Accessible circular knitting machine with improved spinning head

A circular knitting machine, knitting machine technology, applied in the direction of circular knitting, knitting, weft knitting, etc. with individual action needles, can solve the problems of occupying space and hindering the operator from accessing the textile head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

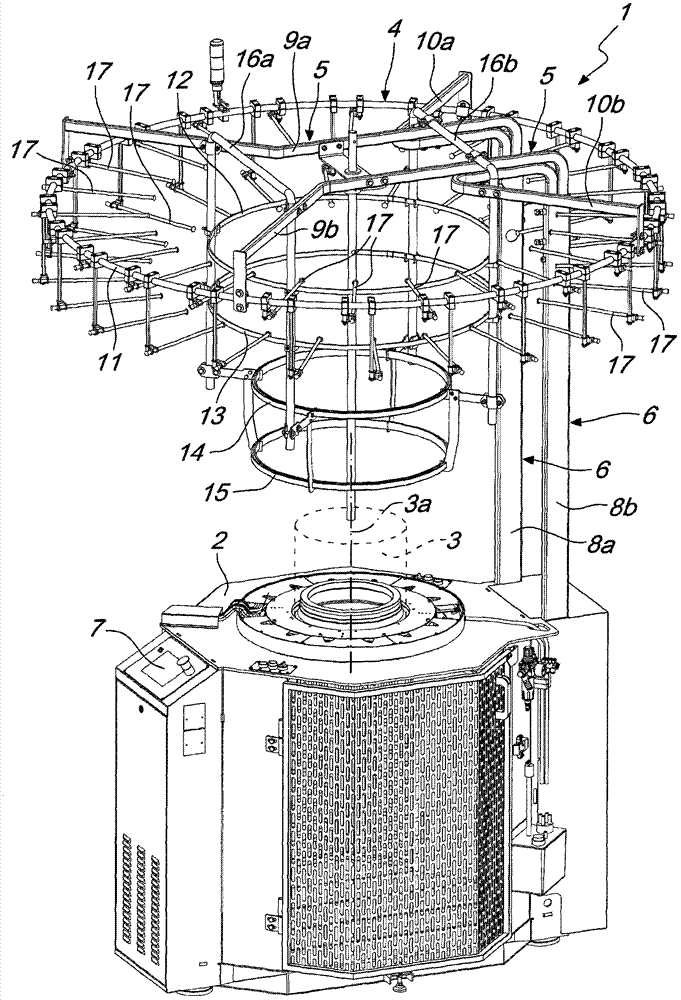

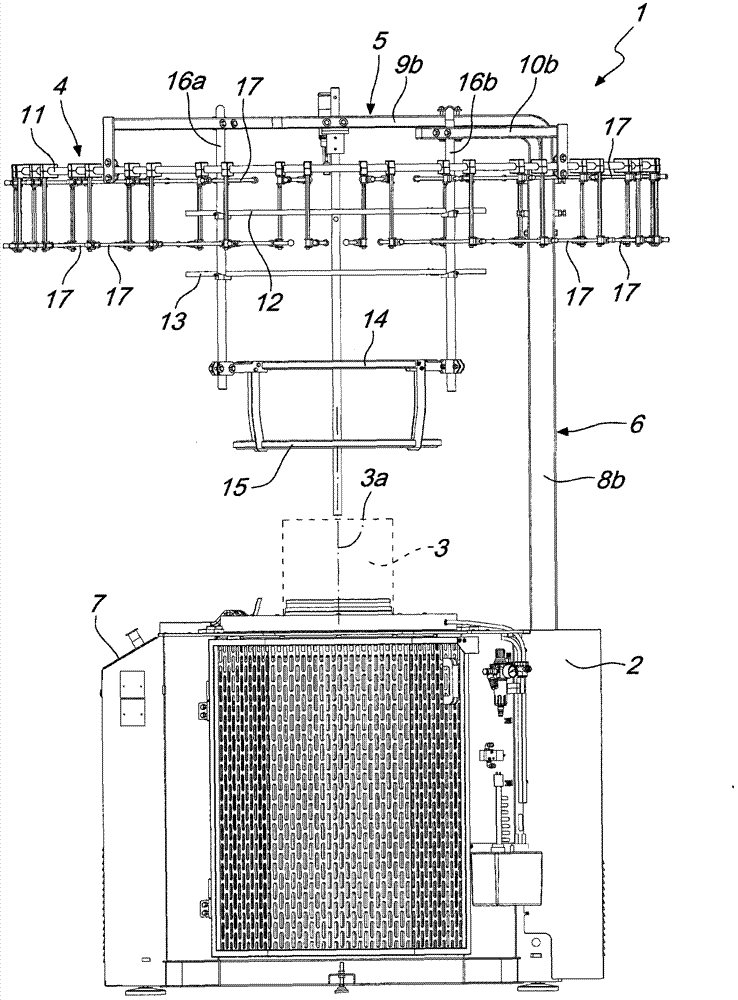

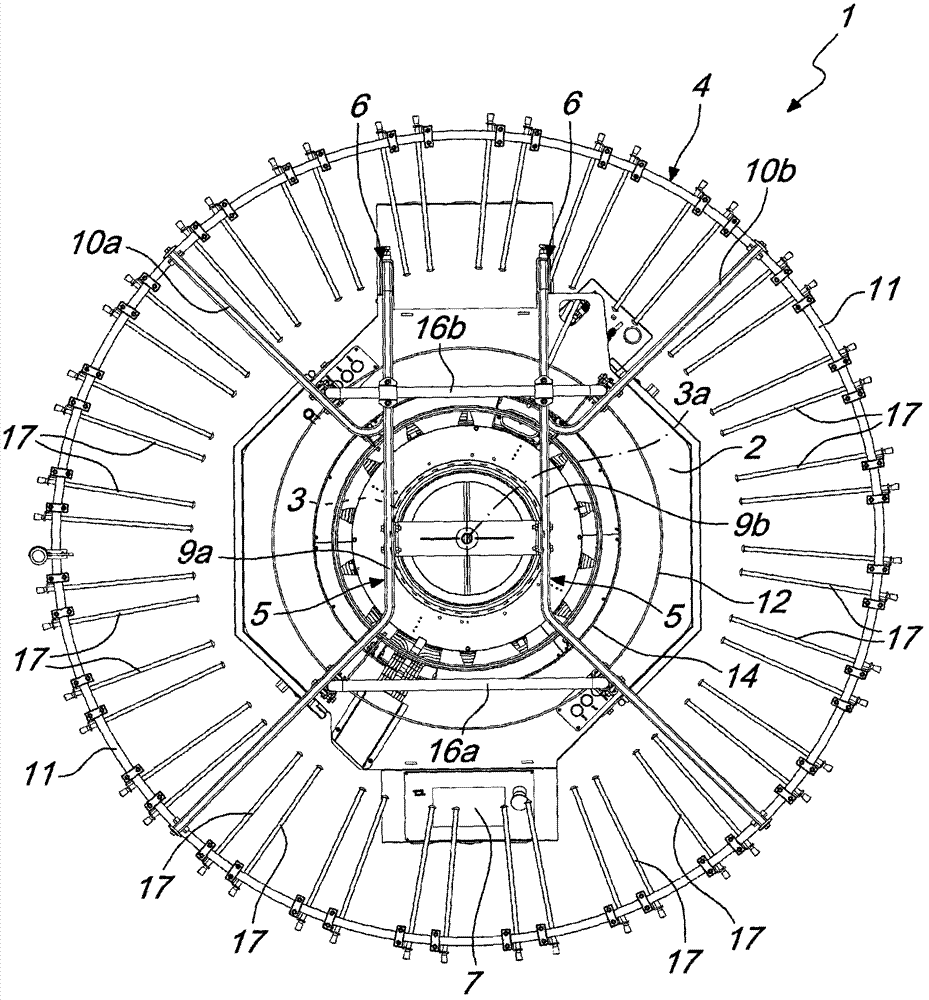

[0019] With reference to the accompanying drawings, a knitting machine according to the invention, generally designated by the reference numeral 1, comprises a foot 2 supporting a cylinder 3 arranged with its axis 3a vertical and capable of is actuated to rotate relative to the foot 2 about its own axis 3a.

[0020] For the sake of simplicity and clarity, the needle cylinder 3 is only shown schematically with dashed lines in the figures, and the following grouped elements such as yarn guides, actuating cams, needle selection devices, etc. , a control device and several actuators and the like, and they surround the upper part of the needle cylinder, and together with the needle cylinder constitute the so-called weaving head of the knitting machine.

[0021] The illustrated embodiment relates to a medium diameter circular knitting machine, but the machine to be described hereinafter is also applicable to small or large diameter, single or double needle bed, double jersey circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com