Floating slab ballast bed with weak correlation between frequency and load

A floating plate, weak correlation technology, applied in the directions of roads, tracks, ballast layers, etc., can solve the problems of limited vibration isolation effect, limited overall vibration isolation effect, large vertical stiffness, etc., and achieve convenient height adjustment and leveling operation. , Improve the overall vibration isolation effect, improve the overall vibration reduction and noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

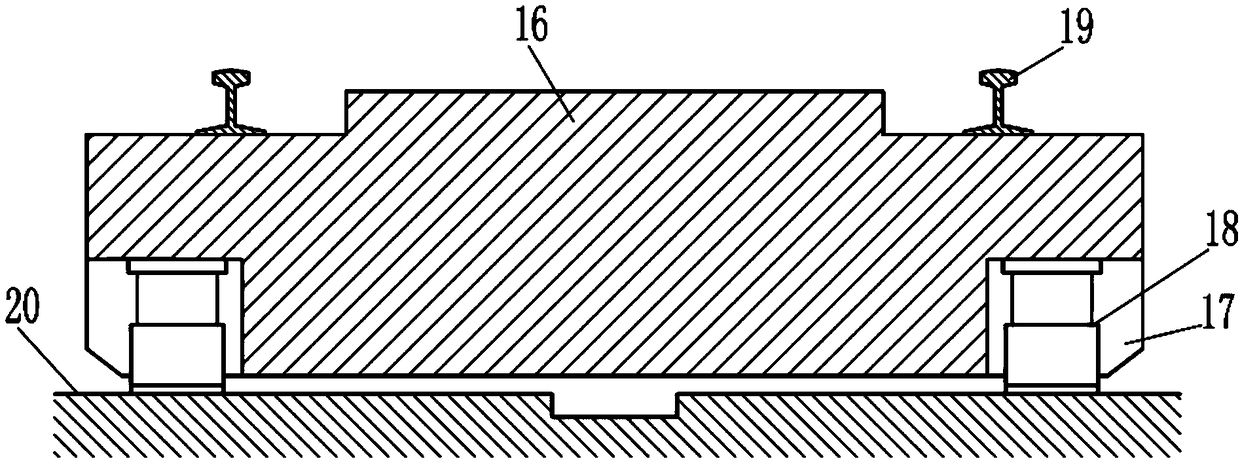

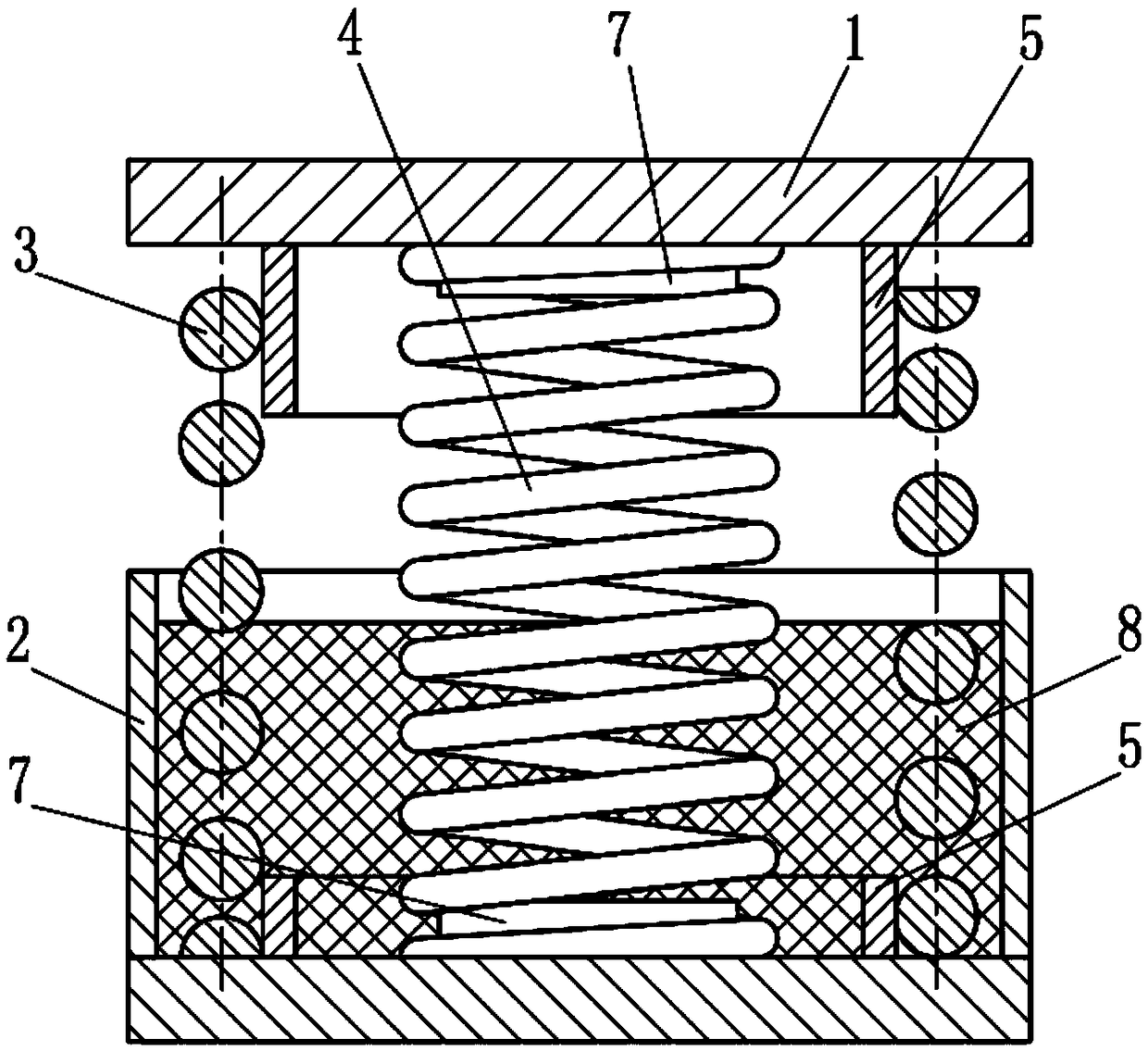

[0027] like figure 1 The floating slab ballast bed of the present invention with a weak correlation between frequency and load includes a floating slab 16 and an elastic vibration isolation device 18, and the elastic vibration isolation device 18 is placed in the reserved space 17 for installation on the floating slab 16, And elastically supports the floating plate 16 to make the floating plate break away from the surface of the foundation 20, and the track structure 19 is arranged on the floating plate; as figure 2 As shown, the elastic vibration isolation device 18 includes an upper shell 1, a lower shell 2 and an elastic element, the elastic element is placed between the lower shell 1 and the lower shell 2, and the elastic element includes a static load supporting spring 4 And joint support spring 3, wherein, static load support spring 4 and joint support spring 3 are helical steel springs, the stiffness of static load support spring 4 is less than the stiffness of joint s...

Embodiment 2

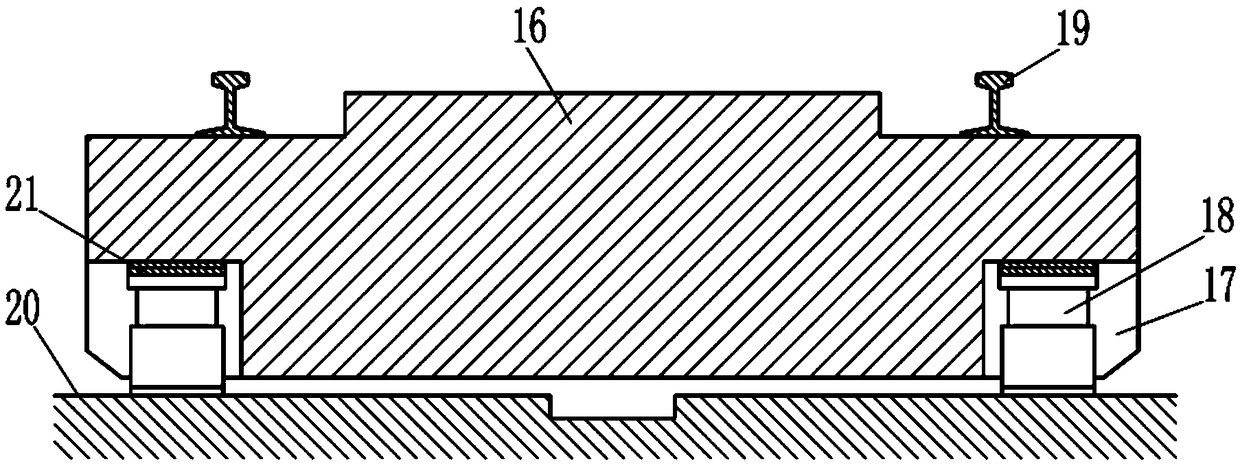

