Method and device for processing containers

A processing device and container technology, applied in liquid processing, packaging, liquid bottling, etc., can solve the problems of inability to obtain uniform and accurate label position, height position change, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

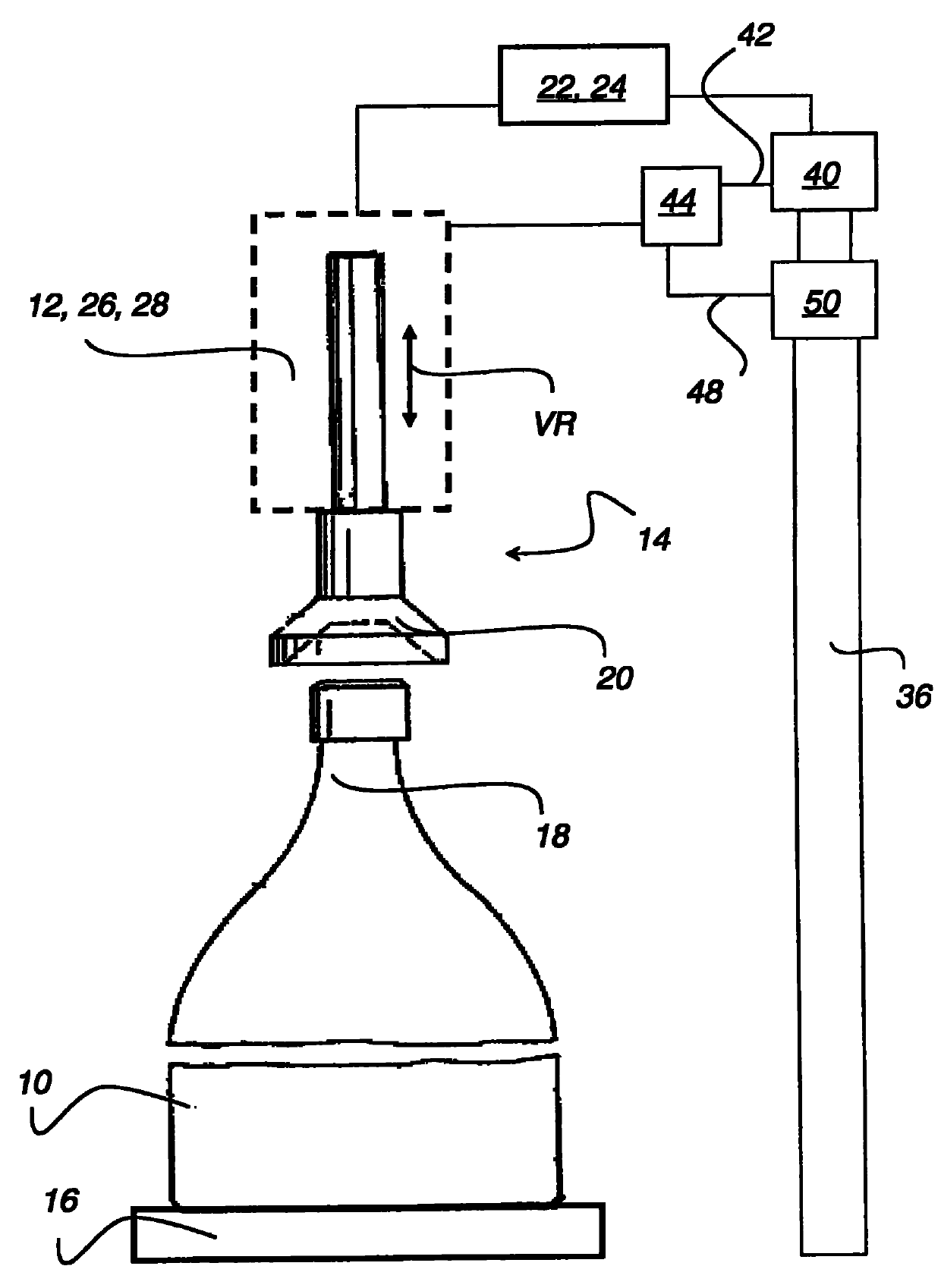

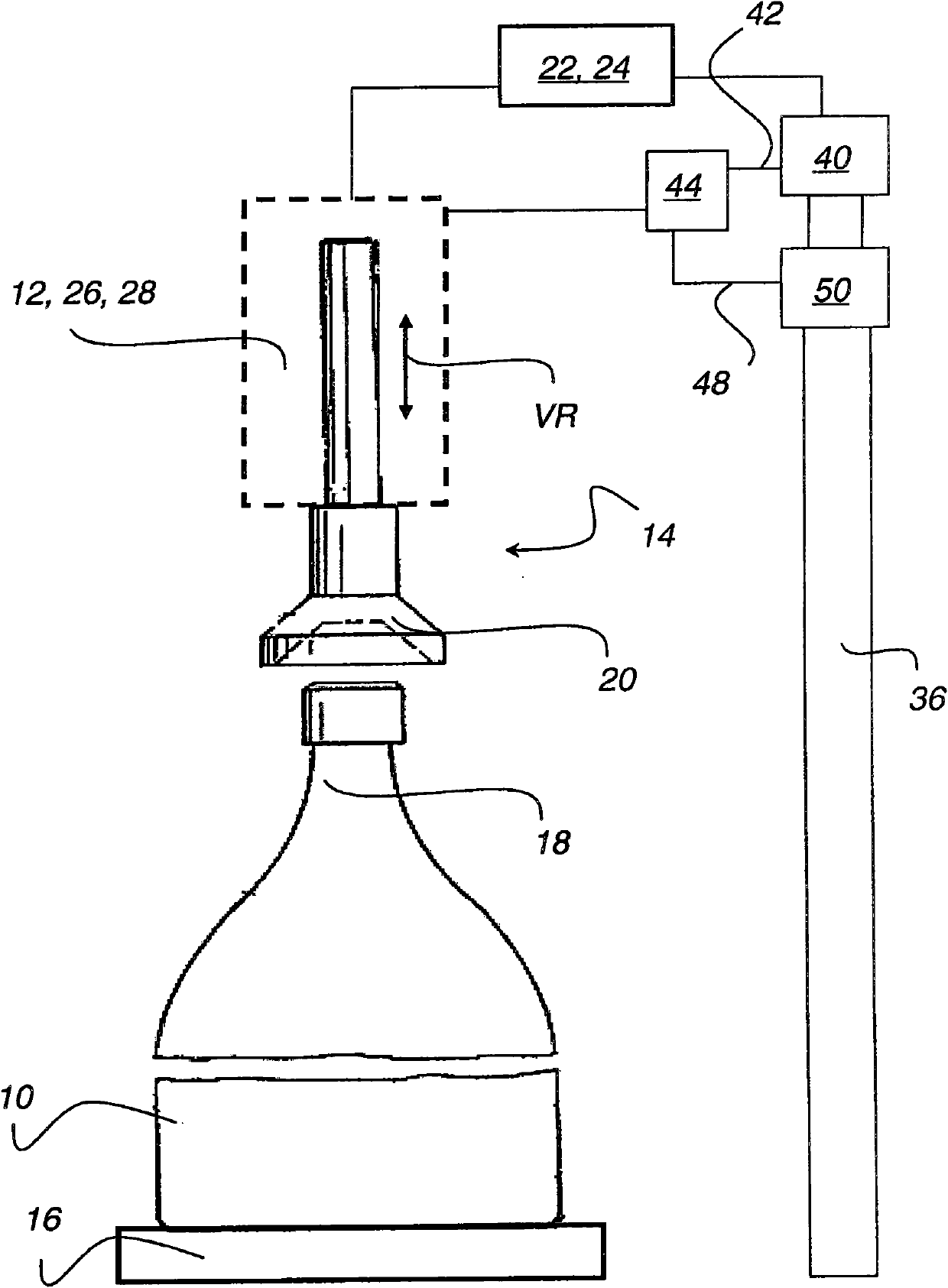

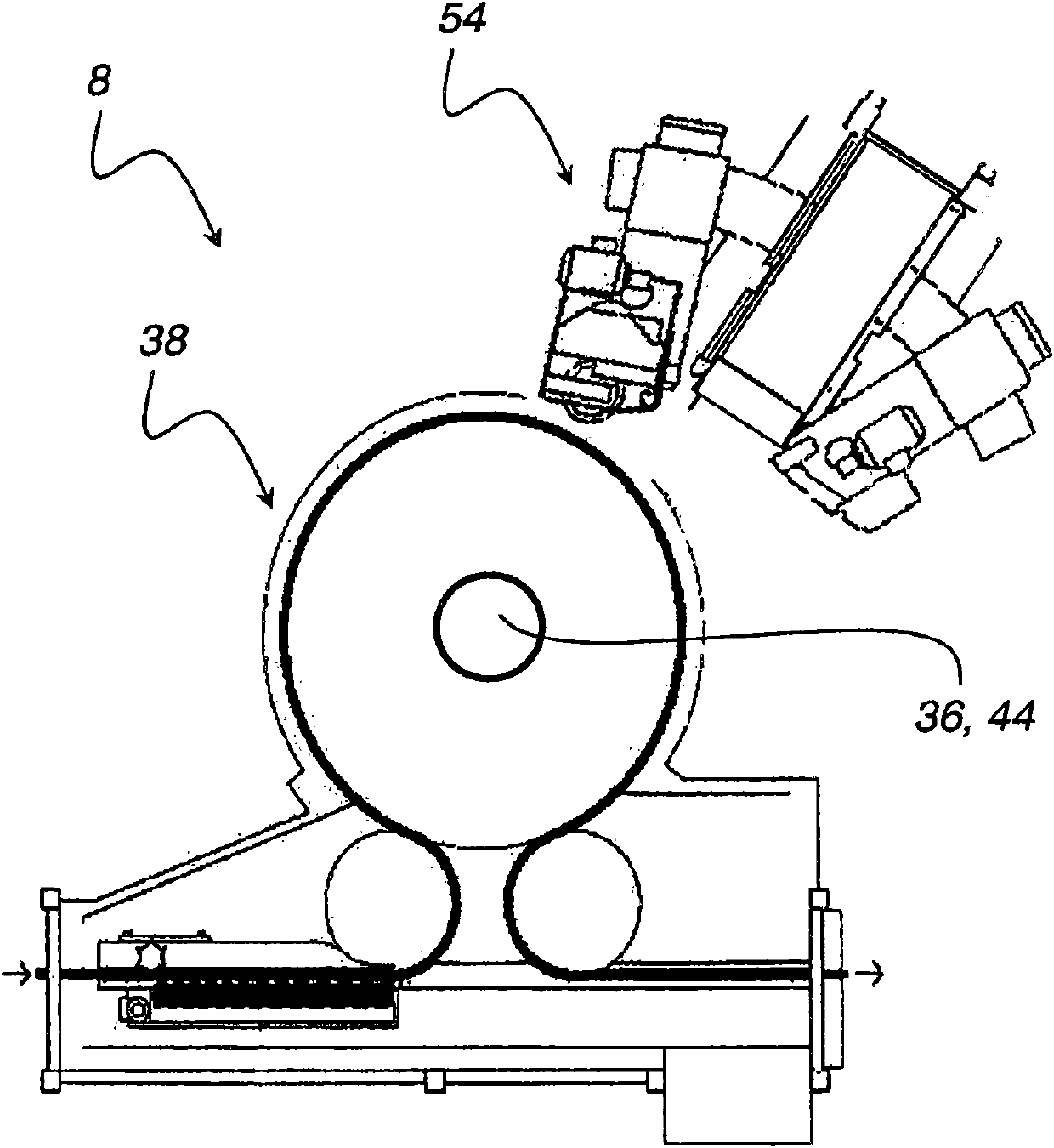

[0028] figure 1 The schematic diagram in the figure clearly shows a typical structure of a container treatment device 8 according to the invention. In the container handling device 8 shown, a plurality of holding devices 14 are arranged in a star shape on a rotatable picking star or turntable 38 and are connected to a central power supply (not shown). exist figure 1 The design shown in the figure corresponds to a large extent with the traditional structure of the container carousel, the basic difference is that there is no curve-or cam guide for mechanically forcing the holding device 14 on the column 36 ( see figure 2 ), because the holding device 14 only utilizes the servo drive 12 (see figure 2 ) can be individually and individually controlled in a desired manner. The container 10 or the bottle is clamped between the holding device 14 and the support 16 (see figure 2 ). The containers 10 each stand on a rotating disk or support 16 and can thus be easily rotated for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com