Direct-current motor armature commutator dynamic pressure overspeed testing machine

A DC motor, overspeed test technology, used in motor generator testing, machine/structural component testing, mechanical component testing, etc. Reasonable, low equipment failure rate, convenient detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

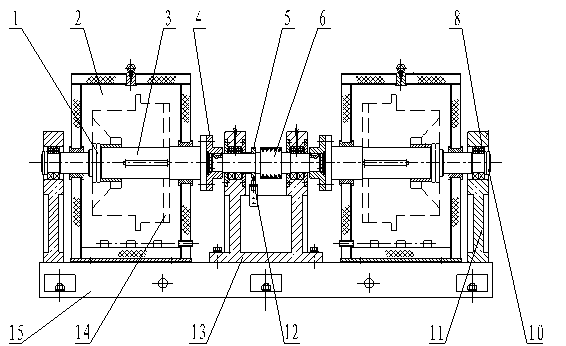

[0010] Such as figure 1 As shown, a double support base 13 is fixed on the platform 15, and the power output shaft 6 is fixed on the double support base 13 through a bearing. 6 is connected with the seams of the dummy shaft 3 provided at both ends of the power output shaft 6 through the flanges 4 on both ends, and the shaft head at the other end of the dummy shaft 3 is fixed on the fulcrum 11 of the dummy shaft through the bearing 8, and locked with a lock The tight nut 10 is locked, and the double support seat 13 and the false shaft fulcrum 11 are composed of Huff semi-bearings; on the platform 15 on the two axial sides of the power output shaft 6, a constant temperature overspeed box 2 is symmetrically fixed, and is located on the power output shaft. The dummy shafts 3 at both ends of the shaft 6 are respectively arranged in the constant temperature overspeed box 2 on both sides of the power output shaft 6, and the dynamic pressure overspeed test can be performed on two comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com