[0033] like image 3 The difference between the floating slab ballast bed of the present invention with a weak correlation between frequency and load as shown in Embodiment 1 is that it also includes a height-adjusting gasket 21, which is arranged between the floating slab 16 and the elastic vibration isolation device 18 ; In addition, if Figure 4 As shown in this example, in the elastic vibration isolation device of the floating slab ballast bed with weak correlation between frequency and load described in this example, a solid damping structure is provided on the partial surface of the static load support spring 4 of the ballast bed, and the solid damping structure is specifically set in the static load The rubber sleeve 9 on the partial outer surface of the support spring 4; in addition, the support 6 for height compensation is arranged under the static load support spring 4, and the support 6 is fixedly connected with the lower housing 2 as a whole. At this time, the stat...

Embodiment 3

[0036] like Figure 5 The difference between the floating slab ballast bed of the present invention with a weak correlation between frequency and load as shown in Embodiment 2 is that a coupling sleeve 22 is fixedly arranged on the floating slab 16, and the elastic vibration isolation device 18 is placed in the coupling sleeve 22. The elastic vibration isolation device 18 is supported on the support block 23 of the connecting sleeve 22 through the height-adjusting spacer 21, so that the floating plate 16 is separated from the surface of the foundation 20. In addition, in order to prevent foreign matter from falling into the connecting sleeve, the top of the connecting sleeve An end cover 24 is provided; in addition, the arrangement of the solid damping structure on the surface of the static load bearing spring can be various, such as Image 6 As shown, in the elastic vibration isolation device adopted in this example, a rubber layer 10 is integrally provided on the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com