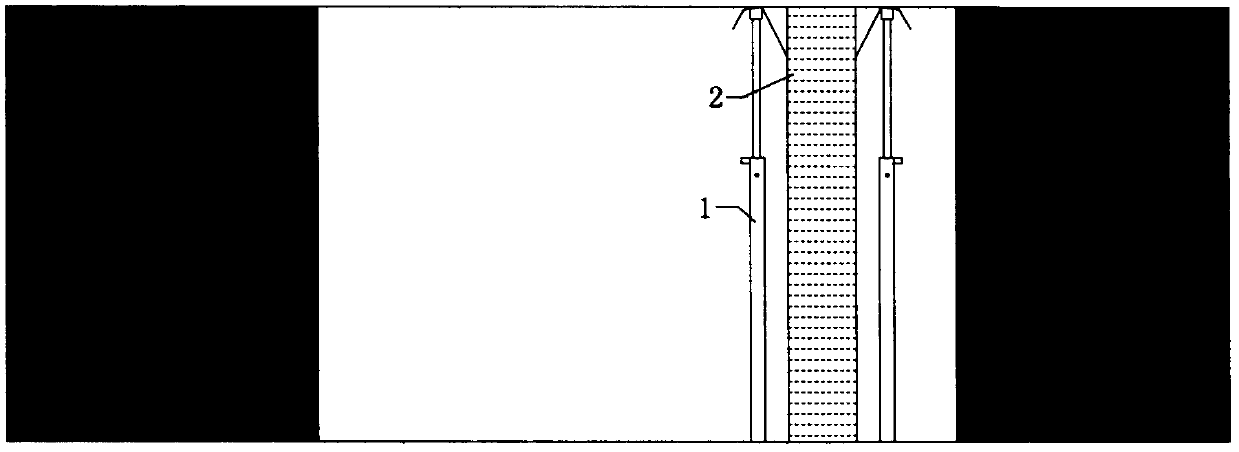

[0021] a. The advanced coal mining face is in the return air trough, and the flexible formwork 2 arranged at three to six intervals is suspended by the single pillar 1. The length b of the flexible formwork 2 is 1-3m, the width c is 0.2-2m, and the height The height of the roadway is the same, and the distance a between the flexible templates 2 is 1-6m.

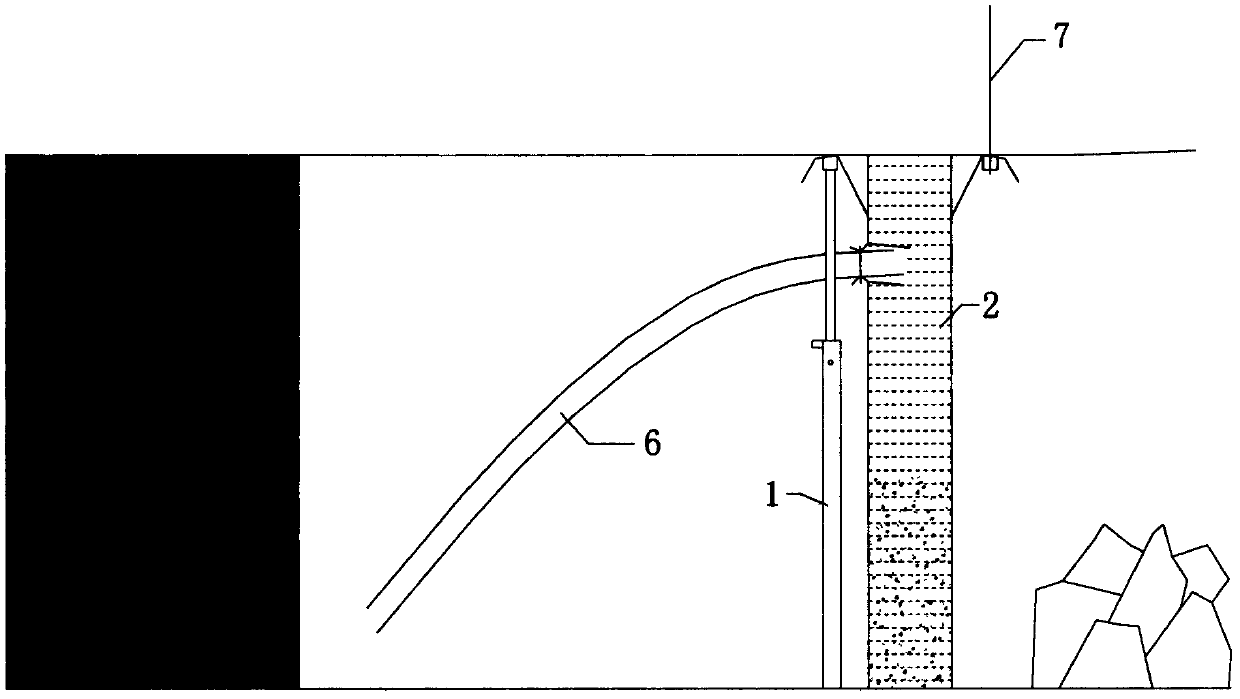

[0022] b. Fill concrete into three to six flexible formworks 2 sequentially through the concrete delivery pipe 6;

[0023] c. After the concrete is hardened, the single pillar 1 used to hang the flexible formwork 2 is removed, and a spaced concrete discontinuous wall 3 is formed in the return air channel of the advanced working face;

[0024] d. Advancing the coal mining face;

[0025] e. The lagging coal mining face is in the reserved roadway along the gob, and one to six fle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com