Fastening system and method for fixing elements on the lining of refrigerators and/or freezers

A technology for cooling equipment and refrigeration equipment, which is applied to household components, household refrigeration devices, lighting and heating equipment, etc., can solve the problems of high manufacturing cost, weaken thermal isolation characteristics, etc., and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

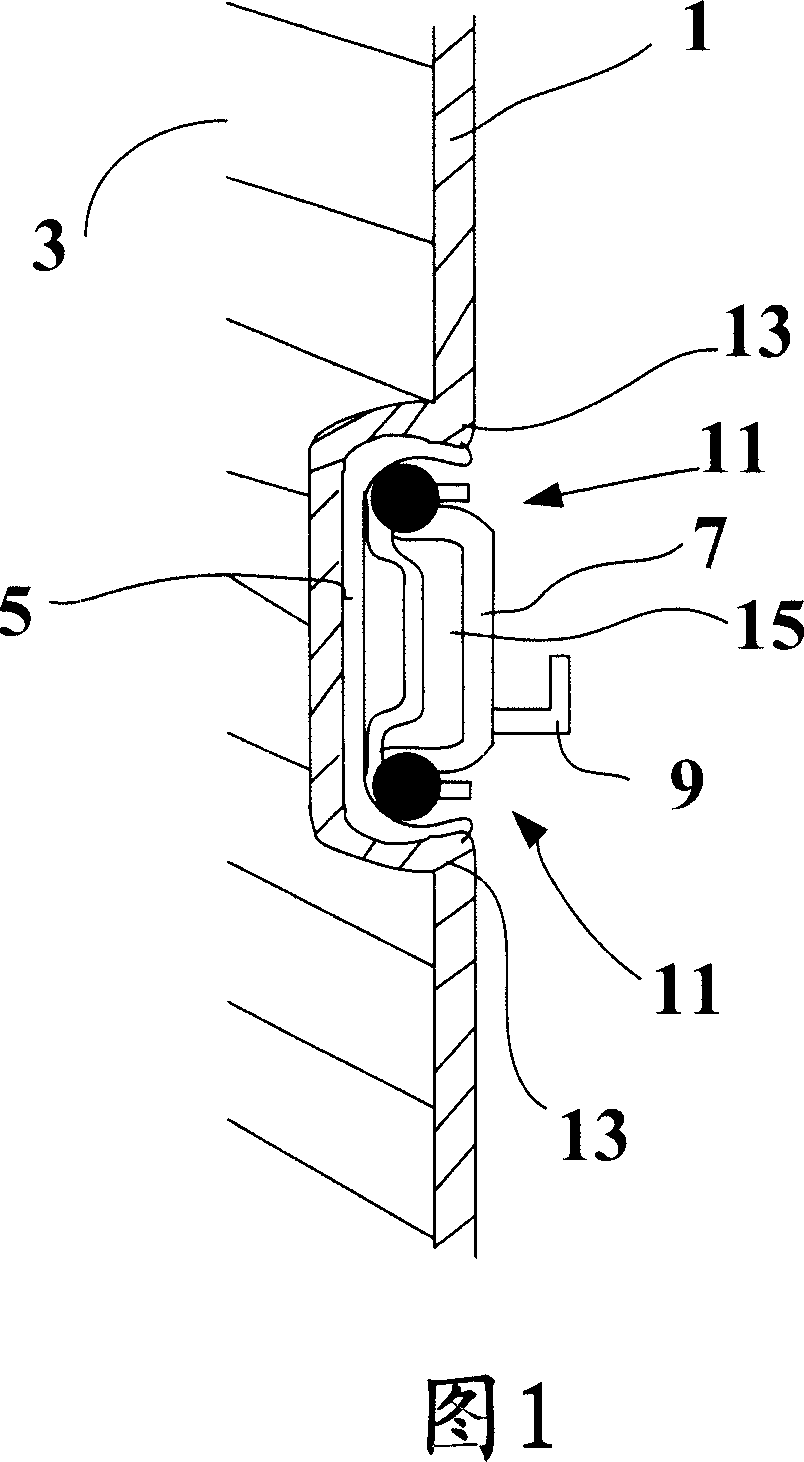

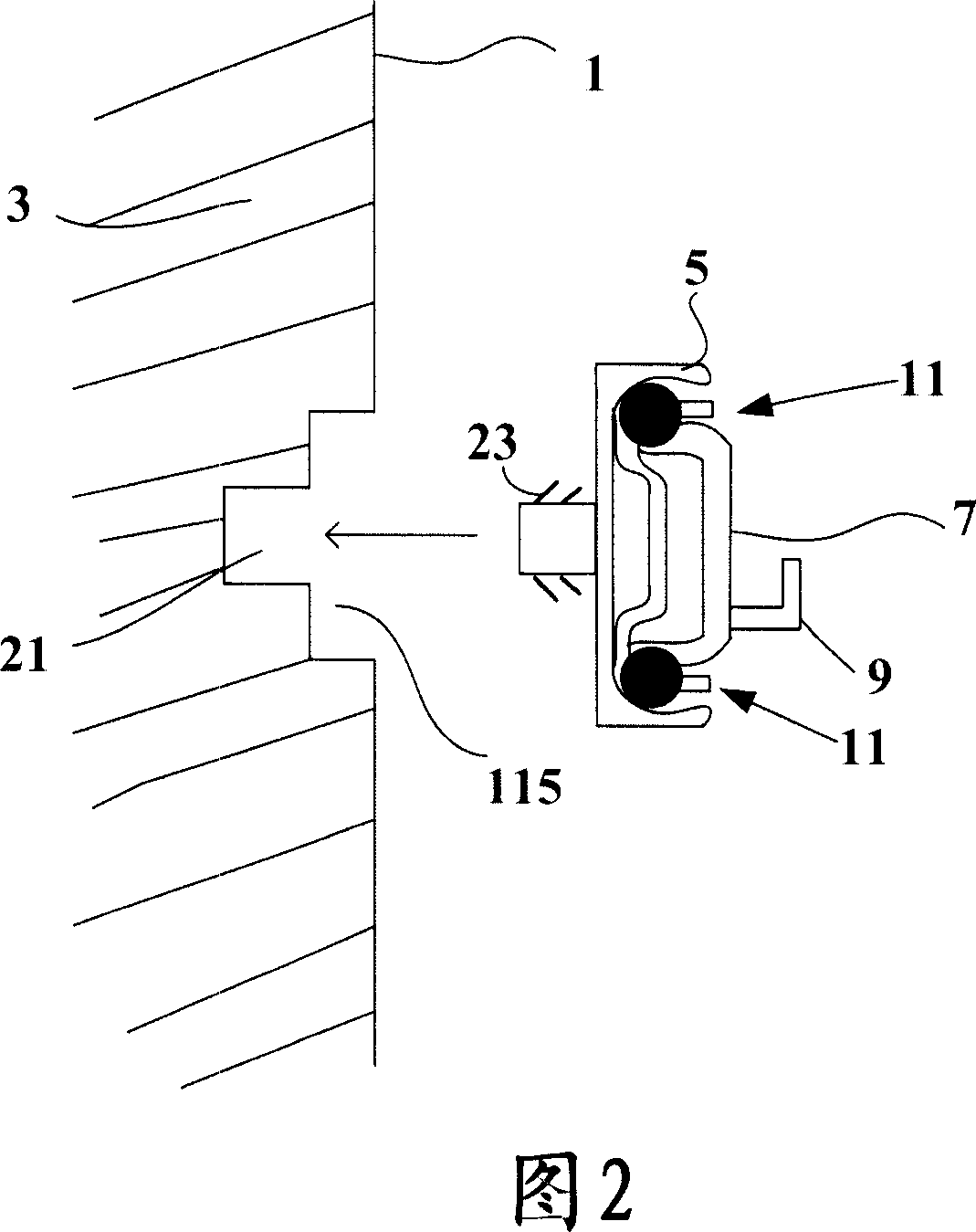

[0023] FIG. 1 shows a cross-sectional view of a mounting device in, for example, a lining or an inner wall 1 of a cooling and / or freezing plant. On the outside of the inner wall 1 a foam insulation 3 is arranged in a manner known per se. A receiving contour 15 formed in the plastic inner wall 1 fits positively into the fastening part of the pull-out rail 5 , which is shown here in cross-section. In the pull-out rail 5 held by a form-fitting connection with, for example, a flange 13, the movable pull-out rail 7 with support means 9 for a pull-out tray or a pull-out drawer is moved by means known per se, such as ball bearings or The other roller bearings move the bearings.

[0024] The pull-out guide rail 5 is mounted substantially flush, enabling easy cleaning of the inner wall 1 . Since the draw-out rail 5 is accommodated in the inner wall 1 , the space available in the cooling chamber is increased and is visually more pleasing than in the case of mounting the draw-out rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com