Intelligent transfer device for composite steel strip manufacturing

A transfer device, composite steel technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of occupying space, time-consuming and laborious, increasing the cost of composite steel belts, etc., to achieve reasonable and stable placement and prevent falling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

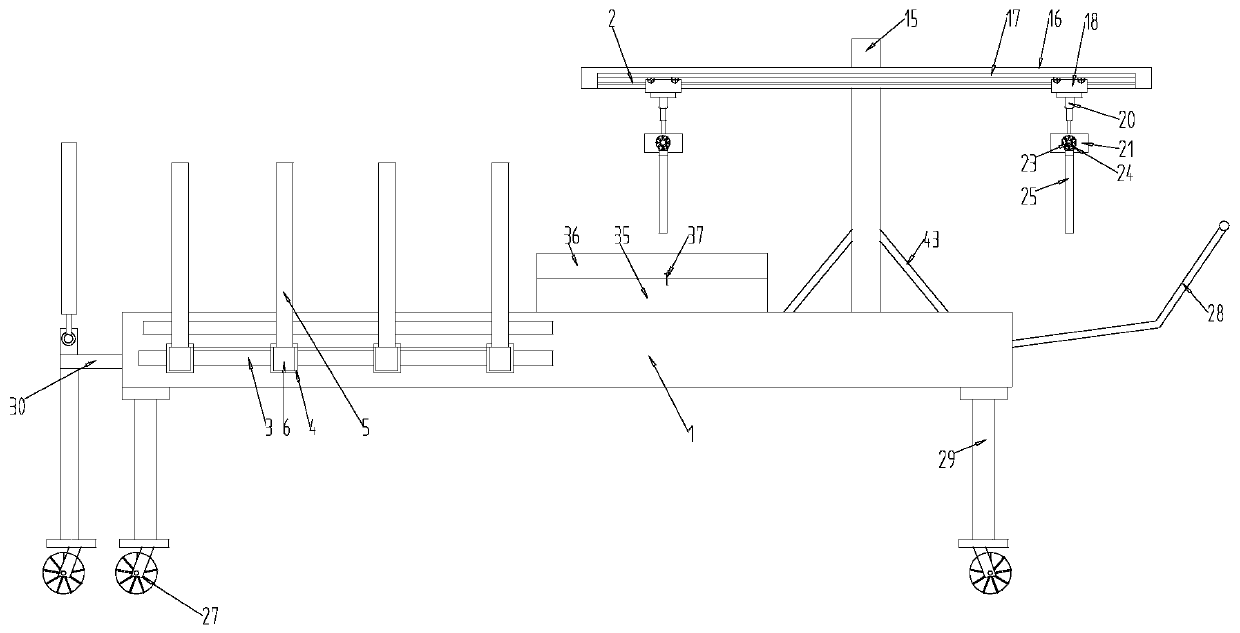

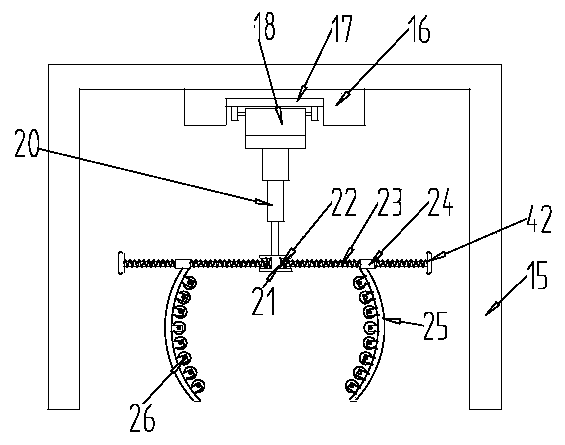

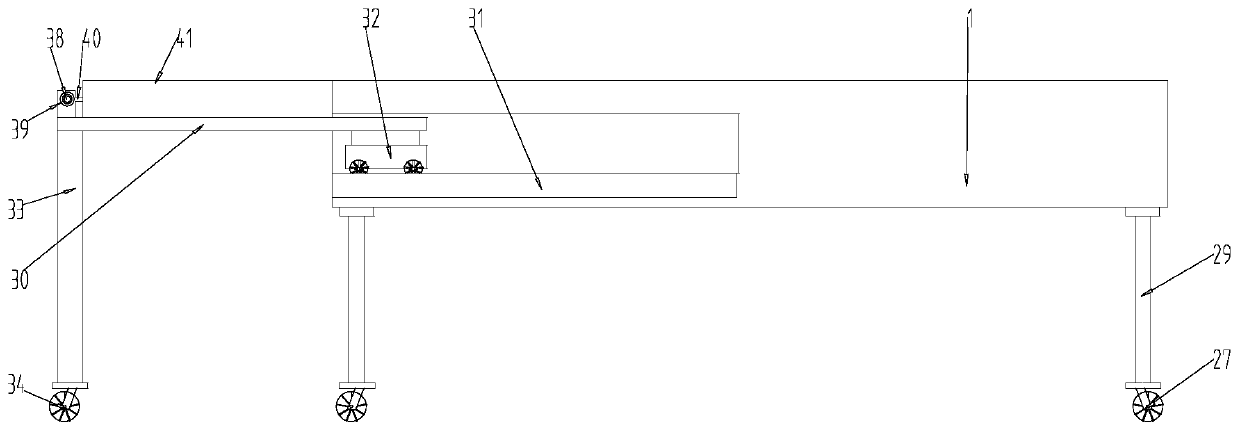

[0031] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6As shown, an intelligent transfer device for the manufacture of a composite steel strip includes a rectangular base 1, and the rectangular base 1 is provided with a storage mechanism, a transport mechanism, a moving mechanism, an extension mechanism, a grabbing mechanism and a blocking mechanism. The moving mechanism is located on the lower wall of the rectangular base 1, the extension mechanism is located in front of the rectangular base 1, and the grabbing mechanism is located above the rectangular base 1; the storage mechanism includes: a pair of support plates 2, a pair of door-shaped Frame 3, several circular rings 4 and several arc-shaped rods 5; the pair of portal frames 3 are arranged on the left and right sides of the left end of the rectangular base 1 respectively, and the several circular rings 4 are respectively fitted with the portal frame On the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com